Part cooling Dual Fans

Hi,

I am toying with an idea:

For some fast PETG printing (and PLA also) the airflow is not enough for me. I tried some other fan nozzle designs but with not much success. For testing I printed four pieces which have a narrow overhang and tend to curl up when printed to fast.

One result was that the orienetation of tha parts has big impact. pointing to the front or right gives best result (least curling). So with more air it is maybe again interesting to build a nozzle which leads the air more around the print nozzle.

Also fast printing PETG needs some more heat and then a good cooling to prevent stringing.

I isolated my heater block with kapton band, so no problem with 100% air so far, guess I can add more layers of capton or use a different nozzle desing.

I think the clearance of 5mm between the fans is enough. But testing will tell, for the idea it is only a matter of printing the part longer.

What do you think?

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Part cooling Dual Fans

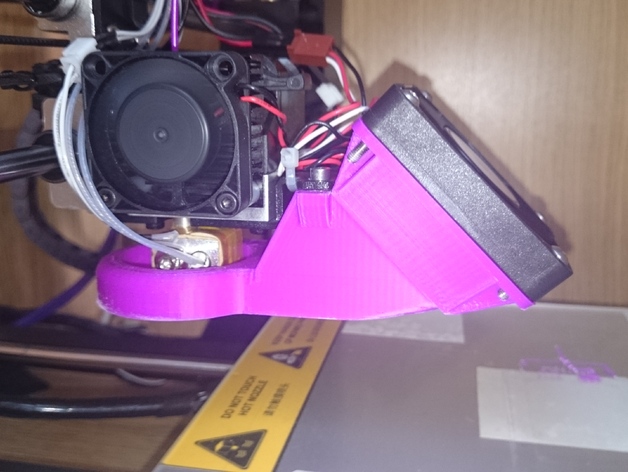

I'm not a fan ( 😎 ) of dual fan solutions. Aren't there bigger ones? Also, I think that the best solution would be one of those round/toroidal air diffusers, like this (not mine, just found on google):

How did you isolate the heater block with kapton band? could you post a picture? Thank you.

Re: Part cooling Dual Fans

Well Kapton, just take some time and put the kapton tape on your heater. Ok let the nozzle free and open 😛 Three or four layers is enough.

I will try next to make better holes into the kapton tape where the nozzle should poke through, My actual "artwork" keeps loosing some kapton from time to time when material melts and I remove it too early.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Part cooling Dual Fans

The PINDA probe is quit in the way to do it proper like this. My Velleman k8200 uses a server PSU fan and such a solution, when the fan turns up 100% you think a jet airplane starts...

Hmm. Maybe I try with this solution also, Stage 1 would be the normal fan nozzle and couple a server fan.

I wonder how much current the RAMBO can handle for the fans? The server ones take 0.5A....

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Part cooling Dual Fans

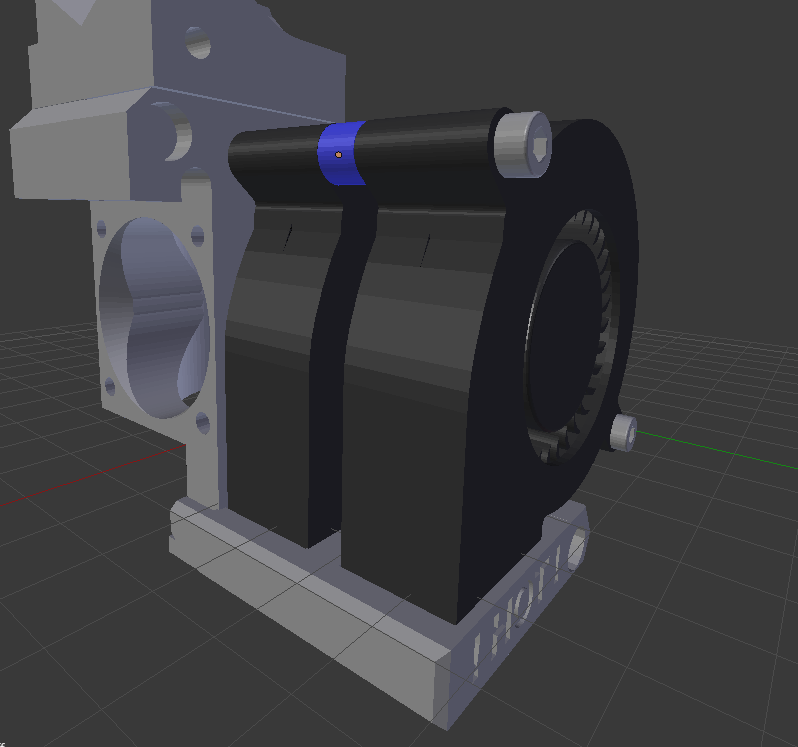

Next step: 😉

Re: Part cooling Dual Fans

I wonder how much current the RAMBO can handle for the fans? The server ones take 0.5A....

Data sheet here: http://www.infineon.com/dgdl/irlml6346pbf.pdf?fileId=5546d462533600a401535668a336262e

But be aware that the output shares the 12V rail with other components via the same fuse.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…