Z Banding Improvement

Okay so I recently upgraded my Z motors to lead screws ( https://www.pololu.com/product/2268 ) in an attempt to fix a Z banding issue I was having. It may not have been a terrible problem, but it was annoying enough for me that I needed to find a fix.

So after installing the new Z motors, which look great, I STILL got Z banding. I re-aligned the Z axis and lubricated the lead screw, but this only made a marginal improvement. Then during a test print, I played with one of the Z motors and noticed that it was free to rotate during the print. I thought this was odd, because the Z motors should lock in place to ensure that the X axis remains exactly at the correct height.

So I went and looked through the code and noticed in the configuration.h the following:

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z true

#define DISABLE_E false // For all extruders

#define DISABLE_INACTIVE_EXTRUDER true //disable only inactive extruders and keep active extruder enabled

So for some unknown reason (maybe to conserve energy?) the Z axis driver is disabled between movements! I went ahead and changed that to false and re-uploaded the code - prints are now smooth as butter!

I don't know if anyone else was having this issue but my prints have never looked better. They look FAR better than the parts shipped in my original package. Hope this tip will help others and possibly find it's way into the next FW update.

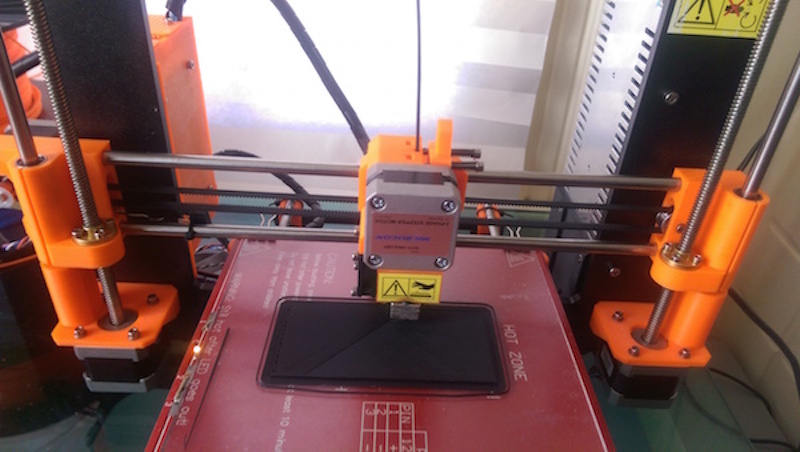

The pictures below show the original part I received with my Prusa i3, a modded version of that part that I printed with the old threaded rods (and after some slight calibrating), and my newest test prints after setting the Configuration.h line to "false."

Re: Z Banding Improvement

Interesting, thx for info.

IMHO maybe its set to true to avoid idle motor noise, but I will try to modify it like you did :-).

Nice mod btw. Can you add STLs for modded X idler and X motor ends?

Re: Z Banding Improvement

I also have the 8mm lead screw motors, but have decided not to fit them to the Prusa as I didn't think they would achieve an improvement that would be worth the time. I do intend building another printer at some time, so I will use them with that.

My guess is that the power to the Z motors is turned off to prevent overheating of the motors and early failure due to excess current draw whilst they are not in use. As far as I know this is the situation with all versions of Marlin - the default is to keep the Z motors disabled between moves.

The problem is microsteps. Keeping the motors disabled at full steps is pretty much OK as the motors will hold the axis, but at a microstep, constant current is required on the coils to do this. Josef has a calculator for layer height so that you can calculate which layer heights are achieved with full step movements.

However this is only good if you can calibrate your Z end stop to a full step, and you have a 1/16th chance of doing that. Best thing to do is to turn off micro-stepping on the Z axis.

The 8mm lead screws (4 x 2mm) will need a different layer policy - I think multiples of 40 micron layers in order to achieve full step movement.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Your results look great, Jack! Thanks so much for sharing this.

It would be nice to hear from Josef if changing the firmware like Jack did could create any problems with the motors.

If its really just a power consumption/noise consideration, then I would definitely change that firmware like Jack did.

Re: Z Banding Improvement

Please note, we print the production parts mostly on vintage 3mm version. Some of those printers are 2 years plus old.

But we are going in the direction you talk about here and locking the Z motors provide better results 😉

Re: Z Banding Improvement

Hi

Just noticed that in version 2.2.2 the DISABLE_Z is already set to false. So if you are running the latest firmware, it's already done.

Peter

EDIT Here's the link to 2.2.2: https://github.com/prusa3d/Prusa-i3-Plus

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Hi

Just noticed that in version 2.2.2 the DISABLE_Z is already set to false. So if you are running the latest firmware, it's already done.

Thank you Peter! Since version 2.2.1 is still posted as the latest firmware on prusa3d.com I am sure not too many people will have noticed this.

Will try the new firmware today.

I noticed that besides the usually named firmware files like "175-RAMBo1-3a-en.hex" there are new "metal" versions of the 1.75mm files like "175-RAMBo1-3a-en-metal.hex".

Whats that about?

(Hoping for an all metal original Prusa i3 😀 )

EDIT: Theres a new "LS" firmware as well for the 1.3a Rambo: "175-LS-RAMBo1-3a-en.hex" ❓

Re: Z Banding Improvement

The "metal" version has higher max temps for the V6 hot end (which I happen to be using...).

Basically, in use, there is no difference between the V6 and Lite6.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Sorry this took me so long, just been really busy with work lately.

Josef, yeah I figured they were just printed quickly. Just used for a comparison. Glad to see that change made in the firmware.

If anyone still wants the stl files for the threaded rod upgrades, I've posted them here. You need the new Z bottom, Z top, X-End Motor, and X-End Idler. I have 2 versions of the X-Ends because I stupidly purchased threaded rods that were too short to reach the top of the frame, so I redesigned the X-ends to house the lead nut on the bottom of the part as opposed to the top. BUT, if you buy the lead screws that are long enough to reach the top, use the "long lead screw" version.

If anyone wants the STEP files, I can make those available too. (One more thing, there are 2 versions of the X-End Motor (Short Lead Screw): one with designed supports, and one without. Use whichever is easier to print.)

https://www.dropbox.com/sh/wkl5nk61s3b7nlc/AAANiiJjT5yZ5Petsttn6MRIa?dl=0

Re: Z Banding Improvement

Thank you so much for posting those files! I'm thinking very strongly about switching to lead screws on my printer except by using couplers on my current motors, so these will be super useful.

Re: Z Banding Improvement

Yeah I highly recommend it! They've made a big improvement for me. But, I will say that I had pretty good prints from the threaded rods before, but I couldn't always get consistent results. After switching to the lead screws (IMPORTANT: And changing the FW code to lock the Z axis), I get consistent, smooth walls.

With regards to your approach, I actually like the idea of using a coupler. I have another idea to use an 8mm ball bearing at both the top and the bottom of the lead screws to keep them perfectly aligned, and use a flexible coupler to connect the motors. The idea here is that it is pretty difficult to get perfect alignment from the base of the motor to the top of the threaded rod, but if the threaded rod is held in alignment by the bearings, then the motor doesn't need to be perfectly aligned.

Notice how easily the smooth rods are aligned since they are held at both the bottom and the top of the Z axis. Same concept here. If you decide you want to give this strategy a try, shoot me a message and I'll whip up a design for it.

Re: Z Banding Improvement

Jack

There could be an issue if you secure the threaded rods at the top. This would not allow any lateral flexing at all, and occasionally it is needed as the X axis rises.

Locking the lateral movement in three places is not a good idea. Two maximum.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Peter,

I only intend to lock the axis in two places: the top and bottom. If you purchase good lead screws, they should be straight, or VERY close. If there is a rigid attachment to the Z motor, then you are more likely to get misalignment. But if you lock the top and bottom to the frame itself and use a flexible coupling to connect the motor, then you have some flexibility at the motor-lead screw junction but still have a nice, straight path for vertical travel.

That's the idea anyway. I personally think that bowing in the threaded rod is OKAY, but it's not really a substitute for lead screws, which are designed for linear motion and will keep the X axis moving in a straight path.

Jack

Re: Z Banding Improvement

While I'm still considering going with leadscrews I have recently had a thought about taking a hopefully more straight 5mm rod and polishing it to get smoother motion out of it. then using the files you provided and then using this http://www.thingiverse.com/thing:1189599 as an anti backlash device. Then it would make sense to me to capture the top of the 5mm rod with a newly printed z top that could hold a bearing. That way the rod would only be constrained by its connection to the stepper shaft and at the top by the bearing.

Re: Z Banding Improvement

Jack

Are you suggesting that the lead screw should not be connected to the X Axis? 😉

Assume that the rods are 250mm long and are out by 1mm, but both top and bottom are not allowed lateral movement.

What will happen when printing a tower that is 200mm tall? Banana?

You need to allow the threads to move laterally at the top, otherwise (worst case) the machine could pull itself apart.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Peter

Touche.

Didn't think of the X axis as a connection point. Well you might be right. It is only an idea.

I would like to point out that the smooth rods are not perfectly straight and they are braced at 3 points (if you include the X axis). I would assume if you get good enough quality, you should get very small low tolerance for straightness.

Anyway, it would need some testing to see if it actually causes an improvement or just further issues.

Jack

Re: Z Banding Improvement

Jack

The linear bearings are also not precisely 8mm; they are slightly more and that will be sufficient enough allowance for any irregularities in SS (or chromes steel) smooth rods.

I think is one were to pay the extra for SS threaded rods, one would note that they are pretty damned straight.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Z Banding Improvement

Yes, the SS threaded rod I bought is very, very straight. I was able to source locally a 1 meter SS threaded rod for $7. Not that much more than what the original replacements would have cost me locally.

Re: Z Banding Improvement

If stainless steel threaded rods do the trick for you, then by all means, go with those. As Richard said, they are very cheap. If anyone is interested, M5 SS threaded rods are found here for cheap. Don't know how good the quality is, but they are stainless steel: https://www.fastenal.com/products/details/MR2541000A20000

Anyway, I can say that I have two Prusa i3s at the moment. One has the upgraded lead screw motors and the other uses my original M5 threaded rods. I cannot produce the same quality with the M5 version as my lead screw version.

That being said, I never upgraded to stainless steel threaded rods, but I still believe that using lead screws (which are designed for linear motion) will produce better results than threaded rods.