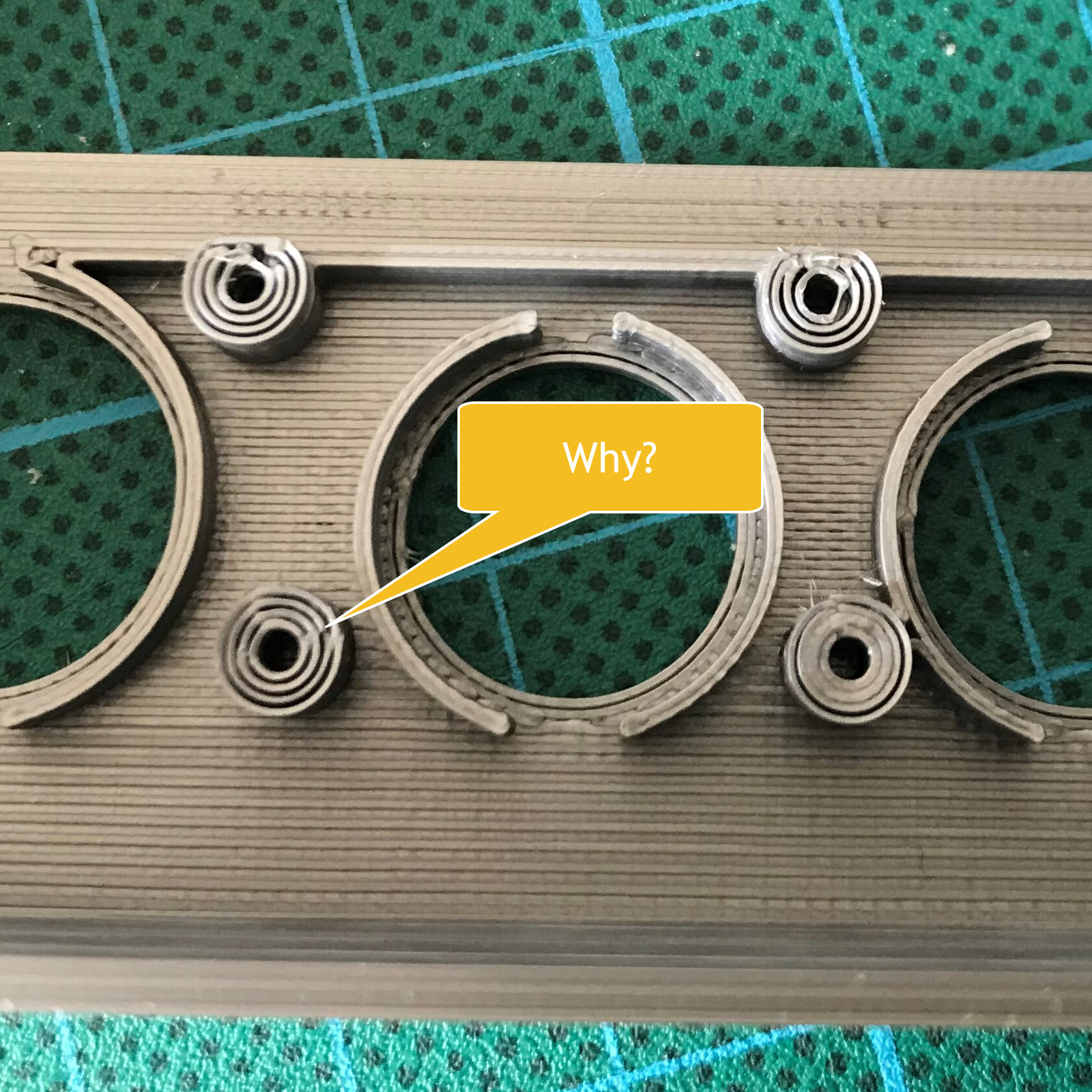

Extrusion Issues on Circular Objects

Hello,

I have run into following problem with both slic3r and PrusaControl:

As to be seen, the screw studs have insufficient infill to be really useful (everything else seems perfect).

I posted above picture on Facebook and it was suggested that I perform a extruder calibration as per https://mattshub.com/2017/04/19/extruder-calibration/ .

I went through all steps and can confirm that the extruder extrudes perfect 100mm with the original E=280 firmware settings.

Also with an extrusion multiplier of 1 and the default MK3 settings, the following test cube came out perfectly (slic3r):

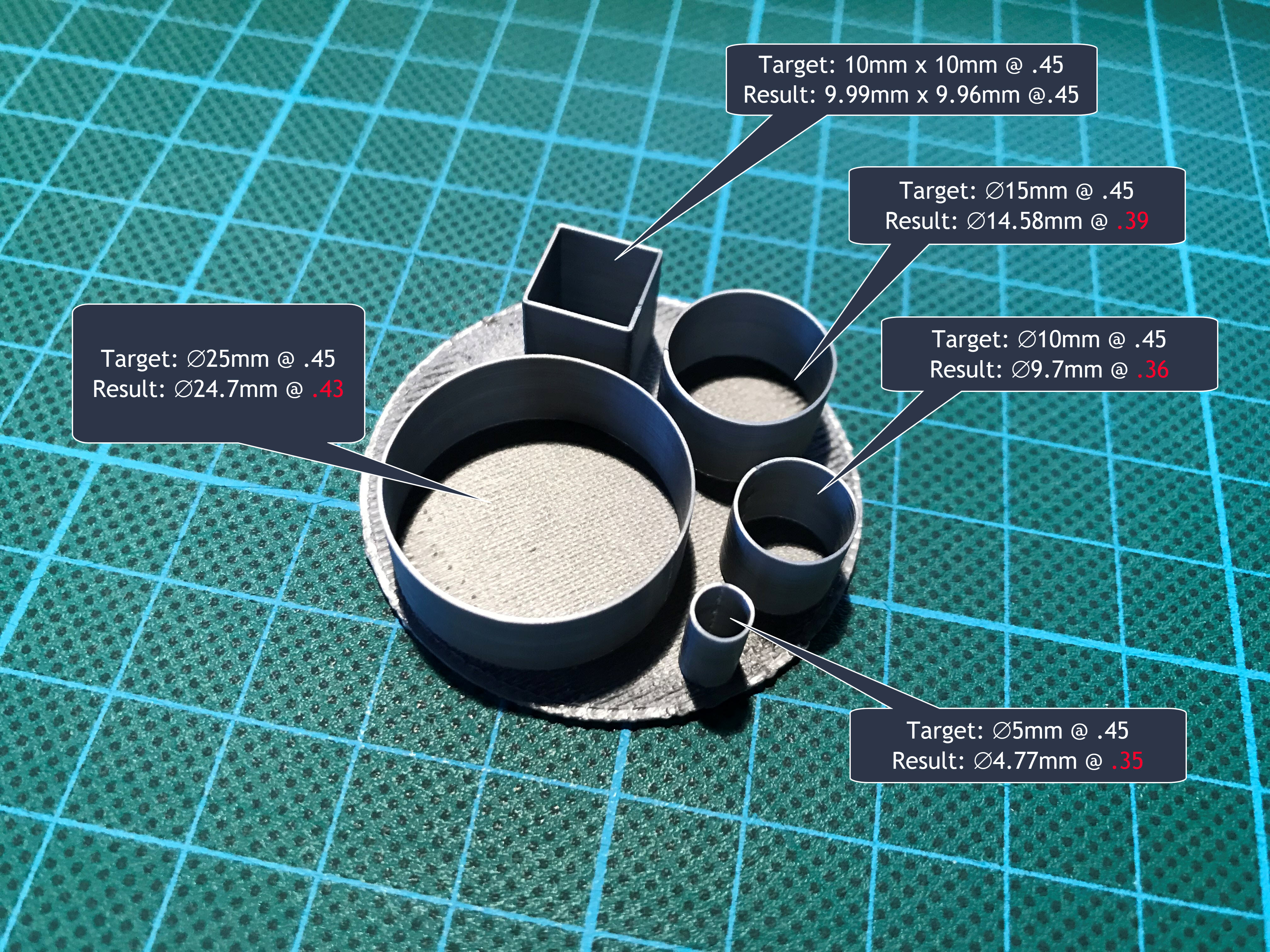

Then, on a hunch, I compared extrusion on both round and rectangular objects:

As far as I can tell, the extrusion between a rectangle and an circle vastly differs.

Subjectively I am sure that the circle is printed too fast - the 15mm circle is printed in less time than the 10mm x 10mm square (which has the same circumference as an circle with 12.73mm).

Fact, the smaller the circle, the finer the extrusion. At 1.6mm diameter the width is .32 instead of the expected .45!

Now this might be a general issue with slic3r and PrusaControl or a firmware issue?

My Guess is firmware - maybe some sort of path optimization, as used on CNC's but which does not adjust the extrusion?

cu,

Michael