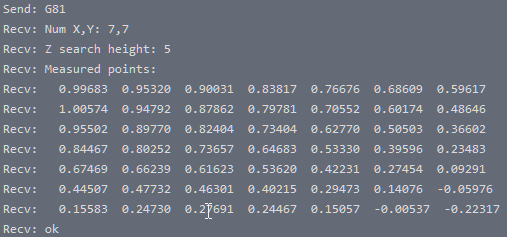

Bed level correction / G81 values - WAY off

The way I'm reading these:

.99683 is the BACK LEFT (closest to the wires)

-.22317 is the FRONT RIGHT (how can there be a negative distance between the probe and bed?!)

But after several frustrating attempts at adding shims and re-tightening screws it doesn't seem to correlate at all. So right now I have two problems:

1. ~1mm variance across the bed in almost any direction, this is clearly visible just by dismounting the bed and holding it up to a straightedge. I know my X-plate is flat (I checked), and the mounting height of my y axis rods is fairly close too (<.1)

2. There doesn't seem to be ANY way to adjust at all. If your rods, plate, and bed are not perfectly square the first time, then PINDA seems quite happy to run mesh level, spit out "slightly skewed, good job!" while recording values like this and then print out garbage if I try and print anywhere but the middle 30-40mm of the bed.

I feel like I would much rather have a sheet of paper and some thumbscrews at this point, very little faith in PINDA at the moment.

Re: Bed level correction / G81 values - WAY off

I've been pondering the same thing here. In the areas where the G81 command spits out negative values I notice the bed is actually being depressed when the G80 command is being executed so my guess is the PINDA is triggered so low that it reads below the actual bed level. No idea how that happens and it's not always doing it.

I ordered some shims in an attempt to level the bed mechanically. From highest to lowest point the bed is off by 0.4mm in my case. Not too bad over a distance of 250mm given the manufacturing method used so ordering a replacement bed probably won't fix anything. If I read the manual correctly, the PINDA results can only correct +/-50 microns for some reason. Using 0.1mm shims I should be able to get within that range.

I did notice that undoing the bed and then simply reinstalling it according to the tightening sequence in the build manual causes some bed points to shift in height by a few tenths of a millimetre. I'm going to heat my bed up to a high temperature and leave everything to relax and bed in somewhat in a desperate attempt to get some inconsistencies out. After cooling I'll attempt to shim it up and report back.

Also something I notice in doing a load of G80+G81 measurements is that the bed takes about 10 minutes to fully warm up after the set temperature has been reached. If you do measurements immediately after reaching, say 50degC, and another 10 minutes later you'll get results that are significantly different. I'm going to see if I can change the start Gcode so that it leaves the bed to soak for 10 minutes before a print starts.

I'm aware of below topic but due to my mechanical engineering background I prefer to solve issues the mechanical way first 🙄

https://shop.prusa3d.com/forum/prusa-i3-kit-building-calibrating-first-print-main-f6/hyperfine-bed-leveling--t4330.html

Re: Bed level correction / G81 values - WAY off

Did a few hours of shimming the bed today. I see your point regarding the lack of correlation between the PINDA results and bed height. Adding a 0.1mm shim to a corner didn't make the bed height move at all at times... It took a bit of trial and error but eventually I managed to get the maximum difference between points to go from 0.4mm to 0.15mm in 5 iterations. I took 3 G80+G81 measurements between iterations to monitor the progress.

Does anyone know how the firmware creates a 7x7 matrix of points from only 9 measurements? I assumed linear interpolation between points but that doesn't work out... That algorithm may be part of the lack of correlation between placing shims and the probe results.

My aim was to get every point within 0.05mm so I'm not there yet but at least my 3x3 test patch pattern now all print nicely with good bed adhesion rather than a mix of low, good and high Z-levels. Happy with that for now but will no doubt feel the need for perfection at some point 🙂

Re: Bed level correction / G81 values - WAY off

My guess, is it creates a 7x7 from a 3x3, by some basic math.

GRID EXAMPLE

11 12 13 14 15 16 17

21 22 23 24 25 26 27

31 32 33 34 35 36 37

41 42 43 44 45 46 47

51 52 53 54 55 56 57

61 62 63 64 65 66 67

71 72 73 74 75 76 77

Is a example of the unique points on a 7x7 mesh.

I would guess the 9 points measured by the Pinda probe are...

11 12 13 14 15 16 17

21 22 23 24 25 26 27

31 32 33 34 35 36 37

41 42 43 44 45 46 47

51 52 53 54 55 56 57

61 62 63 64 65 66 67

71 72 73 74 75 76 77

From your readout that explains how there can be "negative" numbers as well.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.