New user issues

Hello,

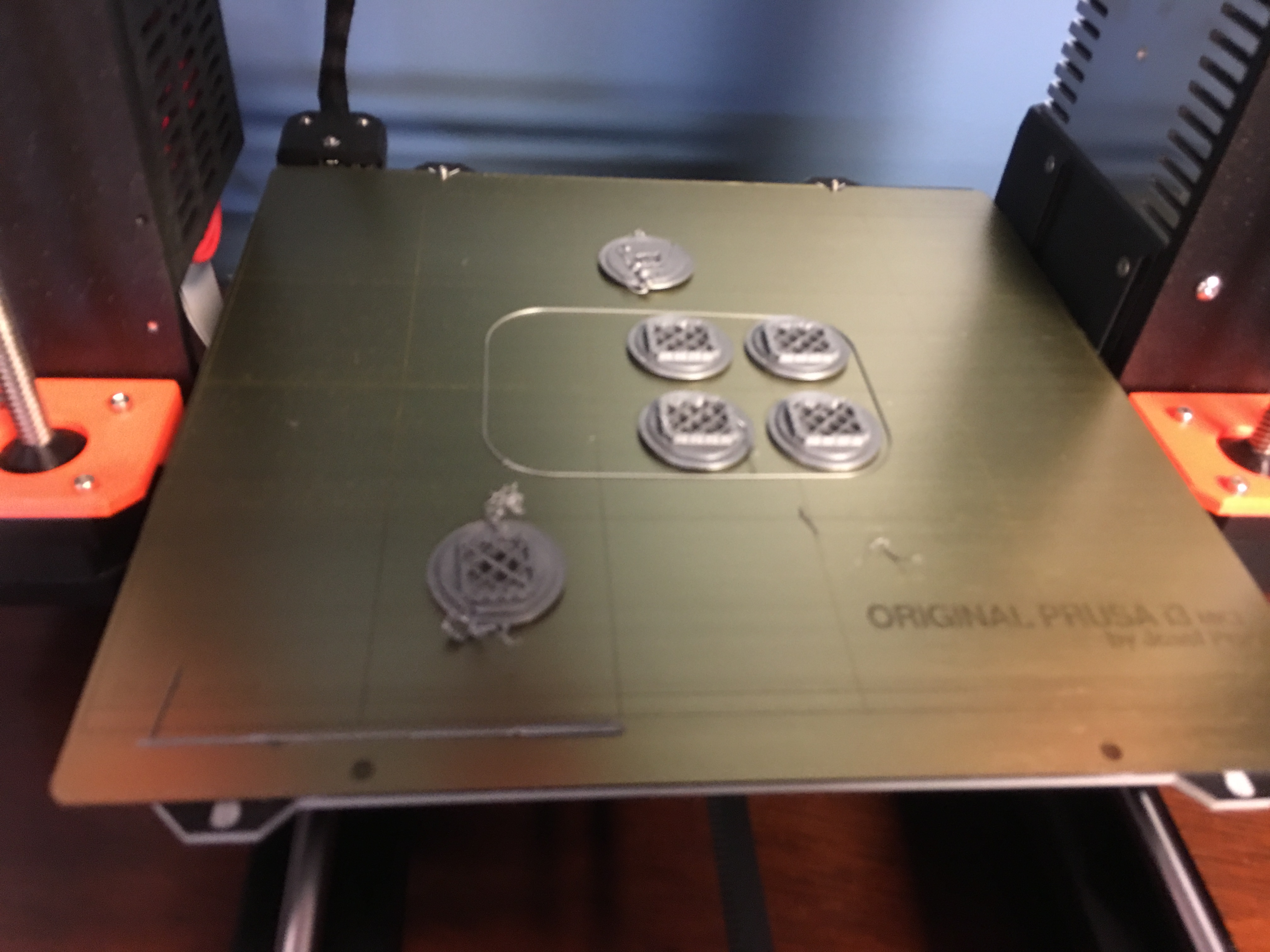

Hoping I can get some help with my new printer. I’m a new user. I just started printing yesterday and had one successful print then two with problems as outlined in the pictures. Basically the prints are found moved and have stringy bits all over them and the nozzle is covered in plastic. I have not caught this in action as it appears to work ok but then this happens over an hour in each time.

Of note I’m using a unit built by Prusa, performed the z calibration, confirmed the bed is clean, using Prusa PLA, files in gcode from Prusa slic3r, and have tried .10, .15, and .20 with the same results.

Re: New user issues

Have you performed the "First Layer Calibration" (live Z)?

If you have not, I would guess that your first layer is WAYY too high.

Could you send a picture of the little square at the end of the "First Layer Calibration".

Also, if you would rather, have your printer print the first layer of something, and then stop the print.

To me, this looks like bad layer adhesion.

Here's a step by step blow of what I think is happening.

1. Nozzle is too high from the heat bed, and not "sticking" the filament to it properly. This creates a loose bond, that easily pulls up.

2. As the parts pull up/move/neverstuckinthefirstplace, the nozzle will continue to extrude filament into the air, not connected to anyting, this creates the effect that you see.

3. If you were to continue to let it print for another hour or so you would have one giant solid blob of plastic wrapped around your nozzle! (This is bad)

Check your handbook for "First Layer Calibration".

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: New user issues

Thanks Sean. I will try this. I had not previously done this as I believe it is done at the factory from Prusa for the pre assembled kits (as calibrate z is the only calibration instruction under the pre assembled.)

Re: New user issues

Thanks Sean. I will try this. I had not previously done this as I believe it is done at the factory from Prusa for the pre assembled kits (as calibrate z is the only calibration instruction under the pre assembled.)

Not sure about the instructions, but I do a Live Z every time I change filament. 😉

It's a pain in the rear, but, you start a 12 hr print, and go to bed... or work... or anything that takes more than an hour... and you come back and your nozzle is a solid block of plastic.

Yup. The 2 minutes spent doing the Live Z is worth it. 🙂

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: New user issues

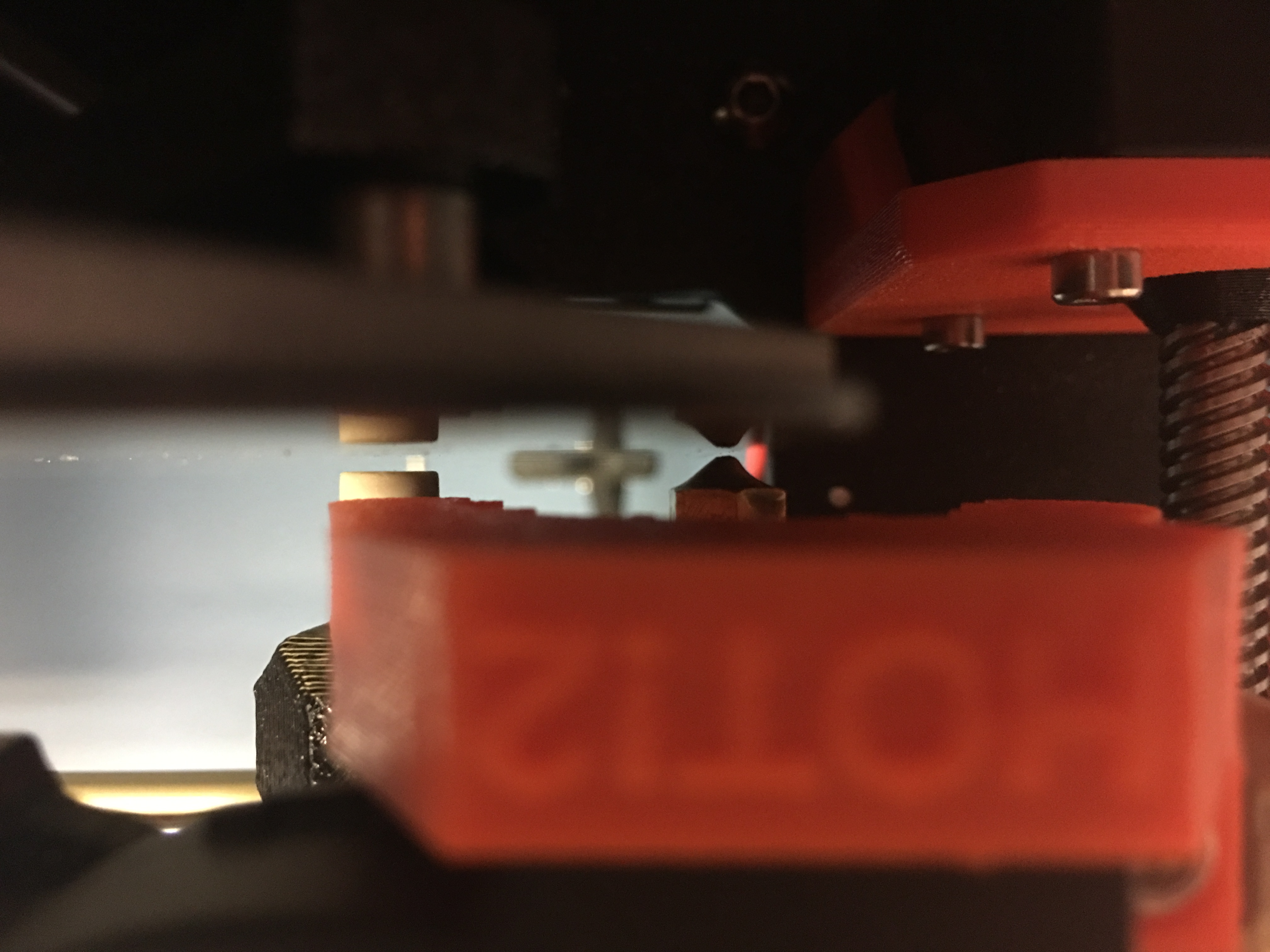

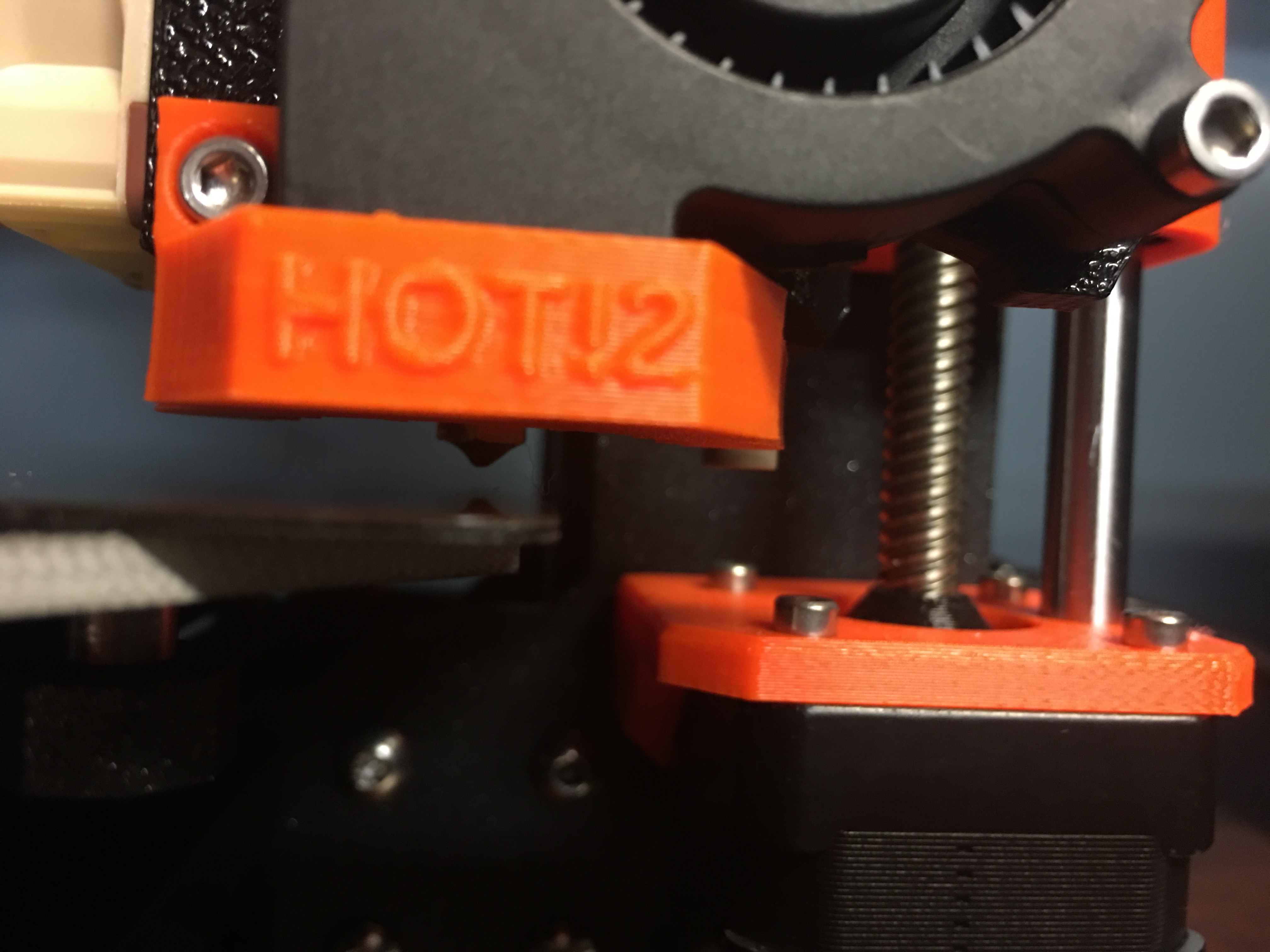

WAY too high. Looks almost .25 to.5mm too high.

(you need a bigger negative number)

This is 100% your problem.

You may need to adjust your PINDA probe a touch, as I would almost think it's too close to the print bed with numbers like that.

http://manual.prusa3d.com/Guide/9.+Preflight+check/514?lang=en <--- instructions on how to adjust PINDA height.

You want your live adjust between -0.5 and -1.0 (with -1.0 actually being a bit low) You are already at -0.88, which is right around where it should be.

Typically there is no harm in brining that number to -1.2, but I say typically, as that's putting the PINDA *really* close to the stuff you just printed. I agree, this should have been caught at the factory, this is an assembly mistake.

EDIT: I'm not sure if your printer came the zip ties. They are 1.2mm thick.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: New user issues

No zip ties here. But I used on I had on hand. I scuffed the heat bed slightly too :/

Regardless there is no notable change. Here’s -.900. Pretty frustrating. This is why I paid $250 for the pre assembled! Thanks for the effort though.

Re: New user issues

No zip ties here. But I used on I had on hand. I scuffed the heat bed slightly too :/

Regardless there is no notable change. Here’s -.900. Pretty frustrating. This is why I paid $250 for the pre assembled! Thanks for the effort though.

image.jpg

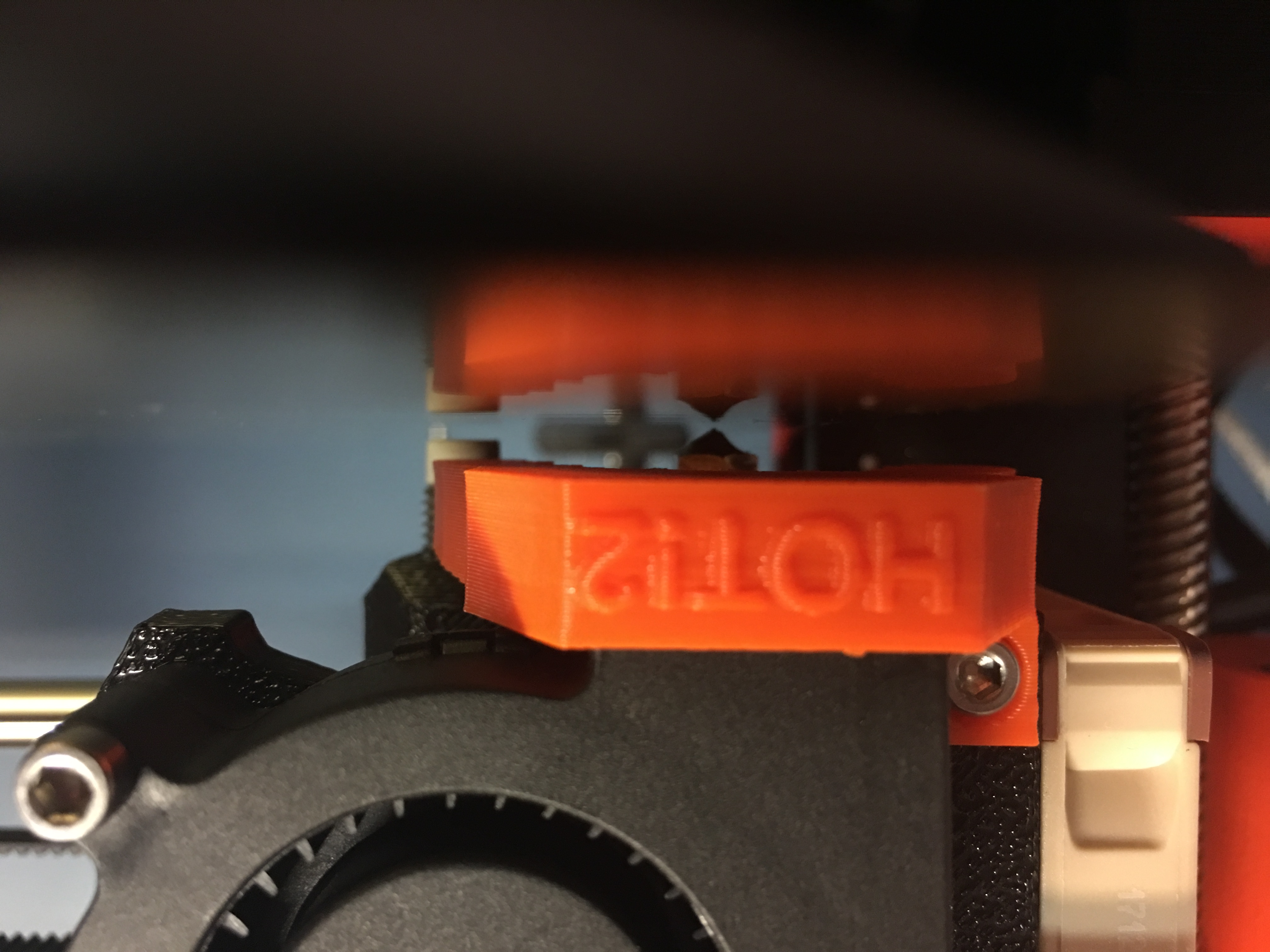

Here’s my z axis bottomed out. Appears like the probe is quite crooked too. (It was this way before my adjustments)

Re: New user issues

Move your Z all the way to the top, both sides should hit the top braces at the same time. If they don't then you need to re-run the xyz calibration because your two z motors are slightly off from each other.

Re: New user issues

Move your Z all the way to the top, both sides should hit the top braces at the same time. If they don't then you need to re-run the xyz calibration because your two z motors are slightly off from each other.

Tried this and they appear even. It doesn’t let me physically top out though, at least on anything I can see. But they hit a stop together.

Re: New user issues

Move your Z all the way to the top, both sides should hit the top braces at the same time. If they don't then you need to re-run the xyz calibration because your two z motors are slightly off from each other.

You do not need to move Z manually.

Make a Z calibration in the Calibration / Calibrate Z menu.

Bear MK3 with Bondtech extruder

Re: New user issues

Move your Z all the way to the top, both sides should hit the top braces at the same time. If they don't then you need to re-run the xyz calibration because your two z motors are slightly off from each other.

You do not need to move Z manually.

Make a Z calibration in the Calibration / Calibrate Z menu.

I did the Z calibration right out of the box. And the XYZ again yesterday. At -1.1mm I felt like I was getting closer to a good pattern but the book says to stop at -1. Once I noticed the probe was uneven and that the bed leveling was off I wasn’t comfortable moving the probe yet. I want to see what official support advises. It’s possible there’s a hardware defect or assembly error

Re: New user issues

I also bought a pre-built printer, but the calibration was a bit sloppy. At the XYZ calibration, the nozzle scraped into the bed.

I unscrewed the Pinda sensor slightly and screwed it down half a turn. After that, the calibration worked and now Z-level is at -550.

In your case, you would need to screw the Pinda sensor up half a turn to get a value below -1.

I do not think it's a hardware issue. It is a calibration problem that you have to fix yourself.

Check this video.

https://shop.prusa3d.com/forum/original-prusa-i3-mk3-f30/the-most-important-links-original-prusa-i3-mk3-t13545.html

Bear MK3 with Bondtech extruder

Re: New user issues

I too have received an assembled MK3 printer. I went through all the calibrations and the menu first thing before printing then used the calibration square for the MK2S. I think the act of securing the machine with zip ties prior to shipping is knocking off the factory settings before shipping. Add to that the act of shipping and the amount of vibration, knocks, bumps, and what not encountered on its trip and you may as well consider it out of calibration anyway.

Neal

Re: New user issues

No zip ties here. But I used on I had on hand. I scuffed the heat bed slightly too :/

Regardless there is no notable change. Here’s -.900. Pretty frustrating. This is why I paid $250 for the pre assembled! Thanks for the effort though.

image.jpg

Your printer is assembled which is what you paid for. You are always going to have to tweak, modify, and tune in. It is all part of the hobby. Maybe 3D printing isn't for you if you are not willing to do that.

Re: New user issues

Sensor pinda white? ... mine is black, how strange

Re: New user issues

Sensor pinda white? ... mine is black, how strange

I noticed they were black in the assembly pictures. Didn’t think much of it though.

Re: New user issues

It´s a poor assembly job. I am sorry for you there.

Selling any electronic item as finished products normally requires the manufacturer to take responsibility for the functionality of his product. I don´t see the responsibility on the users side here.

Your printer is assembled which is what you paid for. You are always going to have to tweak, modify, and tune in. It is all part of the hobby. Maybe 3D printing isn't for you if you are not willing to do that.

In some Youtube Video I saw Prusa saying that he wanted to make 3D printing available to newbies and users without significant time and background knowlege to enjoy 3D printing out of the box. This is kind of not achieved in this case.

So no, when you order the assembled version it should not be on the user to be responsible to tweak and readjust and fiddle all kinds of things to get it running. Problem for the newbie is he also does not know all these many factors playing a role in successful 3D printing.

When I buy a Canon or HP paper printer (assembled) it also works, because they did their homework.

I´m glad that my printer works like a charm.

Re: New user issues

they have commented to me from support that a remittance had the white cap, but the sensor is identical