Reading G81 output

Hello,

Working up a tool to drop G81 output into and get a nice visual representation of what's going on. If I had the following G81 output...

0.10083 0.25583 0.37111 0.44667 0.48250 0.47861 0.43500

0.13852 0.19855 0.25244 0.30019 0.34179 0.37725 0.40657

0.16352 0.15441 0.16219 0.18685 0.22840 0.28682 0.36213

0.17583 0.12343 0.10037 0.10667 0.14231 0.20731 0.30167

0.17546 0.10559 0.06698 0.05963 0.08355 0.13873 0.22519

0.16241 0.10090 0.06201 0.04574 0.05210 0.08108 0.13269

0.13667 0.10935 0.08546 0.06500 0.04796 0.03435 0.02417

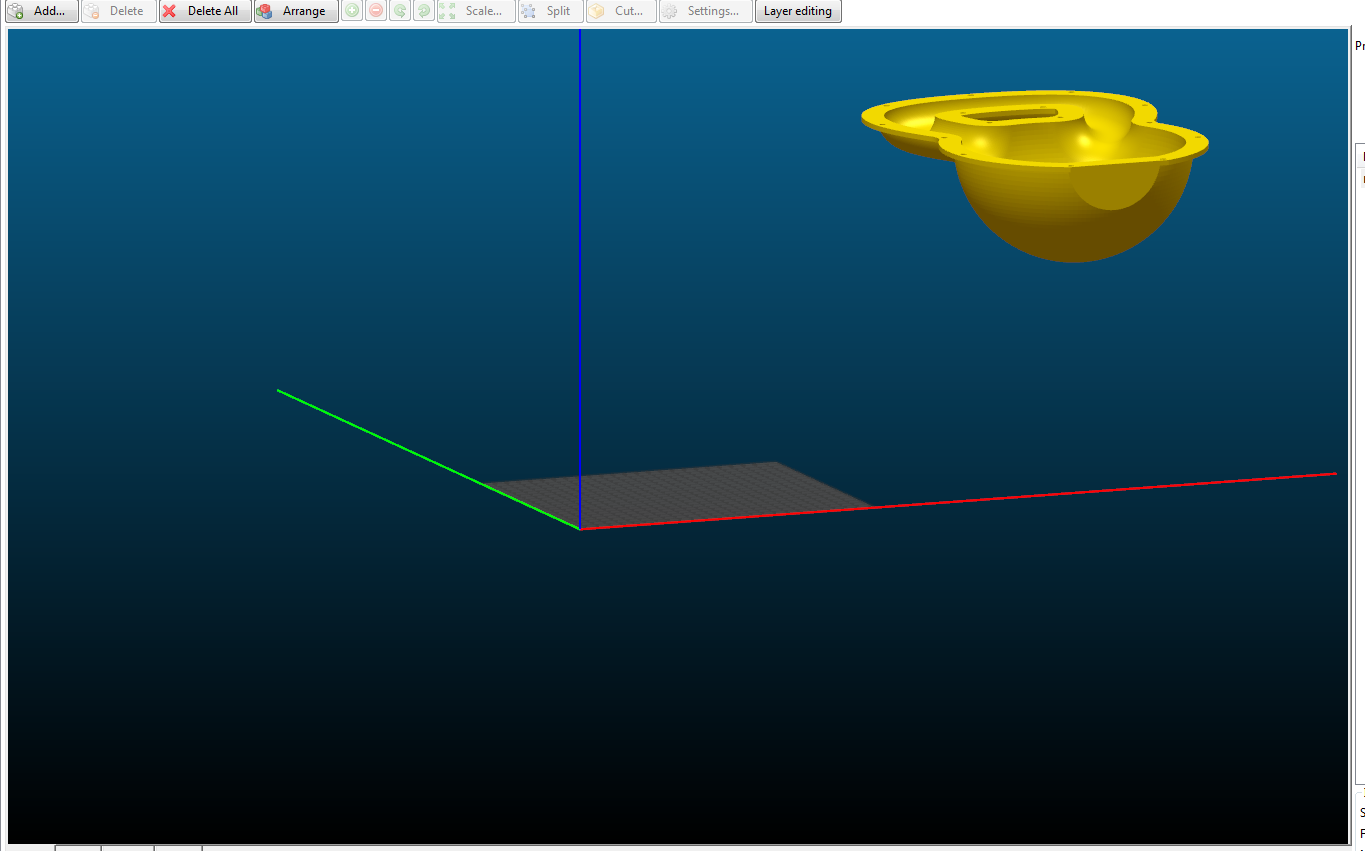

Is this read like it looks on the screen? Top rows are the rear of the bed, left rows are left, etc? I was able to use the above output to get the following:

Figured this may be handy before I start installing my shims.

Thanks!

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Reading G81 output

Very nice tool!

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: Reading G81 output

You could try installing a large shim and see where the output changes?

Re: Reading G81 output

Hello,

Working up a tool to drop G81 output into and get a nice visual representation of what's going on. If I had the following G81 output...

0.10083 0.25583 0.37111 0.44667 0.48250 0.47861 0.43500

0.13852 0.19855 0.25244 0.30019 0.34179 0.37725 0.40657

0.16352 0.15441 0.16219 0.18685 0.22840 0.28682 0.36213

0.17583 0.12343 0.10037 0.10667 0.14231 0.20731 0.30167

0.17546 0.10559 0.06698 0.05963 0.08355 0.13873 0.22519

0.16241 0.10090 0.06201 0.04574 0.05210 0.08108 0.13269

0.13667 0.10935 0.08546 0.06500 0.04796 0.03435 0.02417

Is this read like it looks on the screen? Top rows are the rear of the bed, left rows are left, etc? I was able to use the above output to get the following:

test.png

Figured this may be handy before I start installing my shims.

Thanks!

Yes. you are reading the arrangement correctly. I don't remember the direction of the measurement 100% but my recollection is that it can be read that higher numbers are UP and lower numbers are DOWN. The back, rear of the bed is too high so the front of the right Y guide rod needs to come down.

Re: Reading G81 output

You could try installing a large shim and see where the output changes?

The induction spots used by pinda are on the heatbed, not the magnetic sheet on top. Inserting a shim in between won't change the output

Re: Reading G81 output

The induction spots used by pinda are on the heatbed, not the magnetic sheet on top. Inserting a shim in between won't change the output

I think you are mistaken. I think the probe triggers on both the spots, and the magnetic sheet. I may be wrong, and I'm not close to a MK3 so I can test - but to verify, just look at the light on the probe - does it change only over the induction spots, or also when close to the flexible bed? Can you trigger it with any piece of metal?

Re: Reading G81 output

Zaz is right, the probe measures the distance down to the sheet bed.

I have used the same method to shim the bed on my MK3 and it works very well.

Bear MK3 with Bondtech extruder

Re: Reading G81 output

I have confirmed the orientation. I am using https://www.amazon.com/gp/product/B00PGHX67Q these little guys between the heat bed and the standoffs and they seem to be working nicely. Just takes a lot of time and a lot of patience.

At this point I am really wondering about some way to replace the edge bed standoffs or augment them with something very rigid but flexible enough that this can be adjusted by screws alone.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Reading G81 output

I think you are mistaken. I think the probe triggers on both the spots, and the magnetic sheet. I may be wrong, and I'm not close to a MK3 so I can test - but to verify, just look at the light on the probe - does it change only over the induction spots, or also when close to the flexible bed? Can you trigger it with any piece of metal?

Indeed, it triggers by the sheet too. Glad about being wrong this time 😀

Re: Reading G81 output

I think PINDA temperature is a good addition to the dataset, available via M105 parameter P. Take a reading before calibration and after it, to verify the PINDA temp was stable (and what it was)

More details about what PINDA is doing can be had by compiling a custom firmware with DEBUG_DCODES which gives access to D8 command. Not sure if reported information is useful, tho.

Also in my limited testing the numbers reported by G80/81 differ quite a lot from run to run. Not sure how to interpret that.

Re: Reading G81 output

At this point I am really wondering about some way to replace the edge bed standoffs or augment them with something very rigid but flexible enough that this can be adjusted by screws alone.

Unfortunately, there is no space for any nut or screwhead to adjust the bed. There is only 1 to 2.5 mm of space under the frog.

However, replacing the spacer sleeves with small, powerful springs would make it possible to adjust the bed by means of the existing screws, but only by removing the steel sheet to access the screws.

Bear MK3 with Bondtech extruder

Re: Reading G81 output

I think PINDA temperature is a good addition to the dataset, available via M105 parameter P. Take a reading before calibration and after it, to verify the PINDA temp was stable (and what it was)

More details about what PINDA is doing can be had by compiling a custom firmware with DEBUG_DCODES which gives access to D8 command. Not sure if reported information is useful, tho.

Also in my limited testing the numbers reported by G80/81 differ quite a lot from run to run. Not sure how to interpret that.

Sorry for the OT, but maybe you know if there is a way to wait for PINDA temp ? (like M109 waits for extruder temp)

Best regards... Szafran... MK3S + MMU2S + OctoPrint on DELL 3020m