PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

I made a print with Colorfabb XT.

Colorfabb XT:

The printer was brand new (assembled by prusa), I did not prepare the steel sheet and it was not dirty or anything like that.

The material I printed literally glued itself to the PEI sticker foil. It could_not_be_removed from the steel sheet after the print.

I couldn´t even pull off the parts by force.

Trying to grab a part with the pliers and applying all force I had in my hand to remove it only damaged the printed parts and lifted the whole printer from the table!

In the pictures I attach I explicitly tried to avoit any contact of my removal tools with the pei sticker sheet. I did not want to damage the sheet. It was really difficult. Look at the pictures how my sheet looks after removal...

And here some seconds of my removal action as youtube video...

My feeling is this:

Prusa did not inform me that I cannot use this material to print on the steel sheet. I used the Prusa Slic3r MK3 software which has a profile for Colorfabb XT. So how should I know that this is not intended use when I am using a Prusa MK3 printer out of the box and then using the Colorfabb XT material?

Support says:

Wrong use of mine, I could have done many things wrong, the sheet was maybe dirty, I damaged the foil with my tools blabla..

They say I should have taken the sheet of the printer and bended it (which I did, no chance for anything to come of, the part broke on the bended area, still sticking to the sheet).

They did not accept that it is missing communication of Prusa´s side to inform the customers to not use certain materials.

I asked for a replacement or a reduced price to reorder a sheet, and am still waiting for the support manager escalation since almost 4 weeks.

Ngen:

I now startet printing Ngen parts using the other side of the sheet, and realised that on the area where the parts are printed the foil throws tiny bubbles, and the parts leave an impression where they where. (Like with old CRT monitors, where images could burn in that you showed on the monitor for a long time)

Parts come off easy, but when I move my finger over the area where a part has been printed on, I can feel an unevenness with my finger.

So long story short, it appears to me that also Ngen is not meant to print on the PEI sticker foil.

PLA prints perfect, comes off perfect, no problems there.

Why don´t you tell us this on the product page Prusa? ❓ 😕

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Hello Daniel,

To my experience, some Flex, TPU or sometime PETG filament could stick very strong to the PEI spring sheet.

Due to the flexible properties of the material, you couldn't use the bending of the sheet, the part bend also...

What I do to decrease the aderence :

1) clean the bed spring sheet with isopropyl alcool,

2) put a thin layer of the glue stick you receive with the printer, on the print surface (not all the surface, it's not usefull),

3) quickly before the glue dry, I use a useless credit card (one in good shape, sharp edges) to spread out and smooth the glue layer,

4) let the printer preheat (bed and extruder),

5) Before starting the print and when the glue is dry, use a clean paper tower to smooth (and eliminate blobs of the glue) the print area.

(Don't press too much, just to tickle the layer...).

6) print...

7) normally the parts should be removed quite easily, use a spatula to lift off a corner of your part and put the spatula under the part carefully.

This procedure work good for me, I hope for you too !

😉

EDIT:

After removing the parts, I clean the glue on the bed sheet with lukewarm water, dish soap and a sponge.

Dry it with a dish towel.

Ready for the next print according the procedure above !!!

Note: I read that with Windex you can also resolve the case, but never tried...

Ludovic

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Did you see the materials guide in the Printing Handbook?

Colorfabb XT is a PET variant, if I’m not mistaken...

I know the handbook says something about PET products sticking too well, especially if you use IPA to clean the bed. It says to use Windex, or glue stick as a release agent.

When someone asks you if you're a god, you say, "YES!"

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

When i try new Filament that is kind of "special", i normally use some gluestick, tape or windex as seperator.

Just in case.

But first of all i read the manual or product desription.

Sometimes it´s surprising me with important information. 😉

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

@Ludovic.D

Thank you for these tips!

I will try to do that if I need to. For now I only use PLA. I withdrew from printing Colorfabb XT at all.

I am waiting for the powdered metal sheet to become available from Prusa to use for these kind of materials.

@joe.m14, kai.r3

I read the manual.

6.3.2 ff in the Handbook:

It says nothing about not printing with these materials on the Flexible steel sheet surface.

It only says: Isopropyl alcohol may not be good enough to clean off PETG from the surface when you clean your sheet.

It does not say: These materials will stick so hard to your Flexible steel sheet, that the coating of the sheet comes off rather than your printed part.

Should not need trial and error by end users for this.

How many users may have damaged their sheet like me?

The company and also the support must know about this, they make thousands of printers.

And also if this is so significant, it should not only be mentioned on some deep page in the handbook. It should be a little sentence on the product page like:

These materials support direct printing on the surface: PLA, xxx, yyy

These materials should NOT be printed directly on the sheet. The sheet should be prepared before, or use another sheet: Colorfabb XT, Ngen, zzz

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

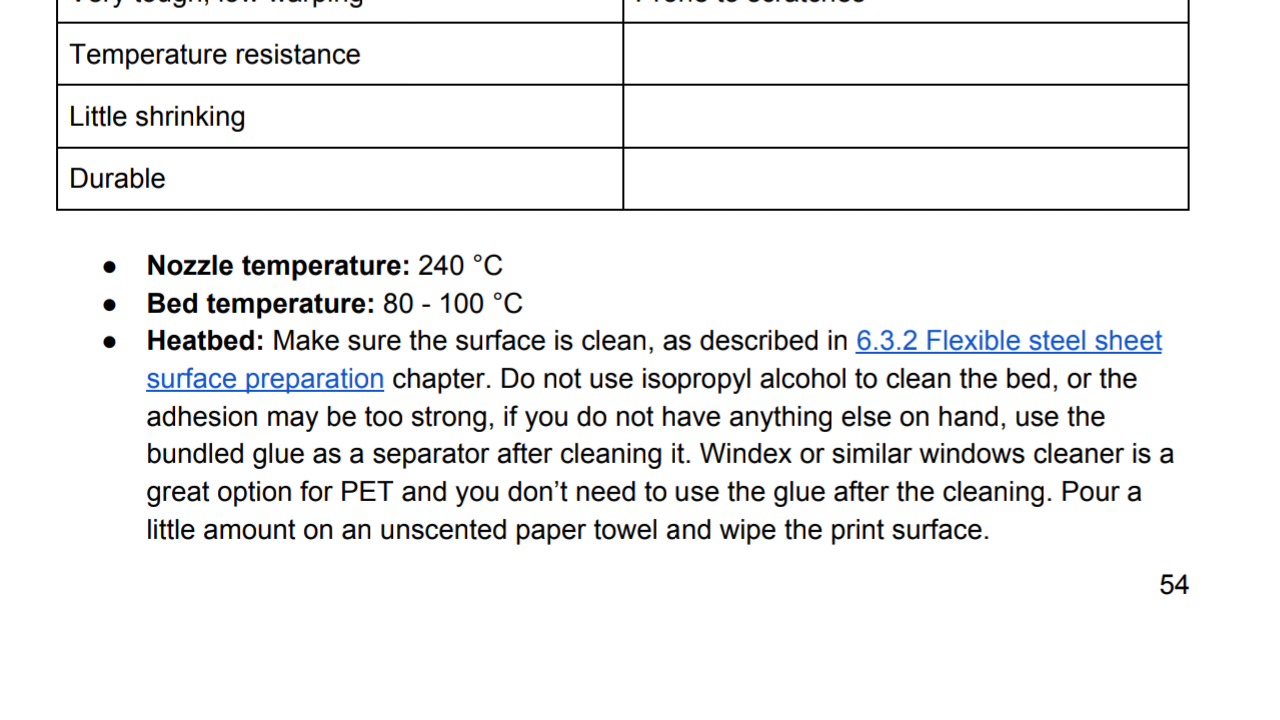

From Section 11.3 PET/PETG of the User manual:

● Heatbed: Make sure the surface is clean, as described in 6.3.2 Flexible steel sheet

surface preparation chapter. Do not use isopropyl alcohol to clean the bed, or the

adhesion may be too strong, if you do not have anything else on hand, use the

bundled glue as a separator after cleaning it. Windex or similar windows cleaner is a

great option for PET and you don’t need to use the glue after the cleaning. Pour a

little amount on an unscented paper towel and wipe the print surface.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

I print regularly with colorfabb_XT (regular and cf) and Ngen on my MK3 and never had any serious issues with adhesion.

Parts do tend to stick quite well to it, but have never fused themselves to the sheet as in your pictures.

I found that the z-offset needs to be a little bit higher than with PLA... you don't want to have much "squish" at all with these materials on your first layer. Also, since those are all PET-based filaments, a little glue stick goes a long way to facilitate removing the part.

The only instance in which It was a bit of a pain to remove a XT part was when I printed it @ 0.05mm layer height.

Finally, and this may be just me and may not be good advice at all, I don't clean my bed very often. After wiping it down with IPA the adhesion is too strong for my liking.. I only quickly wipe it down and let it sit at 70C for 5 minutes every 10-15 print. It might be superstition, but it does and has worked for me on all my printers, and I use PEI as a surface on all of them.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Dear, exactly same issue for me with Colorfab XT and Prusa ABS filaments in my new Pursa i3 MK3 printer, I see some ideas in the topic to deal with (Lodovic.D) but hope we get a final answer coming out from Prusa.

If anyone know something new about It will be great if shared here, bets

Samuel

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

What answer to what question?

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Ok, its clear now that some of these materials should not be printed on the PEI foil directly.

Maybe I had a especially strong adhesion because my filament was already some months old, I don´t know if that adds to it.

I think that "warning" / information from Section 11.3 is really deeply hidden in the manual, and it is really weak compared to the seriousness of the problem.

😯 It´s like I have a door in a room of my appartement on the 20th floor of a building with a little sign saying "Please be careful when entering" and then behind the door there is directly the abyss!

Guests walking around in my Appartement at night looking for the toilet sometimes just fall off the building... 🙁

😮 Oh didn´t you read the sign in the dark saying be careful?

I have never cleaned my surface yet other than wiping it with a dry microfiber towel. I don´t really like to put glue stick on my plate.

I hope the replacement sheets will be available in the different materials as soon as possible from prusa.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Ok, its clear now that some of these materials should not be printed on the PEI foil directly.

It's been clear all along. Just because you don't read the materials portion of the manual doesn't make you a discoverer when you find out what is already in the manual.

I think that "warning" / information from Section 11.3 is really deeply hidden in the manual, and it is really weak compared to the seriousness of the problem.

Well it is right in the middle of the materials chapter, not hidden

. Then use windex like the manual suggests. Although frankly I cannot imagine why you wouldn't want to use gluestick

I don´t really like to put glue stick on my plate

I hope the replacement sheets will be available in the different materials as soon as possible from prusa.

All the sheets will be pei of one sort or another. But the textured sheet will grip even harder since the texture will have much more than surface area for the same size model.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Coffe mug - caution hot!

Microwave oven - do not dry wet pets in it!

It is so American (no offense!) to cover your ass and write the most obvious warnings everywhere.

Real talk: Read the f&§&/§ing manual!

Edit: And just buy a replacement PEI sticker for 8 bucks and learn from your mistakes

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

I have found that authentic Windex (regular formula, nothing special) is not enough for some PETG, depending on the temperature you are printing at. I have some Filamentum PETG (their CPE HG 100) that prints at 270. I don't dare print this without glue stick.... Windex is just not enough of a pre-coating.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

All the sheets will be pei of one sort or another. But the textured sheet will grip even harder since the texture will have much more than surface area for the same size model.

I have the MK2S printer as well. I printed the Colorfabb XT, the ngen and several other Filaments on this printer using the default print bed. On that printer it is no problem at all.

I assumed now the problem is tied to the flexible steel sheet especially. So I also assume that other sheets will again behave like I am used to it from the MK2S.

It's been clear all along. Just because you don't read the materials portion of the manual doesn't make you a discoverer when you find out what is already in the manual.

Please quote to me the exact phrase of the manual that unmistakenly explains the situation that I encountered when you check my photos and my video in the initial post.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

I print PETG on my MK2s without any release agent. maybe my sheet needs some light sanding. (99.9% IPA or acetone doesn't make it stick any harder either). maybe the PEI on the steel sheet is better or it's just a case of being new.

i think with 100's if filament brands it can be hard to list everything in the manual. A warning of sticking too hard could be put there but it depends on your Z height too.

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

I have found that authentic Windex (regular formula, nothing special) is not enough for some PETG, depending on the temperature you are printing at. I have some Filamentum PETG (their CPE HG 100) that prints at 270. I don't dare print this without glue stick.... Windex is just not enough of a pre-coating.

I use in Germany https://www.amazon.de/Ajax-Glasreiniger-3-fach-aktiv-500ml/dp/B001QGUN0O (nearly every local store has it). For every print first cleaning with IPA, then the window cleaner (checking that the entire sheet is a little bit wet). After it is dry, use a second time the window cleaner. I print nothing else than PET (Innofil3d innoPET, Colorfabb NGEN, Fillamentum CPE, ESUN PETG, DasFilament PETG). Never had a problem with too sticking parts. Only if I use the window cleaner for a third or forth time, it can happen that the first layer does not stick at the sheet (thats why the "Reset" with IPA).

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

When i try new Filament that is kind of "special", i normally use some gluestick, tape or windex as seperator.

Just in case.

But first of all i read the manual or product desription.

Sometimes it´s surprising me with important information. 😉

I've heard of using these different chemicals in all my readings of the forum, but is there any guide to how much and which you use for each filament? I'm still new to 3D printing and waiting for a part that broke so I can finish my build.

When is it best to use

1. Tape "Blue Masking" correct?

2. Windex

3. Gluestick

a) Do you just smear it on like crayon to paper?

Thank you for putting up with us newbies

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Coffe mug - caution hot!

Microwave oven - do not dry wet pets in it!

...

3D printer - Do not use it!

....

There are so many things you can do wrong with it 🙂

I'm printing Makergeeks PETG and Maker Flex (TPEE) without any issues on my MK2 PEI sheet.

Just raise a z-height a little bit (DON'T SQUISH IT) and use Windex. Parts are coming off really easy without damaging anything.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: PEI Steel sheet problems - not suitable for (some) non PLA materials - Colorfabb XT, Ngen

Coffe mug - caution hot!

Microwave oven - do not dry wet pets in it!

...

3D printer - Do not use it!

....

There are so many things you can do wrong with it 🙂

I'm printing Makergeeks PETG and Maker Flex (TPEE) without any issues on my MK2 PEI sheet.

Just raise a z-height a little bit (DON'T SQUISH IT) and use Windex. Parts are coming off really easy without damaging anything.

Same, except I don't use windex. I do clean it with IPA before every print, but I make sure its not too close for the first layer. I have been printing flex quite regularly on my mk3 for the past 2 weeks. I have a local drone flyer that loves NinjaFlex. It comes off quite easily with a healthy dose of IPA directly onto the part and sheet.

Here is my video on it: