Flex3Drive Direct Adaptor

Got one of these coming for my MK3: https://flex3drive.com/flex3drive/f3d-dda/

A quick Google around didn't lead me to anyone with a Prusa using this. Does anyone here have any experience with it?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

There was someone in the past who looked at it:

https://shop.prusa3d.com/forum/improvements-f14/flex3drive--t1095.html

Re: Flex3Drive Direct Adaptor

https://www.thingiverse.com/thing:2804790

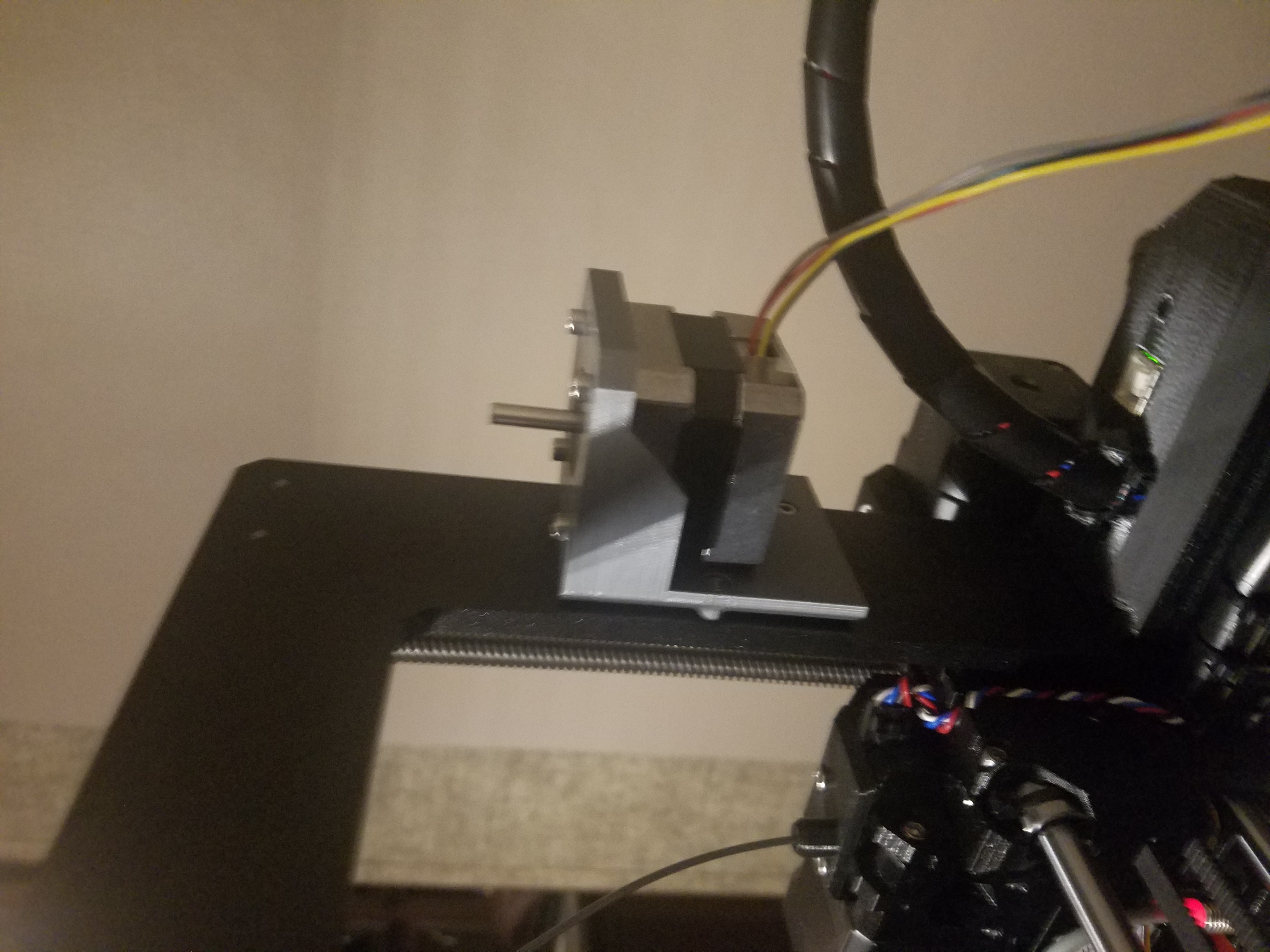

Still waiting on the flex drive adapter to arrive, but created this in preparation. I am using the Raspberry Pi mounting holes on the left of the frame to hold my extruder stepper, and run my flex drive shaft up and over the top of the frame down to the extruder. Here's hoping it doesn't introduce any weird vibrations. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

I'd be interested in hearing your experiences. Are they shipping the adapter reasonably fast, or is there a long wait?

Re: Flex3Drive Direct Adaptor

I'd be interested in hearing your experiences. Are they shipping the adapter reasonably fast, or is there a long wait?

Just got an email back from their support saying mine will be shipping early next week. So about a week delay, not too bad.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Pretty cool concept. If I’m understanding it correctly, we would be able to mount the gearbox directly to where the stepper motor is currently mounted and we would be able to retain the bondtech gears??

Keep us informed when you get it and test it. Curious to see what noticeable improvements come from it.

Re: Flex3Drive Direct Adaptor

Pretty cool concept. If I’m understanding it correctly, we would be able to mount the gearbox directly to where the stepper motor is currently mounted and we would be able to retain the bondtech gears??

Keep us informed when you get it and test it. Curious to see what noticeable improvements come from it.

Yes. Stepper motor gets mounted some place rigid and away from the extruder head, extruder head loses several grams (200ish) of weight to reduce ringing / increase speed, and the geared filler piece jumps it from 1:1 to 40:1 for way higher extruder resolution. I suspect I am opening all sorts of cans of worms with this, but I am really curious if that extra extrusion resolution will be the ticket to perfection on PETG. 🙂

God help whatever filament I extrude at 40:1 in the bondtech. I may cold extrude some toothpicks.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Test fit of the new mount.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Pretty cool concept. If I’m understanding it correctly, we would be able to mount the gearbox directly to where the stepper motor is currently mounted and we would be able to retain the bondtech gears??

Keep us informed when you get it and test it. Curious to see what noticeable improvements come from it.

Yes. Stepper motor gets mounted some place rigid and away from the extruder head, extruder head loses several grams (200ish) of weight to reduce ringing / increase speed, and the geared filler piece jumps it from 1:1 to 40:1 for way higher extruder resolution. I suspect I am opening all sorts of cans of worms with this, but I am really curious if that extra extrusion resolution will be the ticket to perfection on PETG. 🙂

God help whatever filament I extrude at 40:1 in the bondtech. I may cold extrude some toothpicks.

I’m intrigued. Don’t forget to update us. Are there 3D models available for the gear box etc? I wouldn’t mind messing around with it.

Re: Flex3Drive Direct Adaptor

I'd be interested in hearing your experiences. Are they shipping the adapter reasonably fast, or is there a long wait?

Just got an email back from their support saying mine will be shipping early next week. So about a week delay, not too bad.

Super interested in the results you get, was looking at this and the Zesty Nimble a few days ago but couldn't find too many reviews of it running on a i3 style setup.

Re: Flex3Drive Direct Adaptor

Just got confirmation that this will be shipping Monday, going from the UK to the US. Hopefully not too long now. 🙂

Anyone here have experience converting a Prusa direct drive to geared stepper? This is going to take my MK3 from 1:1 to 40:1. My brain wants to think this is just a straight multiplication by 40 on the E steps, any other gotchas you guys can think of?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Just got confirmation that this will be shipping Monday, going from the UK to the US. Hopefully not too long now. 🙂

Anyone here have experience converting a Prusa direct drive to geared stepper? This is going to take my MK3 from 1:1 to 40:1. My brain wants to think this is just a straight multiplication by 40 on the E steps, any other gotchas you guys can think of?

So, did you ever get this? What were your results?

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Flex3Drive Direct Adaptor

So, did you ever get this? What were your results?

Unfortunately not. It went something like this:

Seems like the person running it has a really hectic life right now, but with that level of delays, lack of communication on their part, and in general not following through or providing accurate information... I was ready to bail on the idea.

It may work out for the best, depending on how jltx's extruder redesign project goes. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Unfortunately not. It went something like this:

Seems like the person running it has a really hectic life right now, but with that level of delays, lack of communication on their part, and in general not following through or providing accurate information... I was ready to bail on the idea.

It may work out for the best, depending on how jltx's extruder redesign project goes. 🙂

I knew you weren't using it, I was gonna try to acquire it off you to put on the JLTX project. 😈 mmm 140:1 gear reduction...

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Flex3Drive Direct Adaptor

Unfortunately not. It went something like this:

Seems like the person running it has a really hectic life right now, but with that level of delays, lack of communication on their part, and in general not following through or providing accurate information... I was ready to bail on the idea.

It may work out for the best, depending on how jltx's extruder redesign project goes. 🙂

I knew you weren't using it, I was gonna try to acquire it off you to put on the JLTX project. 😈 mmm 140:1 gear reduction...

Yes, but also keep in mind the stepper issues we're already having at 1:1, and having to modify firmware to 40:1... It was going to be a bit of a task. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Flex3Drive Direct Adaptor

Unfortunately not. It went something like this:

Seems like the person running it has a really hectic life right now, but with that level of delays, lack of communication on their part, and in general not following through or providing accurate information... I was ready to bail on the idea.

It may work out for the best, depending on how jltx's extruder redesign project goes. 🙂

I knew you weren't using it, I was gonna try to acquire it off you to put on the JLTX project. 😈 mmm 140:1 gear reduction...

Yes, but also keep in mind the stepper issues we're already having at 1:1, and having to modify firmware to 40:1... It was going to be a bit of a task. 🙂

Just change Steps per mm, from 280 too..... uhhh...

39,200 steps per mm... ... maybe a bit overkill?

40:1 would be 11,200 steps per mm... Much more appropriate!

I mean 280 steps per mm? Once I put a 0.15mm nozzle on it... *roams off to do complex math*

That's 0.00859029241mm^3 per microstep.

Or when using the 0.15mm nozzle I'm getting, and a 0.05mm layer height... EVERY MICROSTEP... extrudes enough filament to extrude 1.1mm of linear travel.

To say that is *NOT FREAKING OPTIMAL* is an unstatement.

Using a handy-dandy calculator...

0.875 radius

280 = steps per mm

G = is gear reduction.

0.17 = width of extrusion

0.05 = layer height

L = The length of extrusion we are looking for

(π*0.875^2)/(280*G) = 0.17*0.05*L

So with NO reduction.

L = 1.01062mm <-- lulz!

With 3.5:1

L = 0.288749mm <-- not enough

With 40:1

L = 0.0252656mm <-- too much

With 10:1

L = 0.101062 <-- It's totally acceptable, but a touch low.

With 20:1

L = 0.0505311 <--- WE HAVE A WINNER!!!

And just for lols... 140:1

L = 0.00721873 <--- PERFECTION

So honestly, Doing this math. I think the optimal gear reduction is 20:1 if you want a 0.15mm nozzle.

With a 0.25mm nozzle, I think a 10:1 is near optimal.

With a 0.4mm nozzle, a 7:1 is optimal.

With 0.4mm, running a 0.05mm layer height... *ONE* microstep is L = 0.390468. <-- HOLY SMOKES THAT IS TERRRRIBLE

Even running 0.4mm at 0.2mm layer height. L = 0.097617!!! The precesion of our machines on X and Y is around 0.05mm. The extruder is the WEAKEST link on our printer.

So honestly. I don't think 40:1 is "extreme overkill". It's closer to where it should be, than it currently is.

1*7 = 7

40/5.7 = 7

1 = 7 times too low.

40 = 5.7 times too high. (assuming you don't have a 0.25mm nozzle)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.