MK3 - Problem with ABS - Failed print[s]

Hello all.

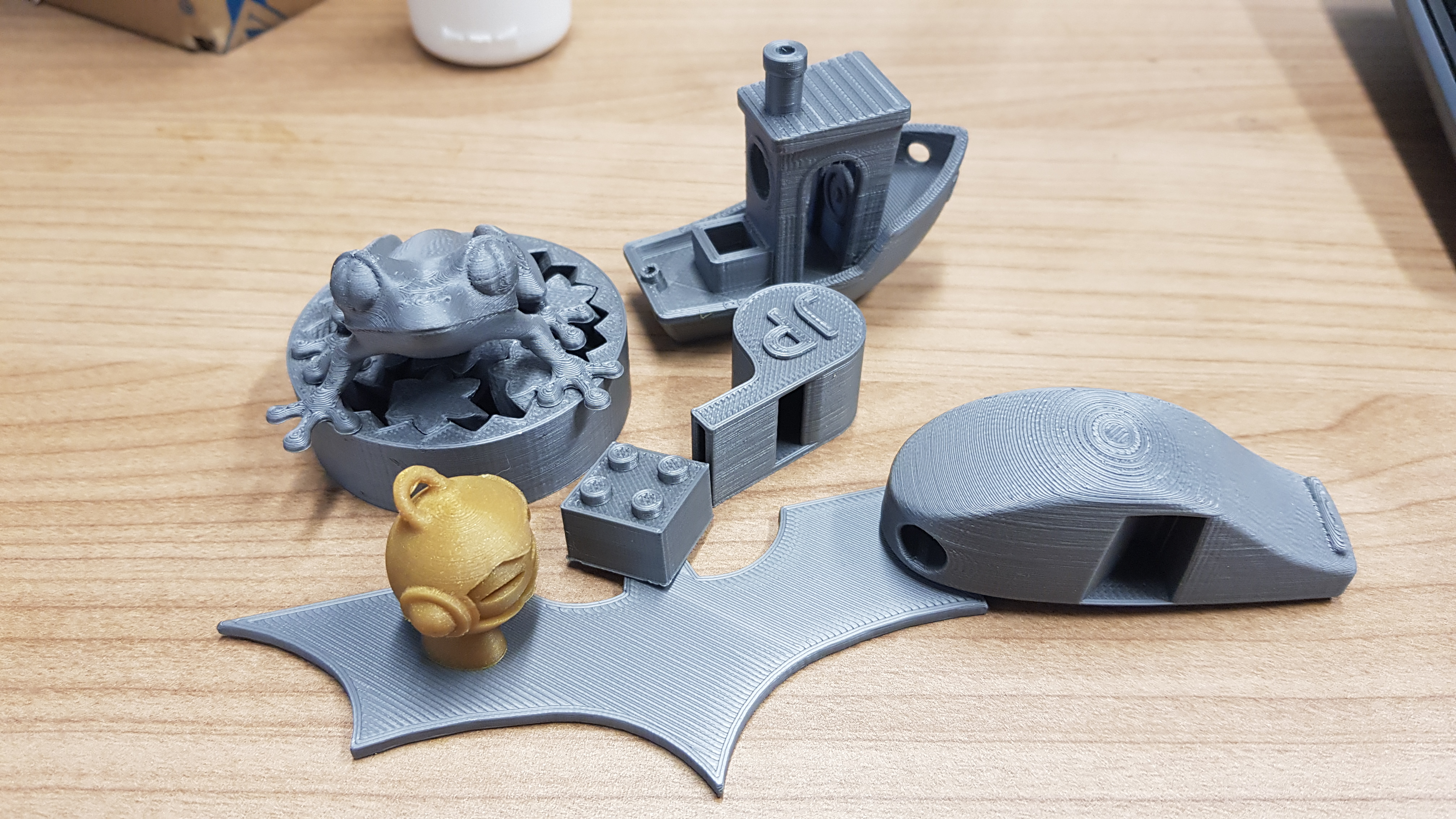

Prusa i3 MK3 is my first 3d printer, and overall I'm really happy. GREAT JOB! I had many successful prints in PLA with no issues [photo1]. But when I tried with ABS... results look right straight from the horror movie 😉 [photo2]

At this point I have no idea what to check next. Can you please help me?

Re: MK3 - Problem with ABS - Failed print[s]

Disclaimer: I neither own a MK3 (yet) nor do I have that particular Brand of ABS.

This still looks at least partially to be a temperature issue, by how much did you try reducing the temperature?

The shop states 220-240° for this Filament and I just checked Slic3r PE with Generic ABS Settings, and it sets the Temp to 255 by default, which seems seems way too high then.

Re: MK3 - Problem with ABS - Failed print[s]

I don't remember correctly, but I decreased it at least to 240. You think I should try lower? Like 220?

I changed the temperature on the printer, not in the slicer. Is there any difference?

Re: MK3 - Problem with ABS - Failed print[s]

The only difference would be that doing it in your slicer and saving to disk means all your models will be printed using what ever is recorded on the disk. BUT you can fidget with those temps and some other settings "on the fly" with the printer itself. Those "on the fly" changes will be used during the print until you manually change them. They will NOT be saved as changes on your disk.

Best is what you are doing now. Print from disk at recommended settings. Use small quickish prints so you can watch them and see what is happening. Tweak (change on the fly) your temp settings until you get it to where you want it. And remember that one of the handiest tools at your disposal is a pad of paper and a pencil to keep track of your changes.

There are a lot of other variables to take into account but you can see that from all the posts in the forum. Take it in small increments and you will usually see better results as you go forward.

Hope that helps,

Neal

Re: MK3 - Problem with ABS - Failed print[s]

another difference between ABS and PLA (besides temperatures) is the use of the parts cooling fan. Maybe Easy ABS could would prefer some cooling (in Slic3r the parts cooling fan is only used for bridges with ABS)

Re: MK3 - Problem with ABS - Failed print[s]

I have a MK2S and tried printing ABS for the first time (lots of PLA printing, but no ABS before this).

I had to reduce the temp down to 230C to get decent prints. Anything much above that (240C or more) caused very poor prints, and much below that (220C) caused adhesion problems.

The default from Prusa is 255C in the printer itself (preheat) and Slic3r PE. I guess that's the correct setting for ABS purchased from them - they have to know what's best.

But that also tells me that there must be a lot of variation in ABS filament from one vendor to the next. Otherwise, why would 255C be (presumably) so good for their filament and so bad for another vendor's ABS.

I'd appreciate info from anyone who'd like to chime in. Is my 230C experience an anomaly?

Re: MK3 - Problem with ABS - Failed print[s]

What sort of print problems did you have at higher temperatures? 230 is cool for ABS, but not unreasonably cool.

My experience with ABS is that it's usually pretty forgiving of printing too hot. Usually the worst problems I have are support and rafts that become fused to the print and impossible to remove. If you're printing without support or rafts then that obviously won't be an issue.

Re: MK3 - Problem with ABS - Failed print[s]

What sort of print problems did you have at higher temperatures? 230 is cool for ABS, but not unreasonably cool.

My experience with ABS is that it's usually pretty forgiving of printing too hot. Usually the worst problems I have are support and rafts that become fused to the print and impossible to remove. If you're printing without support or rafts then that obviously won't be an issue.

Hard to explain but I've got a pic. First layer went down well. Second layer, which is supposed to follow as a circle on top of the first layer "skipped" on the inside and instead of being a curve decided to stick at only certain places so it made a lot of straight lines instead. Very strange.

Re: MK3 - Problem with ABS - Failed print[s]

Hard to explain but I've got a pic. First layer went down well. Second layer, which is supposed to follow as a circle on top of the first layer "skipped" on the inside and instead of being a curve decided to stick at only certain places so it made a lot of straight lines instead. Very strange.

To me that looks like the perimeter on the inside of the curve isn't adhering to the rest of the print, There's also some weird blobby stuff going on. It could be maybe underextrusion, but that doesn't explain why the problem goes away when you turn the temperature down.

Are you using the default ABS profile for the MK3?

Re: MK3 - Problem with ABS - Failed print[s]

Hard to explain but I've got a pic. First layer went down well. Second layer, which is supposed to follow as a circle on top of the first layer "skipped" on the inside and instead of being a curve decided to stick at only certain places so it made a lot of straight lines instead. Very strange.

To me that looks like the perimeter on the inside of the curve isn't adhering to the rest of the print, There's also some weird blobby stuff going on. It could be maybe underextrusion, but that doesn't explain why the problem goes away when you turn the temperature down.

Are you using the default ABS profile for the MK3?

Exactly - the perimeter on the inside wasn't adhering. And yes, the blobby stuff is weird too. Note that this is an MK2S, but I believe the same hot end.

Yes, I'm using the default ABS profile from Slic3r PE except for the change in temperature.

Re: MK3 - Problem with ABS - Failed print[s]

Exactly - the perimeter on the inside wasn't adhering. And yes, the blobby stuff is weird too. Note that this is an MK2S, but I believe the same hot end.

Yes, I'm using the default ABS profile from Slic3r PE except for the change in temperature.

Okay, so here's my thought process...let's see where this goes.

ABS is different from PLA in that where PLA melts and gets very liquid, ABS has a more gradual melt transition and becomes a thick fluid, and a thinner fluid as you make it hotter. That's why ABS tends to be more forgiving of printing too hot. That's also why I'm skeptical that printing too hot is your root cause.

What you're seeing is that on the first layer the perimeters aren't adhering to the infill or the bed, but when you cool the print temperature it gets better. With ABS when you print hotter it tends to adhere better, so it makes no sense that turning the temperature down would increase adhesion. On the other hand, when you print ABS cooler it will harden faster and hold the shape better.

So maybe the root cause is that your Z height is too high, and the first layer isn't getting smooshed down enough to stick to the bed. If the ABS is soft enough, it will prefer to get pulled behind the nozzle rather than hold its shape, but printing cooler lets it solidify fast enough to not do that.

Try lowering the Z height a bit and see what that does.

Re: MK3 - Problem with ABS - Failed print[s]

I agree - it makes no sense.

I believe my first layer is good. It is squished down (probably more than I need it) and actually adheres well.

Maybe it's a problem with this particular ABS filament. When I get a chance, I'll try another spool (different vendor, different color - not that color makes a difference).

Thanks.