3D Printer Test: PLA and PETG

Hello to all,

I'm trying to print a 3D test from here:

https://www.thingiverse.com/thing:1363023

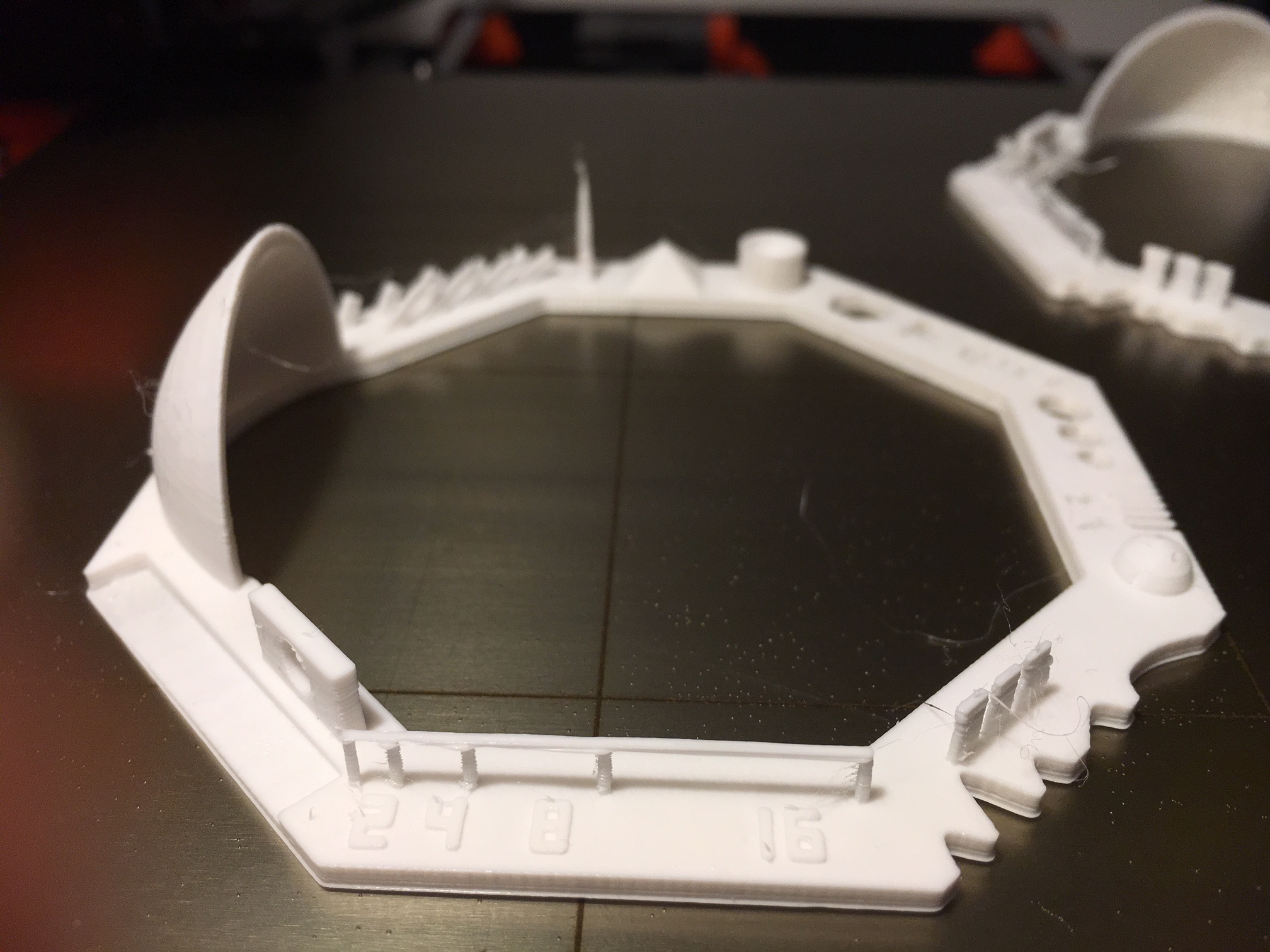

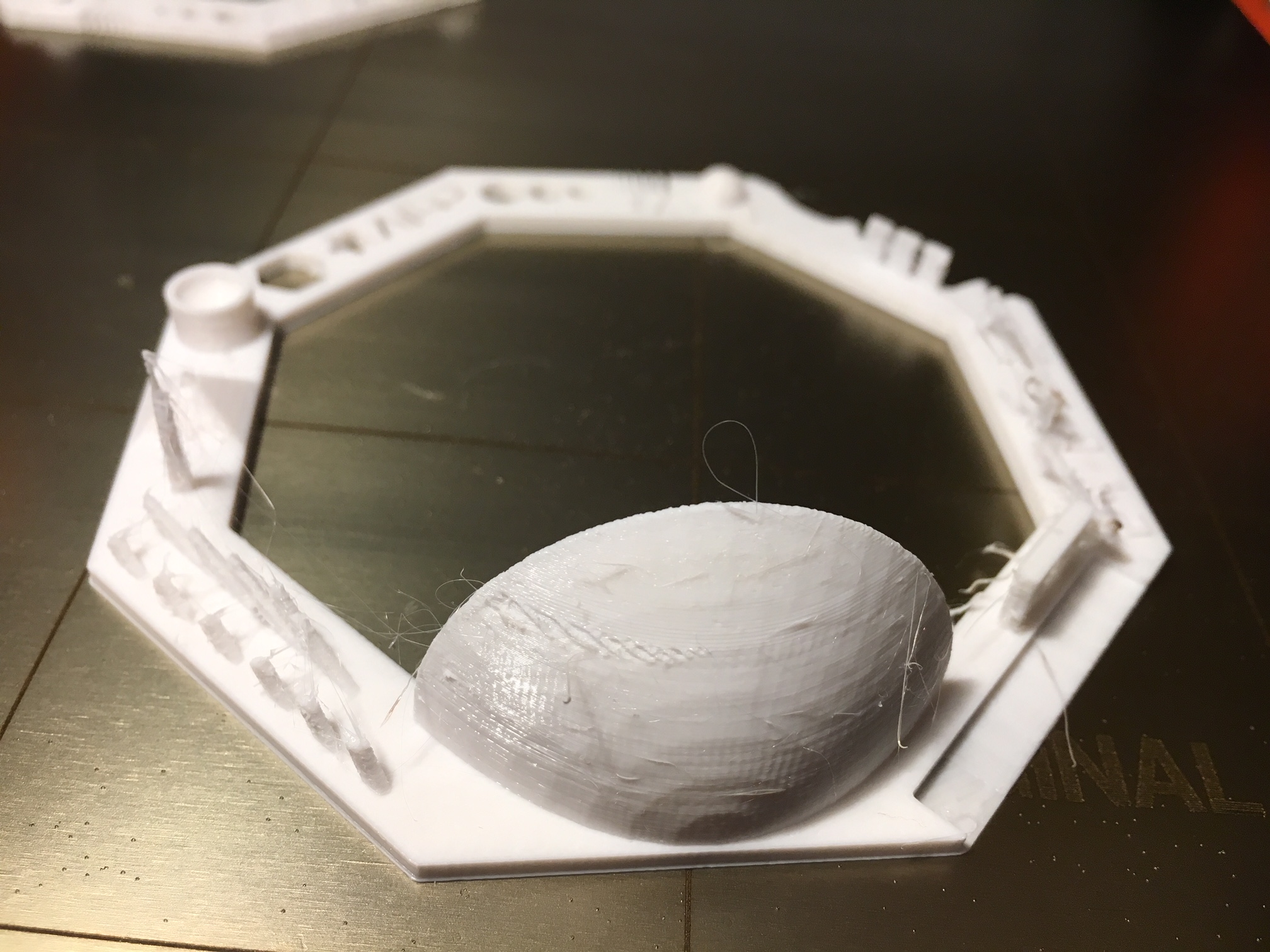

Well, seems that my PLA test is not so bad, using a enough cheap PLA, printed at 215°C 1st layer then 210°C on a 60°C bed.

Here the results:

Until here ok, then I've tried the test with an eSun PETG, and the result is not so good...

(let me use the next post, because cannot add more attachments...)

Re: 3D Printer Test: PLA and PETG

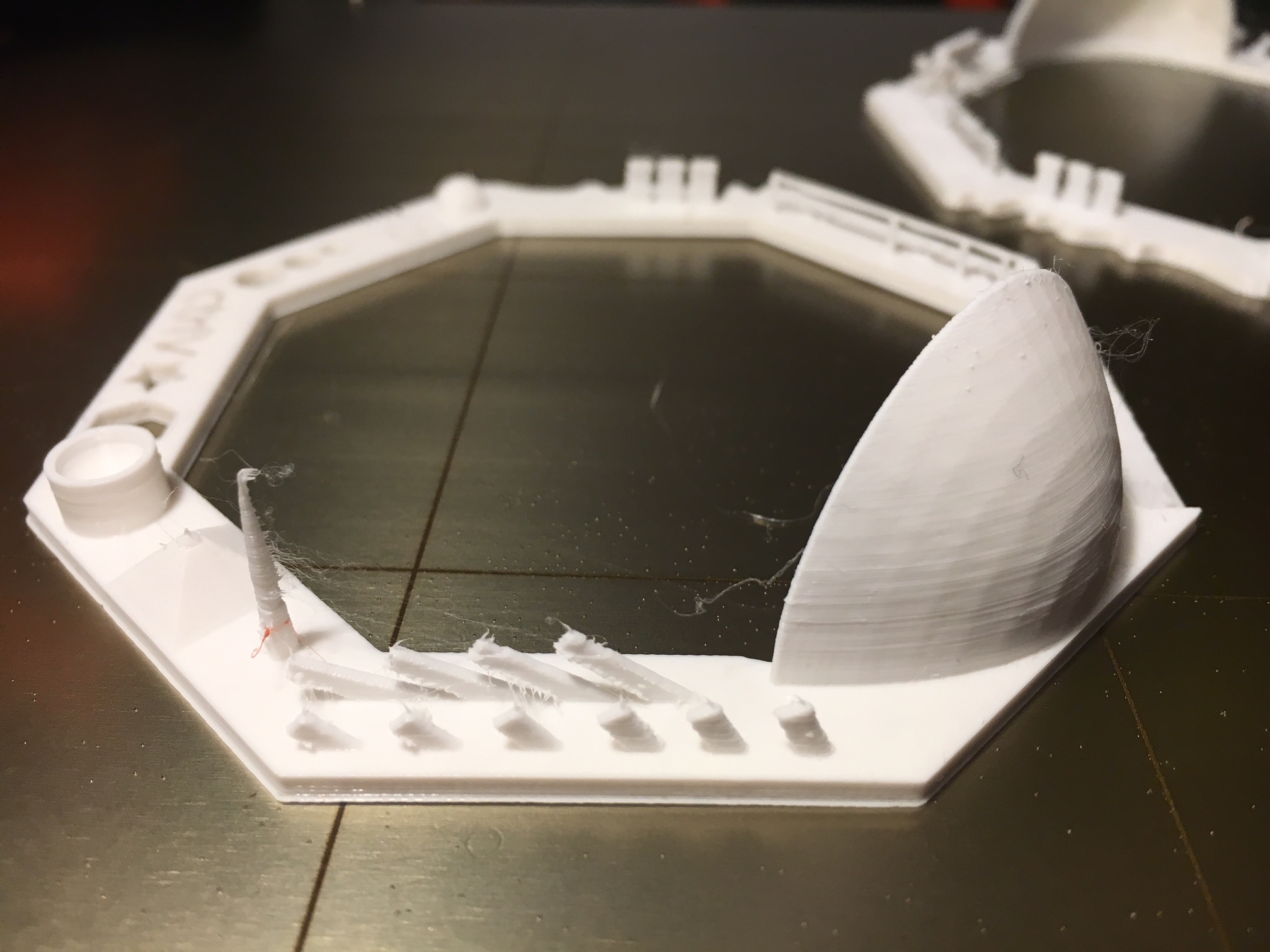

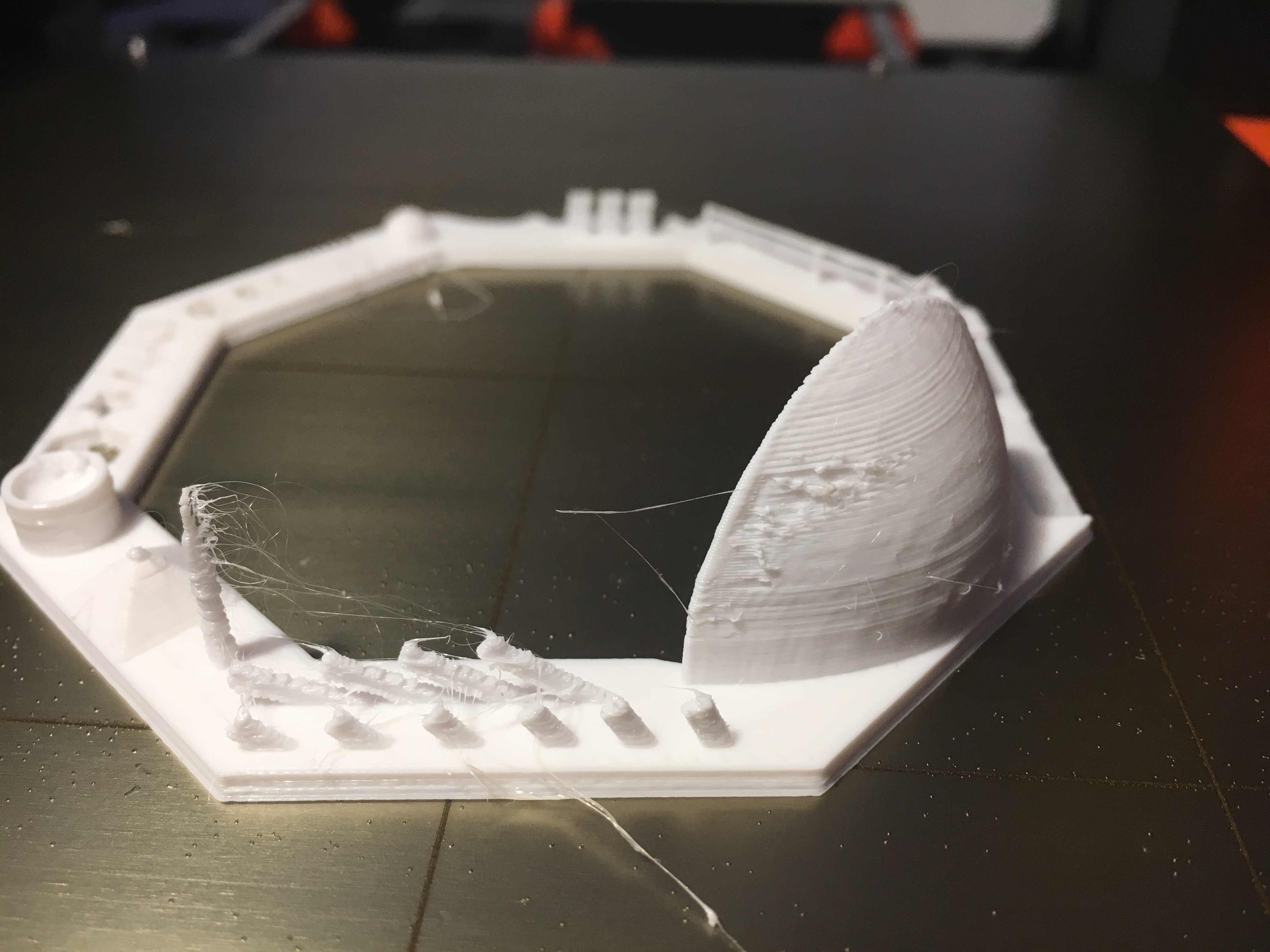

Here as follow my test on PETG. Printed at 230° 1.st layer, then 240 on a 70°Bed

Why is it so bad?

I've used a 0.1mm layer, 20% infill and default Slic3r settings (selecting a Prusa PET as profile).

Suggestions?

If needed I could post here my two gcode used.

Thanks, Simon

Re: 3D Printer Test: PLA and PETG

really its not that bad if thats default settings.

stringy: play with retraction. i use 1-2mm at 55mms

bridges: +speed and -extrusion override

I don't have good luck with petg at .1 either, it seems to like higher layer heights

Re: 3D Printer Test: PLA and PETG

really its not that bad if thats default settings.

Oh, great to read it!

stringy: play with retraction. i use 1-2mm at 55mms

Ok, I'll give it a try. set to 1.5 @ 55mms

bridges: +speed and -extrusion override

Well, more speed is ok. I've never heard about extrusion override.

I've set Bridge from 1000 mm/s2 to 1500.

I cannot find the extrusion override in Slic3r 🙁

I don't have good luck with petg at .1 either, it seems to like higher layer heights

Good! I'll try with a 0.2 layer hieght and post the results.

I've read from you curtis.c2 as well as now googling that PETG needs a taller layer (that's ok).

Meanwhile, I've another question.

I've read that PETG needs a different Z-layer correction. Actually for my MK3 it was set at -0.8 (near to correct the PINDA, I know) and I've lways printed on PLA.

With PETG do I need to increase the distance between nozzle and bed (ie, -0.7) or reduce the distance (ie -0.9).

My first test on -0.8 that I've stopped some parts didnt get attached on the bed so I've set it to -0.9 and I've print the above test.

But this article tolds me the opposite: https://letsprint3d.net/2017/08/08/how-to-print-petg/

I should print with the extruder higher (so -0.8 or -0.7 in my case, not -0.9!). But increasing the filament would not attach on the bed...

At least looking those images:

As always, if someone else has suggestions, thanks!

Simon

Re: 3D Printer Test: PLA and PETG

Hello,

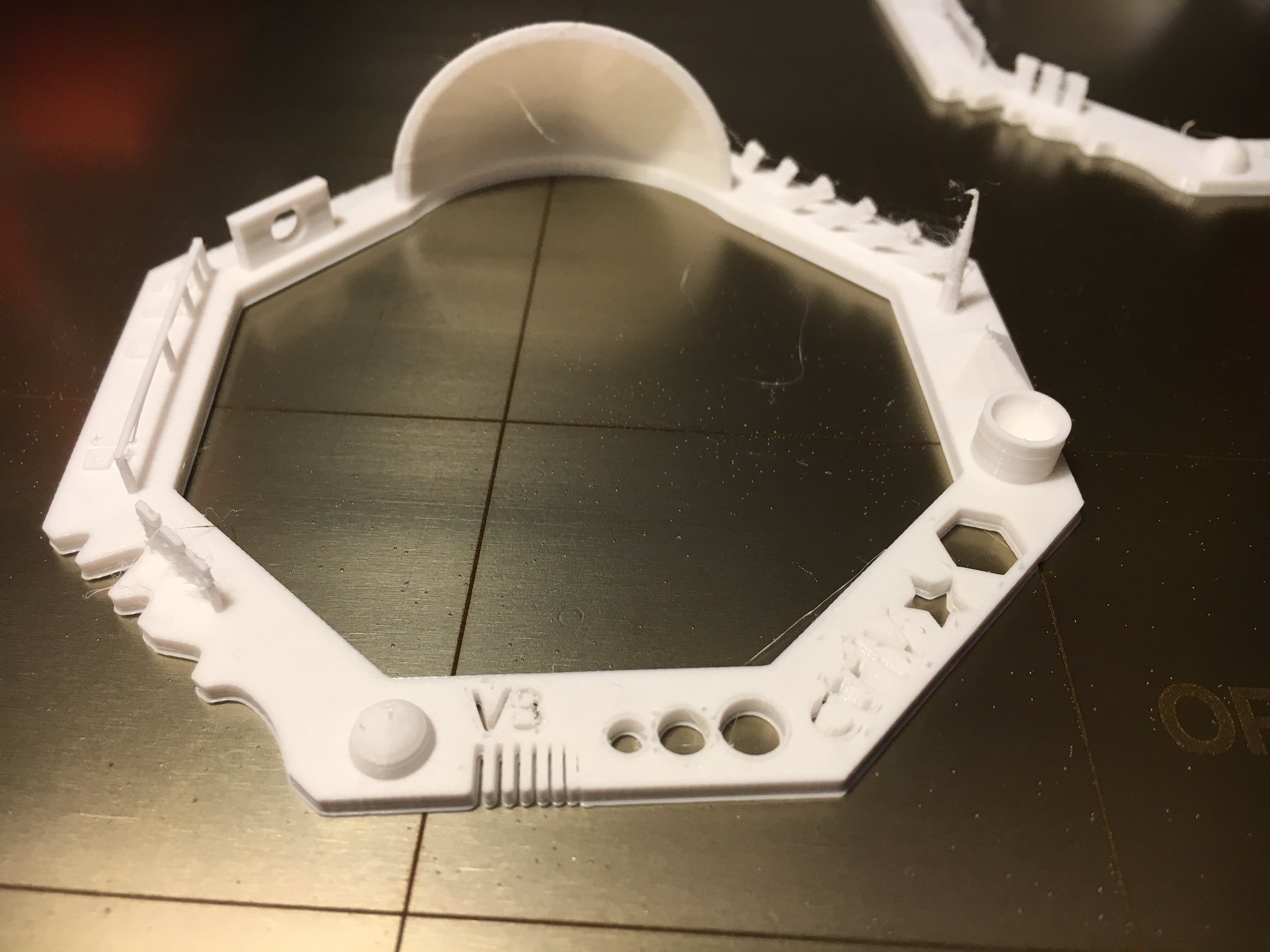

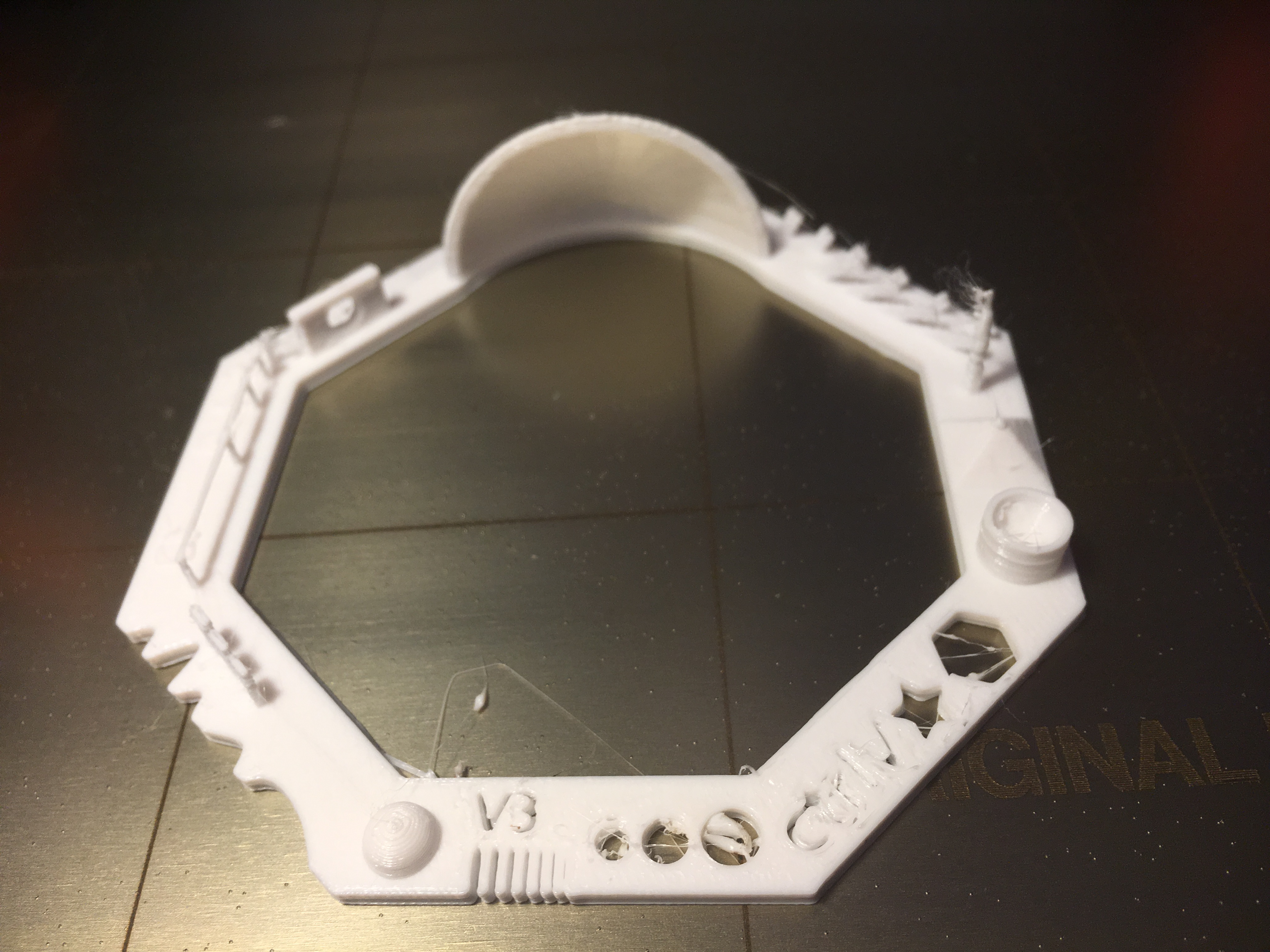

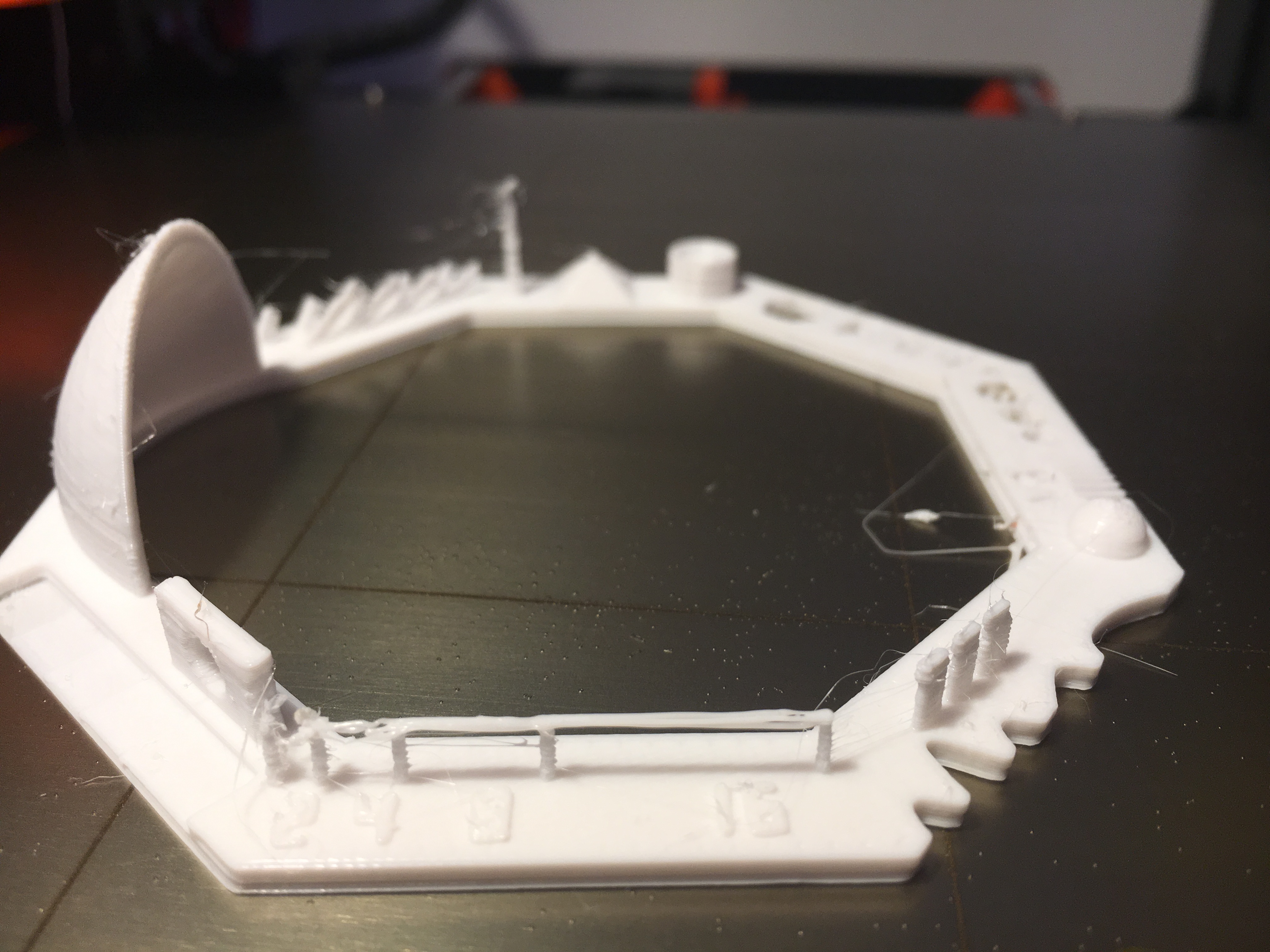

Here my last results applying:

FAN: 100% always

Bridge: from 1000 to 1500 mm/s2

Retraction length: from 0.8 to 1.5 at speed 55 mm/s

Layer: from 0.1 to 0.2

A lot of stringing and a part of the shell on the right has always some scratches... why?

Here the 3th circle has this bulb inside. Seems it has detected a crash and restarted from there. But what is this crash system in the MK3?

So, seems the bridges went better, even if strange the short bridge fails and the log went ok.

Other suggestions??

Thanks, Simon

Re: 3D Printer Test: PLA and PETG

Again, it's me 🙁

I'm testing now increasing the multiplier after testing the length of a 50mm of extrusion against the really length of the filament used.

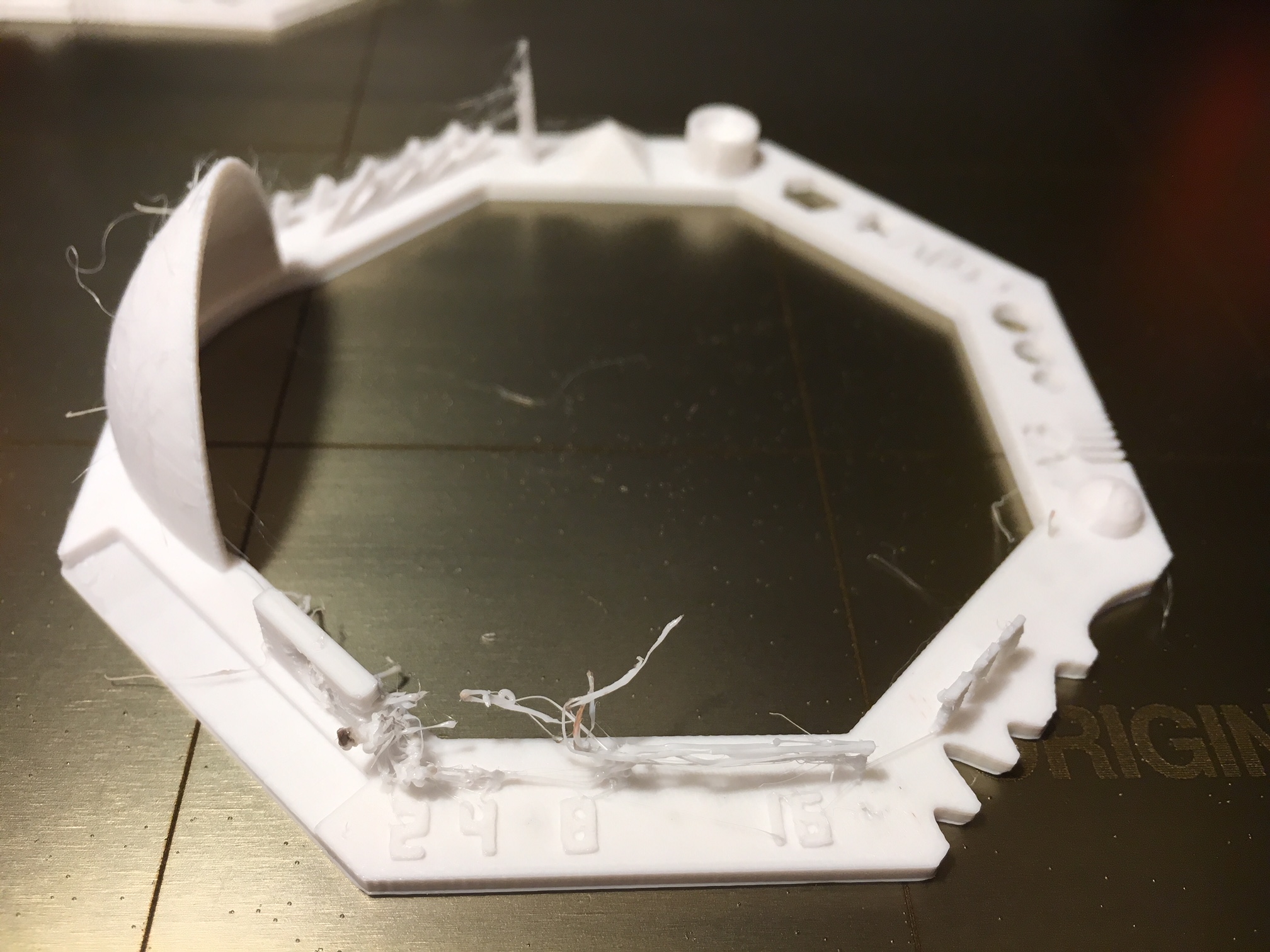

BTW I think the biggest problem is on stringing and blobbing. The extruder has filament all around the extruder itself. I think that is causing problems on stringing and blobbing. I'm pinting now as follow:

Starting from Prusa PETG:

FAN: 100% after 3th layer

Bridge: 1500 mm/s2

Retraction length: 3mm speed @ 55 mm/s

Temperature 225°C

Bed: 75°

The filament is an eSun PETG (230-250°C).

Ideas? 🙁

Re: 3D Printer Test: PLA and PETG

Regarding the Z offset for PETG, here's what I have found works perfectly.

It's very important to start too high and work your way down until the holes disappear. With PLA and the built in Z offset test, it's very easy to be too squished and still get fair results. The above method will put you within .01 or so of a great PETG result in my experience. The top of the first layer will feel very smooth (except near the edges, if you have firmware with no Linear Advance...), and you should have minimal gooping, etc.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: 3D Printer Test: PLA and PETG

The extruder has filament all around the extruder itself. I think that is causing problems on stringing and blobbing. I'm pinting now as follow:

yeah, welcome to petg. sticky and messy.

too hot, and it strings, blobs, and sags

too fast, and it strings

too slow, and it blobs and sags

not enough retraction, and it strings and blobs

too much retraction, and it gets sticky and causes jams

The common wisdom is that PETG is an amazing wonder-material, matterhackers even advertises it as being easier to print than PLA. Either this esun PETG is not all that great (i'm fighting with it myself right now) or I'm missing something big.

Also, look at the printed parts on your mk3. They're not that pretty, right? But they ARE strong and temp-resistant. Thats the use-case for PETG.

Re: 3D Printer Test: PLA and PETG

Thanks for both suggestions, I'll give a try and let you know.

Meanwhile I've hit often the extruder calibration thema.

I've measured 150mm and marked on the filament. Then, via Octoprint, I've extruded 100mm. The length to the 150mm was 51mm, so the extruder hax extruded 99mm thinking it's 100mm. That means 100/99 = 1.01. Should I use it as multiplier?

@curtis,which settings are you using? So I could give it a try or you can make the same test I'm trying from thingiverse (posted at the beginning.

Thanks, Simon

Re: 3D Printer Test: PLA and PETG

@curtis,which settings are you using? So I could give it a try or you can make the same test I'm trying from thingiverse (posted at the beginning.

Thanks, Simon

Try this one so you dont have to keep printing that thing. Its called torture test for a reason :p Much easier to just print specific tests to dial in each setting.

Re: 3D Printer Test: PLA and PETG

The common wisdom is that PETG is an amazing wonder-material, matterhackers even advertises it as being easier to print than PLA. Either this esun PETG is not all that great (i'm fighting with it myself right now) or I'm missing something big.

ESun PETG works fine for me. I actually thought better than PLA. I used the default PETG settings. I always print a Benchy as a test with any new filament. This was printed on a MK2s.

Re: 3D Printer Test: PLA and PETG

Try this one so you dont have to keep printing that thing. Its called torture test for a reason :p Much easier to just print specific tests to dial in each setting.

https://www.thingiverse.com/thing:22263

Oh, yeah, that would not so bad, so I have faster results 😉 Thanks.

Curtis, which settings do you have changed?

ESun PETG works fine for me. I actually thought better than PLA. I used the default PETG settings. I always print a Benchy as a test with any new filament. This was printed on a MK2s.

Hello!

I'm using MK3. Default settings for all parameters? Bed and Extruder temperature as well?

I'm noticing material on the extruder, maybe from the beginning of my tests.

This will cause (maybe?!) blobbing. The material forms a torus around the extrusion point. At some points this materia got detached from the extruder and falls into the print. If I'm lucky it's pushed away furing printing.

The eSun has printing temepratures between 230-250. I've printed most of the tests at 230 or 225, with same results.

I've no idea what test now :'(

Re: 3D Printer Test: PLA and PETG

I'm noticing material on the extruder, maybe from the beginning of my tests.

This will cause (maybe?!) blobbing. The material forms a torus around the extrusion point. At some points this materia got detached from the extruder and falls into the print. If I'm lucky it's pushed away furing printing.

The eSun has printing temepratures between 230-250. I've printed most of the tests at 230 or 225, with same results.

I've no idea what test now :'(

Perhaps you have a slight blockage in the extruder?

I was using 240 temp. Perhaps try this?

And see this post here: https://shop.prusa3d.com/forum/original-prusa-i3-mk2-f23/petg-filament-advice-t1810.html#p14057

And try the Benchy from the sd card.

Ciao

Re: 3D Printer Test: PLA and PETG

I do eSUN PETG at 240, works really fine. No stringing and good bindings between the layers.

---

Gert

Re: 3D Printer Test: PLA and PETG

Oh, yeah, that would not so bad, so I have faster results 😉 Thanks.

Curtis, which settings do you have changed?

235-240, 55mms overall and 50% perimeters. .75 retract at 30mms, force retract on all. 20% constant fan with with 100% bridging. Very minimal stringing on that test with no wipe enabled, can completely eliminate it using wipe+retract but it makes a mess with small details sometimes so I leave it off for now.

that gives me a fairly respectable benchy in terms of overhangs and layer adhesion but my surface finish is still not great. My filament probably needs a good drying since I see the occasional bubble.

I'm noticing material on the extruder, maybe from the beginning of my tests.

This will cause (maybe?!) blobbing. The material forms a torus around the extrusion point. At some points this materia got detached from the extruder and falls into the print. If I'm lucky it's pushed away furing printing.

yeah its really sticky, even the smallest ooze will get dragged along and stick to things. make sure to grab or wipe it before it starts, use a nice wide skirt, keep your travel movements quick and hope for the best.

Re: 3D Printer Test: PLA and PETG

235-240, 55mms overall and 50% perimeters. .75 retract at 30mms, force retract on all. 20% constant fan with with 100% bridging. Very minimal stringing on that test with no wipe enabled, can completely eliminate it using wipe+retract but it makes a mess with small details sometimes so I leave it off for now.

that gives me a fairly respectable benchy in terms of overhangs and layer adhesion but my surface finish is still not great. My filament probably needs a good drying since I see the occasional bubble.

Goood morning!

Hello curtis, I've applied you settings and... well, printing I've noticed an important aspect, maybe the root cause of everything.

The extruder became dirty (curling) and filament sticks on the nozzle mainly because it was hitting a little the filament during the extrusion.

So, it was a matter of "Live Z tuning". Even if it was already mentioned as possible issue, I've thought it was not possible, because I had tuned it from the beginning.... but wrong.

Changing filament from PLA to my first tests on PETG I've seen the filament did not stick on the bed. This was the reason to decrease the extruder heigth until the filament was squashed. Maybe in this way the extruder was scratching the filament the same time during the extrusion.

Now, increasing the distance by 0.1mm it's much better.

I've another question for you all.

Is it possible that ONLY the Z tuning was causing me this blobbing and filament sticks on the nozzle from the very first layer until the end of the print?? Well the 3d test is more or less 5mm heigth.

I've applied the curtis settings as well, but the seems not so far from the default. I'll give a try to the default settings as well, but only to know if Z axis could be the main cause.

Thanks all!!

Simon

Re: 3D Printer Test: PLA and PETG

235-240, 55mms overall and 50% perimeters. .75 retract at 30mms, force retract on all. 20% constant fan with with 100% bridging. Very minimal stringing on that test with no wipe enabled, can completely eliminate it using wipe+retract but it makes a mess with small details sometimes so I leave it off for now.

that gives me a fairly respectable benchy in terms of overhangs and layer adhesion but my surface finish is still not great. My filament probably needs a good drying since I see the occasional bubble.

Is it possible that ONLY the Z tuning was causing me this blobbing and filament sticks on the nozzle from the very first layer until the end of the print??

Simon

very likely, you need a larger clearance. adding .1 to my live Z for PLA is the sweet spot for me. Check out this article from Rigid.Ink, they recommend and extra .2

https://rigid.ink/blogs/news/175700615-petg-filament-heres-what-you-need-to-know

remember its very sticky, so if its too low then its going to pick up blobs and bits. overextrusion can cause the same thing on higher layers.

Re: 3D Printer Test: PLA and PETG

very likely, you need a larger clearance. adding .1 to my live Z for PLA is the sweet spot for me. Check out this article from Rigid.Ink, they recommend and extra .2

https://rigid.ink/blogs/news/175700615-petg-filament-heres-what-you-need-to-know

remember its very sticky, so if its too low then its going to pick up blobs and bits. overextrusion can cause the same thing on higher layers.

Hi curtis,

Is this Z-layer GAP acomplished using the Live Z Tune from the Prusa Menu?

This should increase the Z offset for every layer, right? BTW, the layer heigth (print quality, default 0.2) would be untouched.

So Z-offset moves handles the gap between bed and extruder, and layer heigth would increase always by 0.2.

But if the extruder is higher than in the PLA, printing a full flat 1 layer square (thing on the Z layer test from Prusa, only one layer) this would cause in a square not flat filled, but in a sort of snake filament. Or not?

Hope I've explained my doubt. Thanks for the support!

Simon