First Layer Surface Irregularity

Hi to all,

i am using PRUSA i3 MK3 which i assembled myself and owned this for aprox. 6 months. This is my first printer so that my experience on 3D printing is not too much. But i am very interested and spent lots of time on printing and also i built up an enclosure for the printer made up of wood and leaving the electronic circuitry and power supply outside.

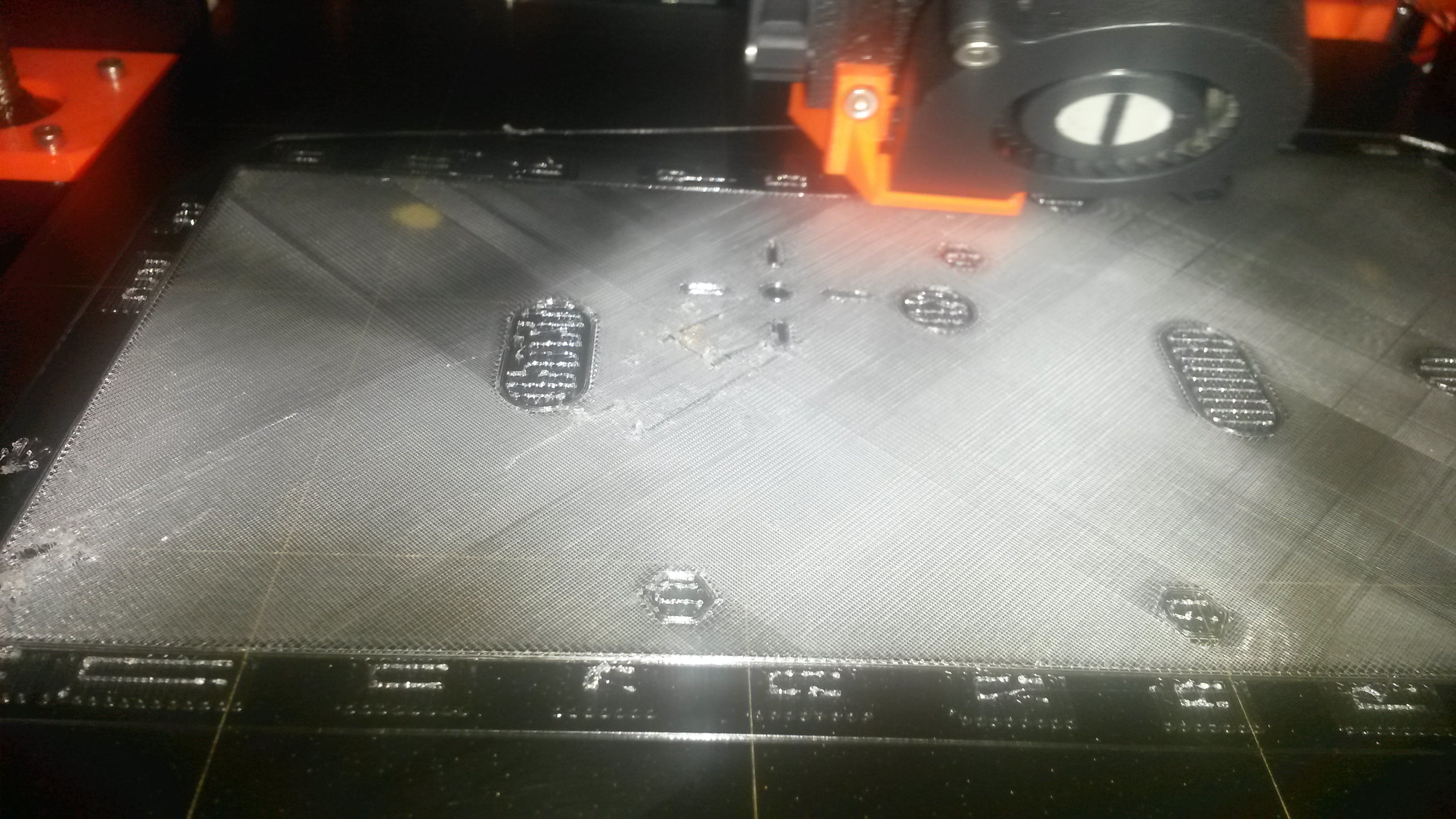

My print outs are sufficient in quality but there is always better. Today i started printing a large base area object. I am sharing with you a photo which is taken about at the end of the first layer. Here, some areas seem to me sticking good whereas some areas seem horrible. Actually, there is a good sticking area between the 2 badly stuck areas which i signed in the picture. So, i can only think that there should be an irregularity on the surface of the spring steel sheet. I do not know if this is true or not. Or how can i measure this irregularity or test it? I even do not know if my proposal is true or not. What do you think of the possible cause of this failure? And how can i fix it? By the way, the print material is clear(natural) PETG by eSUN company. The failure slightly disappears while printing following layers but while printing with ABS(green), these failures attract attention more.

I use slic3r PE (default settings for Generic PET and Prusa i3 MK3) Extruder Temp : First Layer : 230 C - Other Layers: 240 C ------ Bed: First Layer : 85 C - Other Layers : 90 C

Nozzle diameter : 0.4mm

Re: First Layer Surface Irregularity

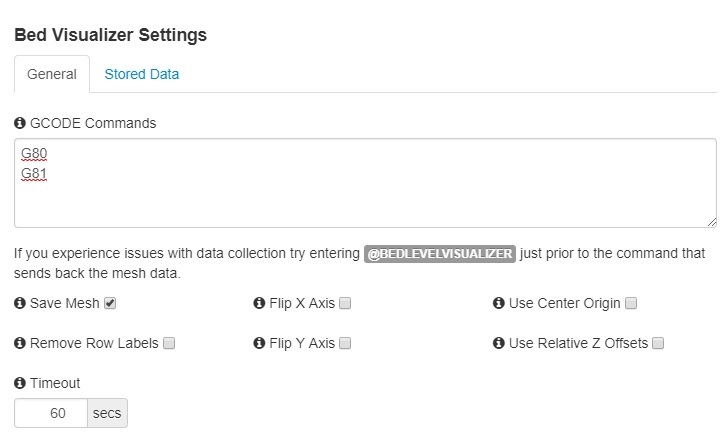

Additionally, I use the printer with Raspberry Pi 3 B+ (Octoprint running) connected and as you possibly know there is a plugin called "Bed Visualizer". Below is the settings i use :

And here is the bed visual i get when the printer bed is cool:

Re: First Layer Surface Irregularity

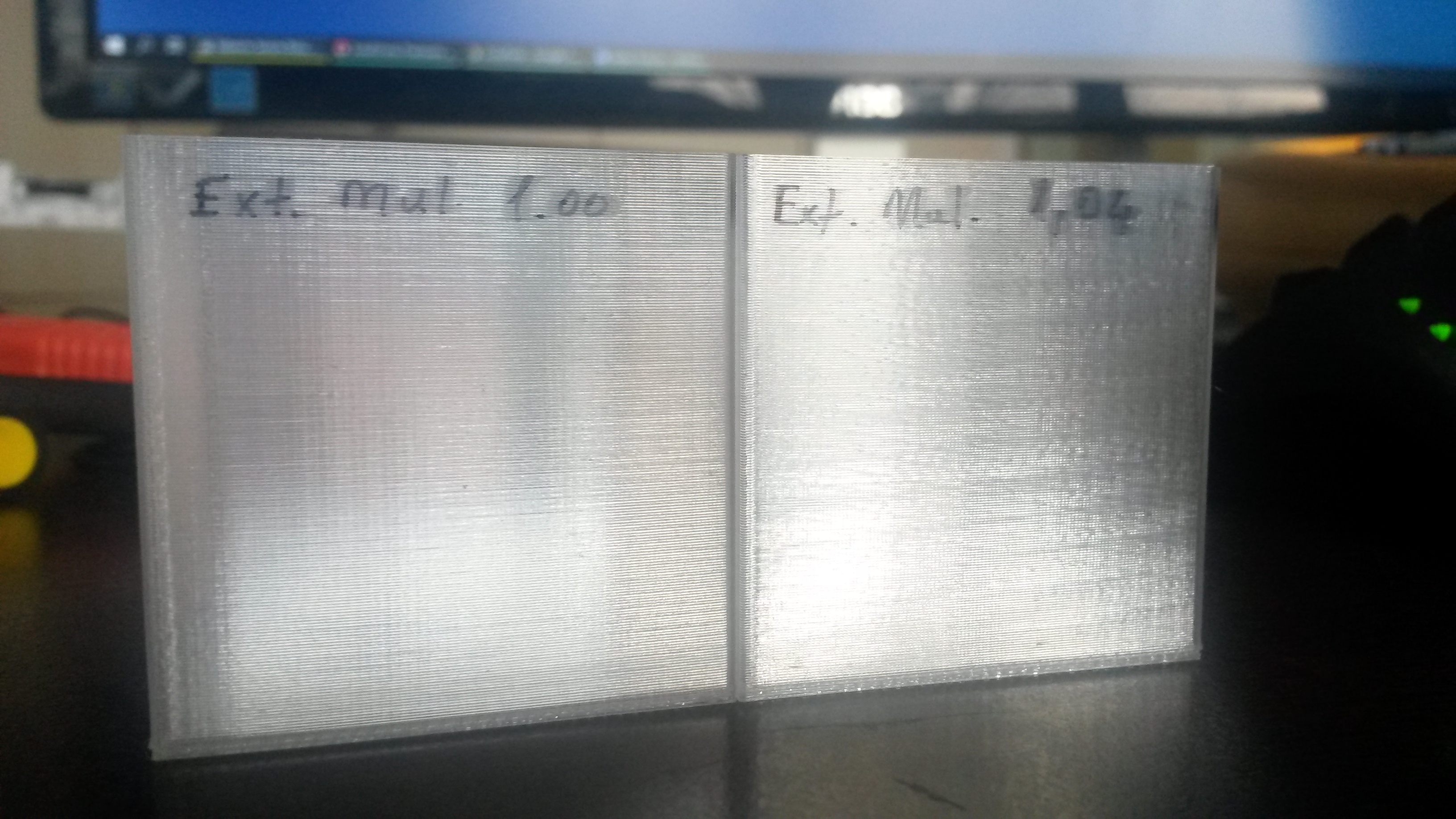

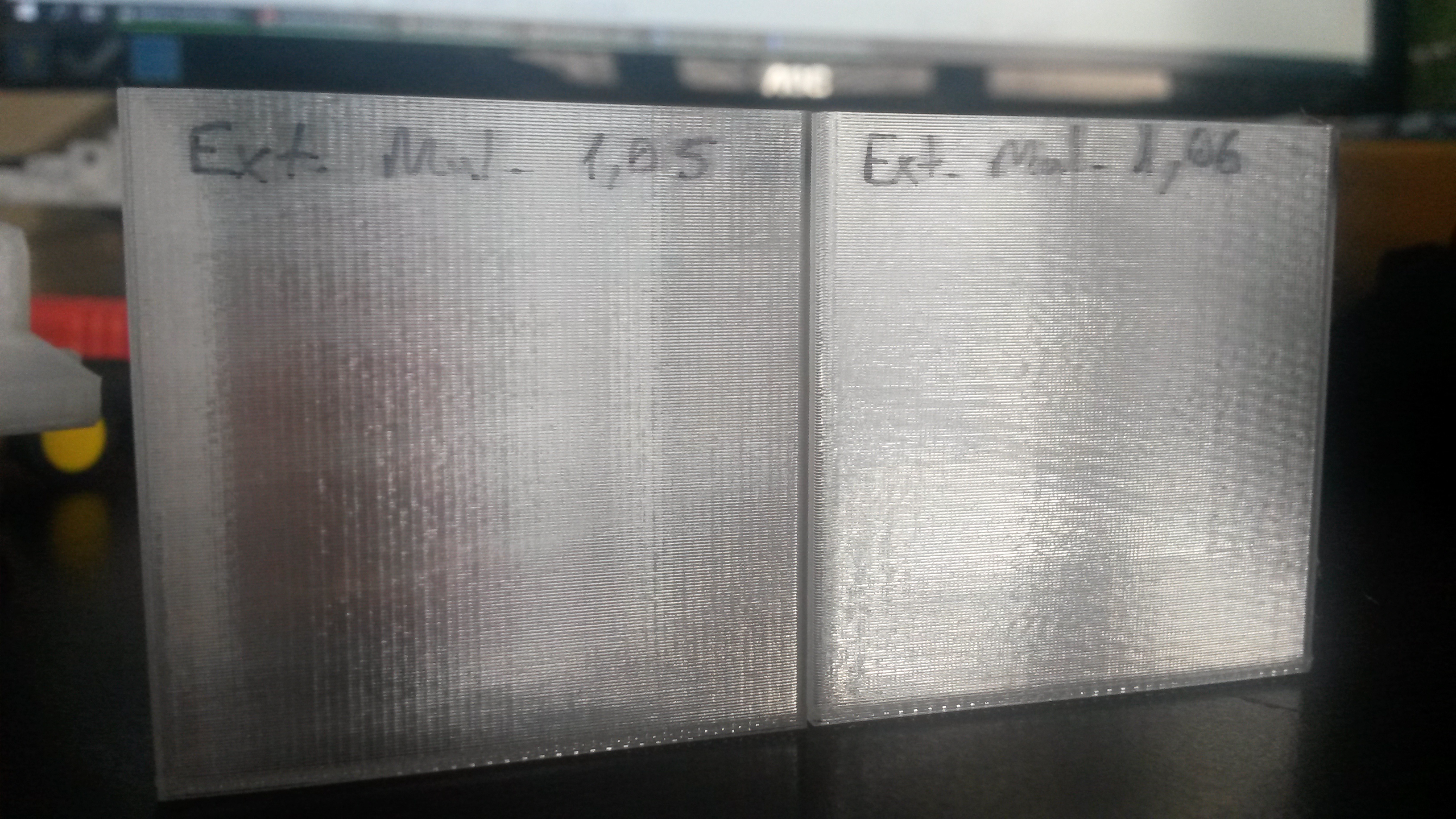

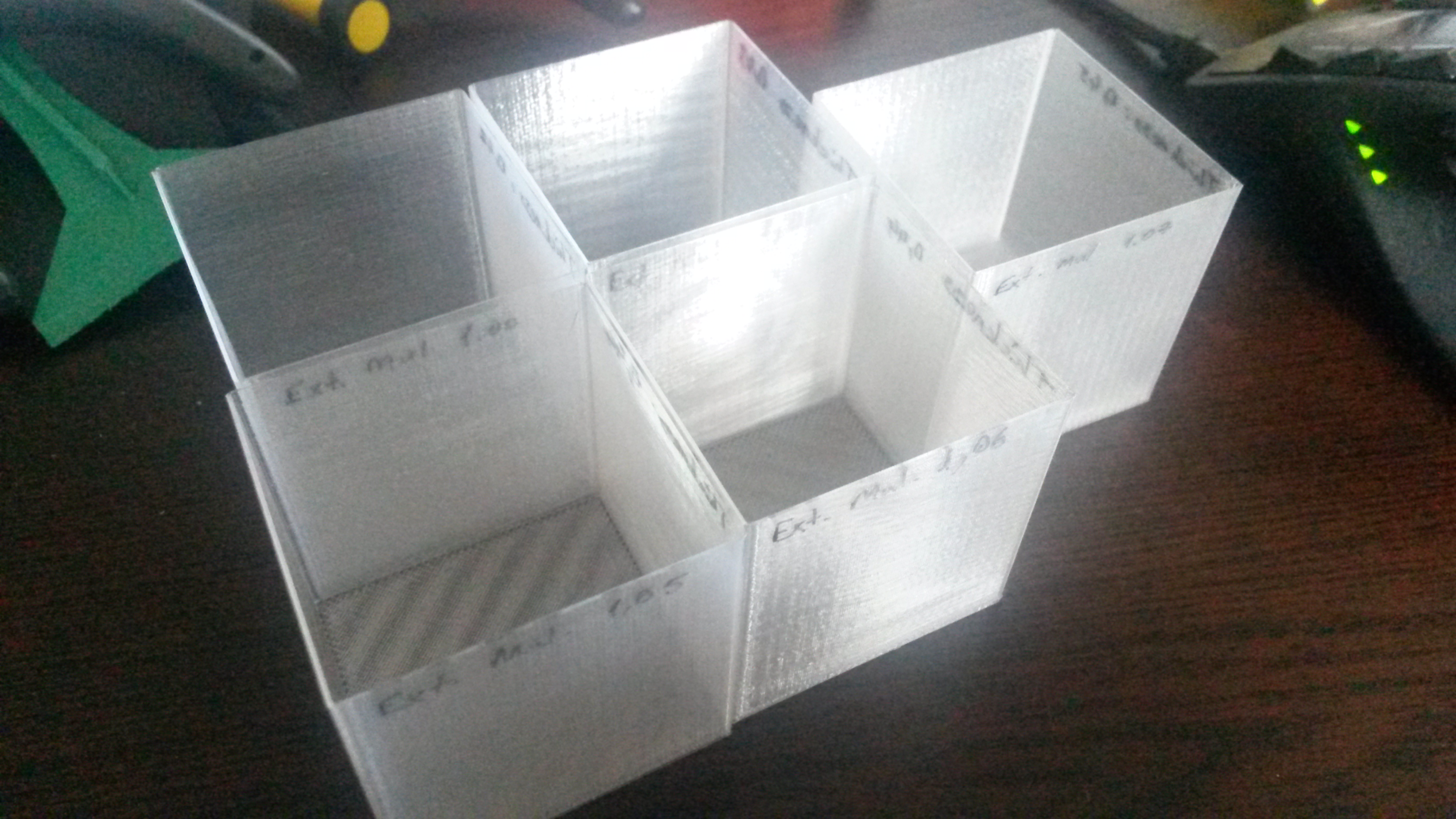

There is also an object test i made with current settings. It is a 40mmx40mmx40mm cube with "spiral vase mode" selected in Slic3r. The position of the object is center of the bed on all printouts. The purpose of these prints were to see the affect of "Extrusion Multiplier" value on prints. As i saw, when Ext.Mul. = 1.00, it was perfect but when i changed it some other value, there always became a linear pattern on cubes' faces. I do not know the affect's correct name (Moire effect? , ghost effect?, ...) Anyway i do not have any problems with this effect, all of the prints are satisfying me. I just wanted to attract your attention that the printer successfully prints such a thin-walled(0.45mm) object on the center of x-y plane (heated bed). I do not imagine what to do for the edges of the heated bed where i have problem explained above. I do not know if there is a setting i should adjust.

Any help would be appreciated. Thanks in advance.

Tankut

Re: First Layer Surface Irregularity

Today i changed the steel sheet with the powder coated one, recalibrated the printer and started to print a new large bottom surface object. The quality is much better. I can say it is perfect.

Now i have another question in my mind. Is this steel sheet also going to be like the previous one over time? The previous one was not powder coated. Is this related with the situation here? Any ideas? What is really going on?