Print quality question

First the good news on print quality: bridging and overhangs are printing very nicely.

Now my issues: I'm seeing two print quality issues with my MK3:

1-On corners, I'm seeing tiny gaps in random layers. Not sure what might cause this.

2-I'm also seeing some feature echoing around cutouts/holes. Am I nit-picking?

I'm using Slic3r PE factory settings except for two changes to try to get rid of the problem: External Perimeters First is checked, and Seam Position is set to Random. Other than that I'm using default PLA settings, .15mm OPTIMAL, and Prusa silver filament.

Below are pictures of two of the corners (all 4 have it), and some echoing around screw holes and a cutout. Ideas?

[BTW: I'm trying to include images using dropbox links and they don't seem to display for some reason - Sorry]

Re: Print quality question

1-On corners, I'm seeing tiny gaps in random layers. Not sure what might cause this.

2-I'm also seeing some feature echoing around cutouts/holes. Am I nit-picking?

first, quick tip on dropbox. reformat your links like this:

to get a direct link to the image that will work with the forum img tags and display properly. Dropbox stopped allowing direct linking a long time ago, but thats a workaround that still works.

now your issues:

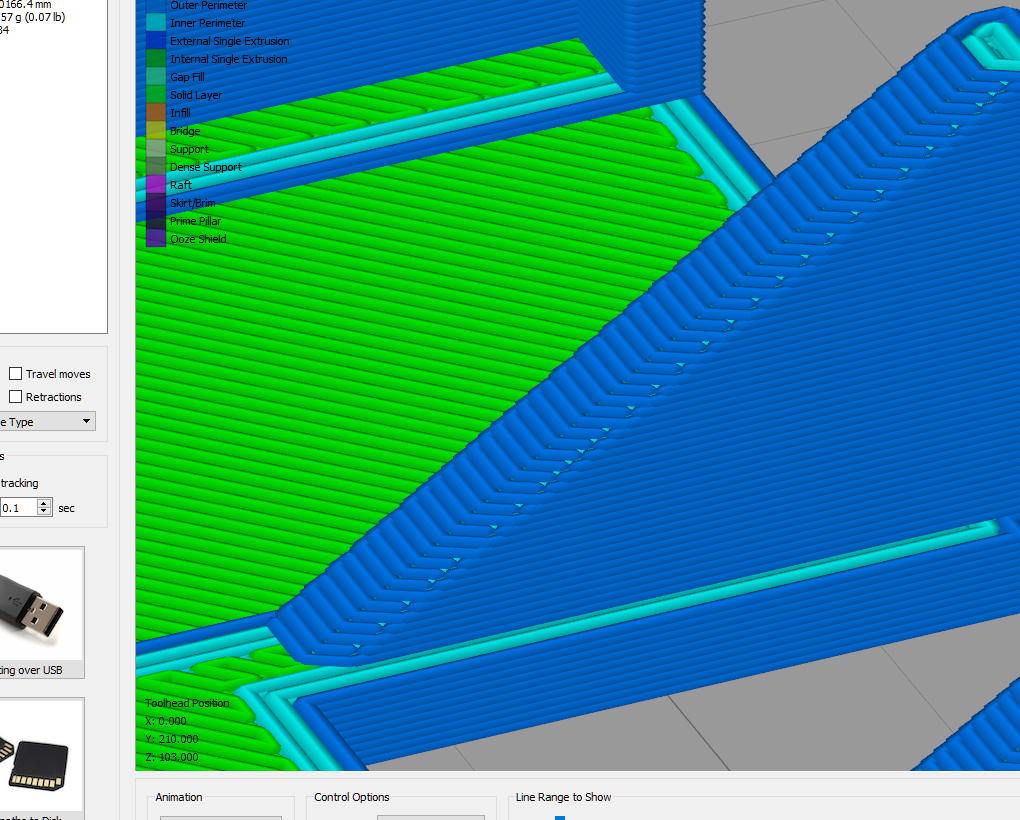

1-those look like start/restart artifacts, which are normal depending on if you have coasting enabled and your retraction settings. in simplify3d (maybe others too) they're actually visible in the gcode preview if you look closely

2-normal. its called ghosting. the solution is to slow down the whole print, or at the very least turn down you perimeter print speed in your slicer.

Re: Print quality question

Thanks for the dropbox tip - I fixed my original post and this is good information to know.

I will adjust the external perimeter speed and see how that helps with ghosting.

But regarding start/restart artifacts, I changed the Seam Position to Aligned and have a worst mess - see pics below. Now the mess is all on one outside corner and the other corners are beautiful. But I still need to fix the problem. Back before I had the MK3, I used generic Slic3r and never had this problem. So I'm guessing that it's a problem with the factory settings coming from Slic3r PE. Any idea how to fix it?

Also an additional clue. The object I'm printing is hollow, and has a 1.5mm exterior surface all around. The very bottom layers , where the bottom surface is full and not hollow (not just 1.5mm of perimeters), and the very top layers (same condition) do not exhibit the messy corner - the corner at the very top and bottom there is fine.

Re: Print quality question

I would start by checking the printer.

Is the belt pressure correct? (Support / Belt status)

Rotates X- and Y- axis end pulleys easily. If not, loosen the center screw slightly.

The default settings in Slic3r are good enough to get flawless prints.

Bear MK3 with Bondtech extruder

Re: Print quality question

I've checked and the printer itself seems fine. Both axis move fine, belt tension is good.

Everything else about the prints is excellent including the other 3 corners.

I'm guessing this is a Slic3r PE issue - perhaps a setting when it moves up one layer. Almost like it retracts the filament (which is should), goes to the next layer starting point, and either doesn't "unretract" or move enough filament so that the next layer extrusion starts out empty. That's kind of the symptom I'm seeing. Except that using factory Slic3r PE settings it shouldn't be an issue.

Re: Print quality question

Additional Information: I just tried slicing with the MK2 version of Slic3r PE and I do not get the mess at the corner that I did on the original print. There is a slight imperfection at the same corner, but nothing like the original. Note that I've tried some different things with the Slic3r PE MK3 version (other temps, add some unretract) and they all generate the same mess in the corner.

This doesn't make much sense, since the software is the same. The only thing different (other than an additional instruction for the ending GCODE) I can find is the printer definition and all I see different is the M115 GCODE instruction which tell the printer which firmware version to expect.

Help?

Re: Print quality question

ira,

which version of the firmware are you using. There recently was a fix for extruding small layer heights which fixed mess like in your "align start seam positions" pic.

Re: Print quality question

Hi Ira

Are you using the latest firmware and drivers /slicer?

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print quality question

I am seeing a similar issue showing up in my prints and was just trying to think of the best approach to correct this. Using the most recent firmware 3.1.3 and slicing through the slic3r PE ver: 1.39.1. I would like to upgrade to a ruby nozzle at some point but I rather fix the current flaws and problems before I replace the nozzle and chase my tail on items unrelated.

[attachment=1]IMG_0695[1].JPG[/attachment]

As for this one I am not sure its part of the problem but its something Id also like to try and figure out the best route to correct. Last time I thought it was a cooling issue for another print I had and support had me update the firmware and it corrected the issue but now I am again seeing what I believe could be a cooling issue but I am unsure of a proper solution.

[attachment=0]IMG_0694[1].JPG[/attachment]

Re: Print quality question

Thanks for the dropbox tip - I fixed my original post and this is good information to know.

I will adjust the external perimeter speed and see how that helps with ghosting.

But regarding start/restart artifacts, I changed the Seam Position to Aligned and have a worst mess - see pics below. Now the mess is all on one outside corner and the other corners are beautiful. But I still need to fix the problem. Back before I had the MK3, I used generic Slic3r and never had this problem. So I'm guessing that it's a problem with the factory settings coming from Slic3r PE. Any idea how to fix it?

Also an additional clue. The object I'm printing is hollow, and has a 1.5mm exterior surface all around. The very bottom layers , where the bottom surface is full and not hollow (not just 1.5mm of perimeters), and the very top layers (same condition) do not exhibit the messy corner - the corner at the very top and bottom there is fine.

Okay so in the process of fixing my overhang/cooling issue I think I fixed that surface issue you was seeing. What I did was go to layers and perimeters at the very bottom in the advanced section that has seam position and the external perimeters first I checked the box for external perimeters first and as far as I can tell removed those flaws from the surface. I only spotted a couple little spots on the first couple layers but the rest of the one print I did seems to be clean.

Re: Print quality question

The default settings in Slic3r are good enough to get flawless prints.

I've been wondering about this as I muck with slic3r settings to improve my quality. I have several issues, but the one I started working on first was the quality of seams in the print surface. I noticed when using slic3r to print a standard xyz calibration cube I'd get some raised horizontal lines in the corners that I later determined where happening at the start/end of the outer perimeter (the location of these lines was very repeatable). I see the exact same defects in other calibration cubes that I see posted here and I assume those people are also using the default slic3r settings (Prusa PLA, Fast .2 mm layer height)

I got those to look better using Cura, but I am really curious to see what the same cube looked like with the default slic3r settings looks like on your printer. If you haven't printed one and are super bored one day maybe you could print this object in the gray prusa pla with default .2 mm slic3r settings and post some pictures. 😀 Here are some pictures of mine that show the issues I've seen.

Re: Print quality question

I am seeing a similar issue showing up in my prints and was just trying to think of the best approach to correct this. Using the most recent firmware 3.1.3 and slicing through the slic3r PE ver: 1.39.1. I would like to upgrade to a ruby nozzle at some point but I rather fix the current flaws and problems before I replace the nozzle and chase my tail on items unrelated.

IMG_0695[1].JPG

As for this one I am not sure its part of the problem but its something Id also like to try and figure out the best route to correct. Last time I thought it was a cooling issue for another print I had and support had me update the firmware and it corrected the issue but now I am again seeing what I believe could be a cooling issue but I am unsure of a proper solution.

IMG_0694[1].JPG

Hi Ben.

Looks like you are printing a torque spanner for nozzle fitting.

On mine. The underside of the vanes was a bit like yours.

I slowed the print down and inceased the cooling on the PETG Profile

I wanted to keep bigger layer height and higher temperature in order to maintain strength and inter layer bonding

Regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print quality question

I am seeing a similar issue showing up in my prints and was just trying to think of the best approach to correct this. Using the most recent firmware 3.1.3 and slicing through the slic3r PE ver: 1.39.1. I would like to upgrade to a ruby nozzle at some point but I rather fix the current flaws and problems before I replace the nozzle and chase my tail on items unrelated.

IMG_0695[1].JPG

As for this one I am not sure its part of the problem but its something Id also like to try and figure out the best route to correct. Last time I thought it was a cooling issue for another print I had and support had me update the firmware and it corrected the issue but now I am again seeing what I believe could be a cooling issue but I am unsure of a proper solution.

IMG_0694[1].JPG

Hi Ben.

Looks like you are printing a torque spanner for nozzle fitting.

On mine. The underside of the vanes was a bit like yours.

I slowed the print down and inceased the cooling on the PETG Profile

I wanted to keep bigger layer height and higher temperature in order to maintain strength and inter layer bonding

Regards joan

yea I'm trying the torque and I'm about the point of trying to start slowing it down to correct the problem. Right now I'm just printing it in pla and as far as I can tell the fan option is maxed out. I done a few other prints that have some overhang and seen similar results and I'm just chasing getting the print dialed in. I just hate to go to the point of having to touch speed as I done bigger prints that have a small section that has overhang and I hate to impact the print as a whole for a small overhang.

Re: Print quality question

Hi Ben

I think you just hit the nail on the head.

PLA Is more rigid than PETG.

I did mine in PETG...

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Print quality question

The default settings in Slic3r are good enough to get flawless prints.

I've been wondering about this as I muck with slic3r settings to improve my quality. I have several issues, but the one I started working on first was the quality of seams in the print surface. I noticed when using slic3r to print a standard xyz calibration cube I'd get some raised horizontal lines in the corners that I later determined where happening at the start/end of the outer perimeter (the location of these lines was very repeatable). I see the exact same defects in other calibration cubes that I see posted here and I assume those people are also using the default slic3r settings (Prusa PLA, Fast .2 mm layer height)

I got those to look better using Cura, but I am really curious to see what the same cube looked like with the default slic3r settings looks like on your printer. If you haven't printed one and are super bored one day maybe you could print this object in the gray prusa pla with default .2 mm slic3r settings and post some pictures. 😀 Here are some pictures of mine that show the issues I've seen.

https://www.thingiverse.com/thing:1278865

This is what I got for the cube using basically the same settings as you. not completely perfect but I will work on that later once I get my overhang problems fixed.

[attachment=0]IMG_0698[1].JPG[/attachment][attachment=1]IMG_0696[1].JPG[/attachment][attachment=2]IMG_0697[1].JPG[/attachment]

Re: Print quality question

The default settings in Slic3r are good enough to get flawless prints.

This is what I got for the cube using basically the same settings as you. not completely perfect but I will work on that later once I get my overhang problems fixed.

Looks like you have the same issues in the corners that I do. The reason you don't see those in the middle of the edge is because in the default profiles the slicer is putting the seams on the internal edges of the embossed letters, which hides them. I changed to put the seam in the back and the corners looked much, much better. It isn't a long term solution, but at least gives me something targeted to focus on.