Self Test error X-Axis Length

I finished assembling my Mk3 today and went to run the calibration wizard. Everything was fine until it started running the X-axis.

Starting from the center it went to the right, then back to the center and failed.

I tried again with it starting on the far left and it went the full distance, went half way back and then failed.

Re: Self Test error X-Axis Length

There is another long post about this, you can search it for more information.

So far two common causes are identified:

1. wires on either side (esp. the wire of the left side fan ) are bulging, causing resistance to the movement of the extruder at the ends.

(I committed this one. I THOUGHT my wire were snug enough, but in fact not. It has to be perfect.)

2. Back cover of the extruder is too tight, loosen the back screws can help.

Re: Self Test error X-Axis Length

The alignment of the zip ties on the umbilical can cause this if not orientated correctly. Make sure the sticky-out bits are all above the wires and not to one side.

Re: Self Test error X-Axis Length

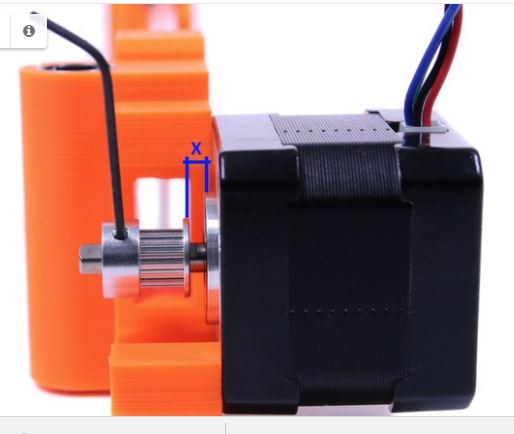

I looked and found the pulley on the X-axis motor side was pressed against the casing.

After shimming the motor with some square nuts i re-ran the test.

This time it traveled to the far left, then all the way to the right and back, but it still gave me an X-axis length error

Re: Self Test error X-Axis Length

hi Michel,

have you got the X motor pulley on back to front?

the grub screw should be on the opposite side of the belt to the motor... ie thick flange towards the end of the shaft!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Self Test error X-Axis Length

It turns out i did have that part reversed.

Unfortunately correcting that hasn't solved the issue.

Re: Self Test error X-Axis Length

I noticed one of the zip ties was hitting when it moved to the right side.

That was the problem

Re: Self Test error X-Axis Length

I had the same issue after building the MK3:

This is what I did to resolve..

I recommend you read first and understand the steps as they can be a pain, but I think I've outlined them well enough.

If you decide to try this, please use caution and if any step does not make sense or 'feel' good, then stop !

- remove the filament for this proceedure

- remove all the zip ties from the wire bundle on the back of the extruder.

- unplug the Molex (Black) connector from the top of the extruder

- take out the 5 screws holding the back plate on the backside of the extruder

- pull back the spiral plastic shield and allow the back plate to pull back about 3/4 inch

- unscrew and remove the X-Axis stepper motor

- remove the belt and set it aside for now

- working from the back of the unit now , so you should be looking at the backside of the extruder

- push the extruder all the way to the stepper motor side, be careful to position the extruder plastic back part that is hanging so it does not hit anything, also be sure all the wires are kinda in the center to allow the extruder to be pushed completely until it stops..

- slide the extruder gently back and forth on the stepper motor end and it should be 'very' free gliding with NO hesitation.

- if there is any binding then you may have to remove the zip ties on the bearings and replace, but this time keep them a little looser.

- with the extruder pushed fully to the Stepper motor end again check for very free movement.

- again if still seems like it is binding, the push the extruder up against the stepper motor end again

- if you still find some binding, then hold the extruder (from the front side) and turn it slightly clockwise then counter clockwise, this is th melp the bearings find their seating with-in the plastic , CAUTION: do not use 'gorilla' force a simple firm hand to help seat the bearings is all you need, and only turn it a couple times..

- now the movement is completely free moving, NO binding...

- pull the extruder a few inched from the stepper motor end, just enough to let you re assemble the back plastic plate and put the screws back in

- put the Belt back on, per the assembly instructions and leave it free from the motor at this point

- align the filament sensor wire in the provided channel on the plastic back side.

- gently push the plastic back in place and align the wires by hand right now..

- plug in the Molex (black) connector back in to the sensor pins, and be sure the top wires are tucked inside not to hit the FRAME in the next steps

- insert the 'center' screw to hold the plastic back in place

- ensure all the wires are kinda in place so you can slide the extruder back to the stepper motor side once again.

- be sure the extruder STILL moves freely ALL the way to the stepper motor stop, and there is not binding.

- if this is ok then move it back to the center of the X axis to resume dressing out the wiring bundle.

- make sure your spiral sleeve and wires are all in the correct positions

- insert the 3 zip ties ( as directed in the assembly instructions) and gently tie off the bundle leaving the zip tie 'knot' a the very TOP of the bundle, so it does not hit the frame when pushed side to side. (DO NOT TIGHTEN these down or cut them yet)

- now insert the 2 bottom zip ties to hold the heater wires at the bottom

- also keep the zip tie 'knot' at the BOTTOM of the bundle this time, gently pull them tight, but leave a little extra after you cut so you can re tighten if needed

- now push the entire extruder from side to side and there should be NO binding when you get to the ends on either side.

- you should have a really good feeling that this is MUCH Better now.

- you can tighten the bottom Zip ties, but again, no need for any gorilla force, we are just trying to keep them in place.

- Finally: you can insert the last for screws into the back plastic panel.

- Start with the top two screws and tighten when you feel them start to tighten up, STOP.

- Again, test the extruder, slide from SIDE TO SIDE. should be ok still.

- Now insert the bottom two scres in the back plastic panel and again, when you feel them start to tighten up, STOP.

- Again, test the extruder, slide from SIDE TO SIDE. should be ok still.

- Replace the X-axis motor per assembly instructions and tighten down

- be sure you have the gear tightened if you loosened it up also.

- trim any zip ties if needed

-now you are done.

Goto CALIBRATION- SELFTEST and run this,, should pass just fine

Next CALIBRATION - XYZ and run this

finally do the FIRST LAYER CALIBRATION and now you are ready to print .

hope this helps.....

Chuck

Re: Self Test error X-Axis Length

I found that one of the tie wraps, the one closest to the motor was causing issues. Even with the largest part out of the way the thickness of the wrap was causing it to fail. Cut it out and all is well.

Re: Self Test error X-Axis Length

I had the same issue after building the MK3:

This is what I did to resolve..

I recommend you read first and understand the steps as they can be a pain, but I think I've outlined them well enough.

If you decide to try this, please use caution and if any step does not make sense or 'feel' good, then stop !

[...]

hope this helps.....

Chuck

Hi Chuck,

thanks for dropping this here - it was most helpful to me fixing my issues. Very much appreciated!!!

Kind regards,

Flo

Re: Self Test error X-Axis Length

There seems to be an error in the instructions which cause this X-axis Length error. Chapter 5 step 44 - Tightening the spiral wrap (Part 1) shows a zip tie tightened on the side of the cable holder. This zip tie clasp hits the power supply during the x-axis test and results in an error. To clear the error all I had to do was move the zip tie clasp under the cable holder. Hope this helps.

Re: Self Test error X-Axis Length

Hi Chuck, thanks for the thorough troubleshooting instructions.

Unfortunately I still get a "Selftest error Please check: Axis length Axis X"

It seems that the extruder is hitting the left "stop" clean and clear. The black left side of the carriage squarely contacts the orange cylindrical body below the lead screw nut. Clunk! No wires or zip ties are making contact.

The right side however does not seem to make clean contact with anything. It seems like the soft PINDA probe cable is the first thing to make contact. It hits and pinches the edge of the metal frame. Does the mk3 even care about this? Is it truly using physical contact to detect the right -most extent of the x axis? There's no way I can see in any photos out there to get the PINDA cable out of the way. It goes through its little plastic guide/channel and exits to the rear directly into harms way, on a collision course with the right inner edge of the frame.

Please let me know your opinion.

Thanks!

EDIT: Problem solved, I figured it out! ALL the cables need to go through the pass-through hole in the back of the extruder - except the filament sensor and the nozzle heater and thermistor. Once I routed all the right cables through the cable channels and through the hole out the back of the extruder I passed all my self tests! Woohoo! 😀

Re: Self Test error X-Axis Length

Same issue here. The zip tie head was hitting the PSU and preventing movement all the way to the right. Moved the zip tie a bit and the test passed.

------------------------------------------

Prusa I3 MK3S

Re: Self Test error X-Axis Length

I tried everything without any luck, short of belts, etc in that very long reply earlier.

I would pass Z axis calibration, but fail on Selftest on x axis length calibration. On the XYZ, I would fail on point 3/4 in the rear right position.

I took off my flexible wiring harness ( ). I removed ALL the zip ties after the one closest to the extruder didnt work. Then I back out 5 of the screws on the rear without any help. Then I taped and tried to adjust the PINDA wiring so it was perpendicular to the extruder and didn't touch the frame or the belt at all. Then I removed all of them without any luck. I ran the Self Test Wizard (failing on X Length Calibration) and the XYZ (failing on step 3/4) continually and it would fail each and every time at the exact same spot.

In the meantime, Prusa support said that potentially it was a belt tightness issue - if the belts are too loose or too tight. Support->Belt status X 274, Y 301. Both were too loose (the numbers should be lower and ideally 250 for each. A higher value = looser belts. I didnt change the belt tension

MEANWHILE when screwing around with changing the height of the carriage using the screws when adjusting the PIDA sensor, I changed what I did and used a paper. Bingo!

FINALLY, I was finally able to do XYZ after using a paper and sliding it under the nozzle when doing the PINDA sensor. When the paper didnt slide at all, I raised the height of that side JUST A SMALL AMOUNT, then I slide the carriage to the right side and did the same. The nozzle wouldnt drag on the paper. Then I used the paper with the Zip tie and BINGO it worked.

Re: Self Test error X-Axis Length

I tried everything without any luck, short of belts, etc in that very long reply earlier. I looked at Prusa's list of recommendations ( https://help.prusa3d.com/article/fja7hbb22y-xyz-calibration-error-messages-mk-3?code=400&failed=1&reason=Multilingual+is+not+enabled+on+this+account#_ga=2.77932628.1324918485.1544765808-1851702805.1528238698 )

I would pass Z axis calibration, but fail on Selftest on x axis length calibration. On the XYZ, I would fail on point 3/4 in the rear right position.

I took off my flexible wiring harness ( ). I removed ALL the zip ties after the one closest to the extruder didnt work. Then I back out 5 of the screws on the rear without any help. Then I taped and tried to adjust the PINDA wiring so it was perpendicular to the extruder and didn't touch the frame or the belt at all. Then I removed all of them without any luck. I ran the Self Test Wizard (failing on X Length Calibration) and the XYZ (failing on step 3/4) continually and it would fail each and every time at the exact same spot.

In the meantime, Prusa support said that potentially it was a belt tightness issue - if the belts are too loose or too tight. Support->Belt status X 274, Y 301. Both were too loose (the numbers should be lower and ideally 250 for each. A higher value = looser belts. I didnt change the belt tension. Good steps that describe that are here ( https://manual.prusa3d.com/Guide/4.+Z-axis+assembly/509?lang=en#s9981 and Y axis belt https://manual.prusa3d.com/Guide/2.+Y-axis+assembly/507?lang=en#s8225 ). Reportedly the Support->Belt status values update after passing the self test.

MEANWHILE when screwing around with changing the height of the carriage using the screws when adjusting the PIDA sensor (Step 9, Preflight check, https://manual.prusa3d.com/Guide/9.+Preflight+check/514 ), I changed what I did and used a paper. Bingo!

FINALLY, I was finally able to pass the XYZ calibration after using a paper and sliding it under the nozzle when doing the PINDA sensor height adjustment (step 9,Preflight). When the paper didnt slide at all, I raised the height of that side JUST A SMALL AMOUNT, then I slide the carriage to the right side and did the same. The nozzle wouldnt drag on the paper. Then I used the paper with the Zip tie and BINGO it worked.

TL;DR: Use a paper under the PINDA height adjust process when moving the extruder (Step 9, Preflight). Rotate the threaded rods down until it contacts the paper and prevents it from sliding. Then raise it just a little bit so it slides without much/any resistance. Repeat for the right side. Move to the center and use a paper on the bed when also using the PINDA sensor adjustment with the zip tie. Also consider the tension on the belts, try for 250 (lower number -> tighter). Getting belt tension down to 260 or 250 would be ideal, just dont break something.

[/b]

Re: Self Test error X-Axis Length

After doing a few times with intermittent success, it seems that having potentially 2-3 sheets may be more reliable. Give it a shot! =)

Re: Self Test error X-Axis Length

I had this issue too on first self test.

Turned out to be something as simple as the ends of the zip ties fouling the sides of the printer at the extremes of the x-axis.

Solved by simply rotating the zip ties so that the protruding cut ends were sticking out vertically rather than horizontally and this solved the problem.

Worth trying this first as it is a 5 second fix.

Re: Self Test error X-Axis Length

One thing to remember is that there are two different testing "programs" within the Prusa i3 mk3:

A) The "Wizard", which resets all of your parameters and starts over from scratch.

B) The "Self Test" which maintains everything until the program completes, akin to how the XYZ tests are performed.

It's not a big deal, but I was a little leary of getting in a situation that would prevent me from being able to pass a calibration test and prevent any printing. The "Self Test" is more flexible.