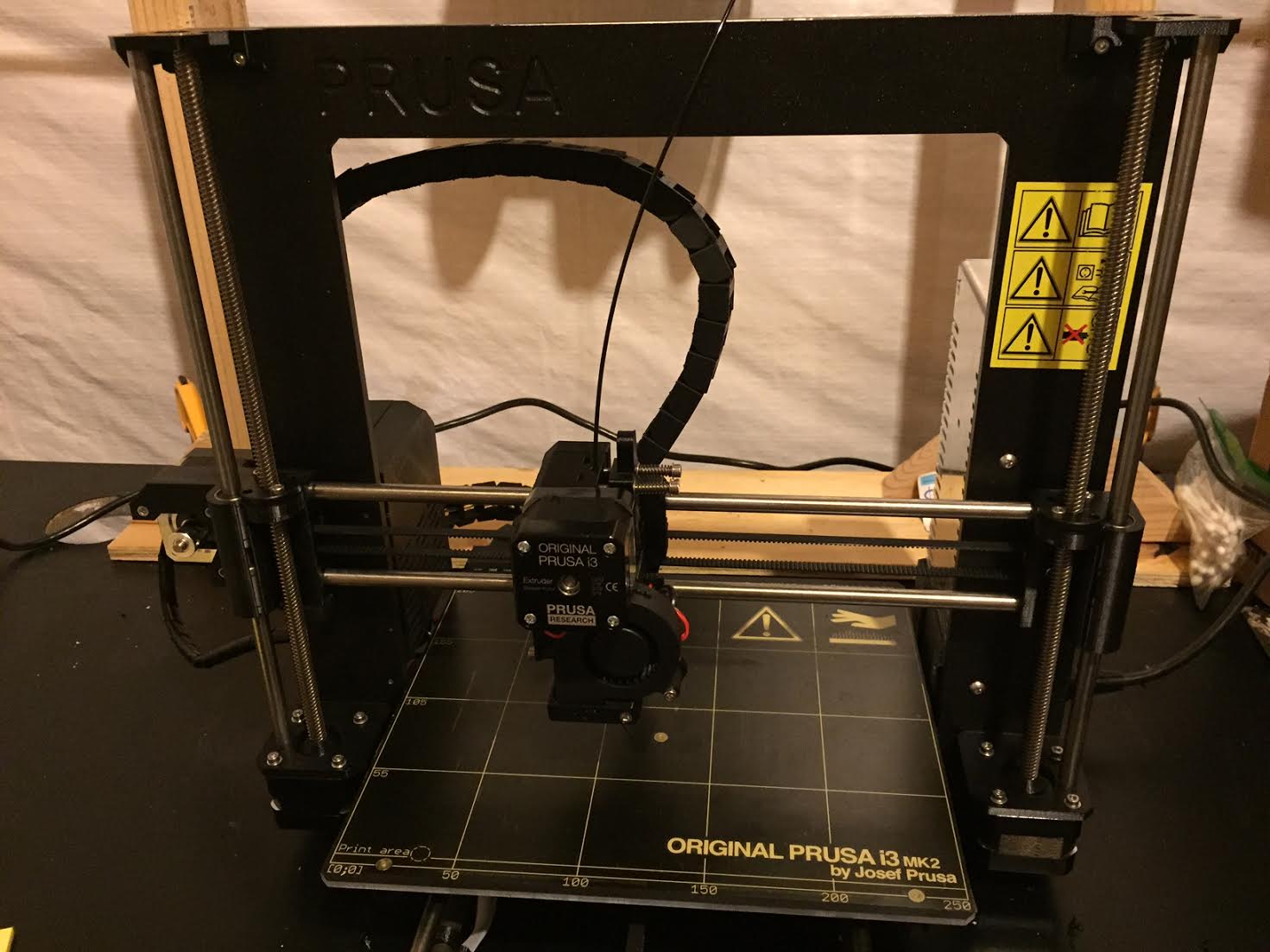

Mk2 cable chains

Hi all,

I prefer cable chains over cable wraps. I've posted my model on thingiverse.

http://www.thingiverse.com/thing:1725591

There is so little clearance from where the cables come out of the X carriage that I had to add a few links to allow my parts to rotate about the z axis to get space for the cable chain to connect. The "link" part is difficult to get the cables through, but it can be done without breaking. The heater cables will need the ends removed.

Cheers,

Tim

Re: Mk2 cable chains

Nice. Do you plan cable chain for X motor as well?

Re: Mk2 cable chains

I don't plan on it. The main reason I wanted to switch to the chains was to limit the motion of the cables to the same plane as the motion of the part they're going to. The x motor cables already do that with the cable wrap. I think I'll leave it as is, unless a bunch of people ask for it.

Re: Mk2 cable chains

Very nice I agree, and I think chains like this give printers a far more professional look, I hope Prusa consider changing over to them. I would be interested in you adding a x motor chain... Gotta have the full set after all! 😆

Looking at your images on Thingiverse, do we have to print a new x-carriage as well? 😕

Re: Mk2 cable chains

I remade someone's Thingaverse chain link (parametric) so that it could snap together rather than having to feed the wires through it. I find that this is a much better design:

https://tinkercad.com/things/62oO07P1cjl

Thanks Tim for the models! I hope you don't mind that I'll be modifying them a little bit. I do like your pictures, but I find a couple of them a bit dark and hard to find some of the details on.

As for the extruder motor cable chain; I still haven't worked out the exact details yet, but I believe that I'll have to make a special cable chain link that swivels in order to account for the up/down and left/right movement. I do really hate that the extruder motor cable tends to rub across my prints and print bed.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

Very nice I agree, and I think chains like this give printers a far more professional look, I hope Prusa consider changing over to them. I would be interested in you adding a x motor chain... Gotta have the full set after all! 😆

Looking at your images on Thingiverse, do we have to print a new x-carriage as well? 😕

No, there is no need to print the x-carriage. That was just in for illustration of how those parts go together.

I doubt Prusa would change over. Printing the chains can be very time intensive and the cable wrap is cheap/effective.

Re: Mk2 cable chains

I remade someone's Thingaverse chain link (parametric) so that it could snap together rather than having to feed the wires through it. I find that this is a much better design:

https://tinkercad.com/things/62oO07P1cjl

Thanks Tim for the models! I hope you don't mind that I'll be modifying them a little bit. I do like your pictures, but I find a couple of them a bit dark and hard to find some of the details on.

As for the extruder motor cable chain; I still haven't worked out the exact details yet, but I believe that I'll have to make a special cable chain link that swivels in order to account for the up/down and left/right movement. I do really hate that the extruder motor cable tends to rub across my prints and print bed.

Of course I wouldn't mind mods. That's the whole point of sharing! 😉

You're spot on about the lighting. I like the all black printer and it does make it difficult to get good contrast. I think most people can generally see what I'm trying to accomplish.

Have you printed those snap together links? The feature size is so small, I wonder how effective they are. Routing the cables didn't take all that long.

Re: Mk2 cable chains

Very nice I agree, and I think chains like this give printers a far more professional look, I hope Prusa consider changing over to them. I would be interested in you adding a x motor chain... Gotta have the full set after all! 😆

Looking at your images on Thingiverse, do we have to print a new x-carriage as well? 😕

No, there is no need to print the x-carriage. That was just in for illustration of how those parts go together.[/quote]

Ok, thanks...

I doubt Prusa would change over. Printing the chains can be very time intensive and the cable wrap is cheap/effective.

Oh they can just add half a dozen more printers to their Print Farm... they'll hardly notice the difference! 😈 😆 😆

Re: Mk2 cable chains

I remade someone's Thingaverse chain link (parametric) so that it could snap together rather than having to feed the wires through it. I find that this is a much better design:

https://tinkercad.com/things/62oO07P1cjl

Thanks Tim for the models! I hope you don't mind that I'll be modifying them a little bit. I do like your pictures, but I find a couple of them a bit dark and hard to find some of the details on.

As for the extruder motor cable chain; I still haven't worked out the exact details yet, but I believe that I'll have to make a special cable chain link that swivels in order to account for the up/down and left/right movement. I do really hate that the extruder motor cable tends to rub across my prints and print bed.

Of course I wouldn't mind mods. That's the whole point of sharing! 😉

You're spot on about the lighting. I like the all black printer and it does make it difficult to get good contrast. I think most people can generally see what I'm trying to accomplish.

For the first photo, no issue. For the next 2, a small light on the right hand side of the photo would have helped.

Have you printed those snap together links? The feature size is so small, I wonder how effective they are. Routing the cables didn't take all that long.

Yeah, the snaps are quite fine detail in that particular chain link. I was going to change to a 0.2 nozzle to print that, but since you came up with something decent I think I'll abort. I think with yours, I'm going to make the snap wrap around the outside of the link instead of inside like this one.

How many of each chain link do we need to print? How many for the first chain, and how many for the 2nd?

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

Of course I wouldn't mind mods. That's the whole point of sharing! 😉

Well then, here are my mods. I've edited every single STL on Thingiverse. Tim Saucer, if you want to use these on your Thingiverse site, go ahead.

I did find a few non-manifold bits to the Rambo case that I fixed. I also strengthened up the Heatbed Cover chain link. I am not an engineer, but I do have a mechanical mind.

One word of warning: Currently, all parts have very tight tolerances. I have yet to print and test these but I will in the coming days and make revisions as needed to fix tolerances. All chain links have an open end and can be closed by the appropriate cover included in the respective STL. I've done what I can to make everything either snap together or press fit depending on where the chain link stress is going to be greatest. I've done what I can to lay the parts out so they lay on the print bed in the correct orientation for strength and minimal supports.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

I did find a few non-manifold bits to the Rambo case that I fixed. I also strengthened up the Heatbed Cover chain link. I am not an engineer, but I do have a mechanical mind.

Thanks. I didn't notice the manifold errors. I've updated & uploaded a corrected version. Good luck with your mods.

Re: Mk2 cable chains

You're spot on about the lighting. I like the all black printer and it does make it difficult to get good contrast. I think most people can generally see what I'm trying to accomplish.

For the first photo, no issue. For the next 2, a small light on the right hand side of the photo would have helped.

How many of each chain link do we need to print? How many for the first chain, and how many for the 2nd?

I've posted a couple of additional photos.

I used 26 regular links + 1 full rotation link for chain to the x carriage and 13 regular + 1 full rotation for the heatbed. Depending on how tight you are comfortable with the cables inside the rambo housing you may be able to fix more, but I found this gives full range of motion.

Re: Mk2 cable chains

As I'm interested in using cable chains, I went ahead and printed out those X-Carriage Chain Link snaps and got them to fit on my X-Carriage. I noticed that after I attached the top snap, I can no longer move the Z axis to its max at the top endstops. This also means I would be unable to recalibrate my X/Y axis skew. I did notice that if I were to go ahead and try to use Cable chains, I'd have to remake the X-Carriage so that the top chain link snap is integrated into the X-Carriage, but have the divet pointing down instead of up. There just isn't enough clearance otherwise. Also, I did notice the X-Carriage STL file from Prusa is damaged so that means I have yet another STL to remake in TinkerCAD.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

Due to the clearance issues I noted above, I went ahead and remade the X-Carriage, Wide Cable Chain Link, X-Carriage Turn Link, and X-Carriage Chain Link snaps. Each object is a separate shell. If you copy the design into your own TinkerCAD account, you can download the separate STL models.

I've also removed the above models that were available separately.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

As I'm interested in using cable chains, I went ahead and printed out those X-Carriage Chain Link snaps and got them to fit on my X-Carriage. I noticed that after I attached the top snap, I can no longer move the Z axis to its max at the top endstops. This also means I would be unable to recalibrate my X/Y axis skew. I did notice that if I were to go ahead and try to use Cable chains, I'd have to remake the X-Carriage so that the top chain link snap is integrated into the X-Carriage, but have the divet pointing down instead of up. There just isn't enough clearance otherwise. Also, I did notice the X-Carriage STL file from Prusa is damaged so that means I have yet another STL to remake in TinkerCAD.

That's annoying. Thank you, I noticed it before. If you're going through the trouble of reprinting the x carriage, you could do something that would eliminate the clearance issue altogether and run the cable chains along the front of the printer, similar to http://www.thingiverse.com/thing:57533

I was hoping to avoid reprinting the x carriage to make the mod as close to stock as possible. I think I may just make an L type bracket by the zip tie part so I can stick with my original scheme.

Re: Mk2 cable chains

Hi everyone,

Thank you for all the suggestions. I've come up with a much simpler way to mount the parts on the back of the x carriage. No more link parts - just taking advantage of the material to bend slightly. The deflection isn't enough to cause damage and this requires no modification to the x carriage itself.

Re: Mk2 cable chains

Thanks for those updates. I did find that EL useful and have implemented the full cable chain (with open snap links) on my printer. It is great, but there are a couple of issues I discovered with the Rambo housing. The USB port is slightly obstructed and the other half of the Rambo housing doesn't fit into the reprinted half.

I rebuilt it. You can get my modified Rambo housing here.

I'm also concerned that the EL on the back of the X-Carriage will cause problems with the Quad extruder upgrade.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

I've modified the original poster's X-Carriage Chain EL so that you can have spool holders and possibly the Quad Extruder upgrade. If the quad extruders get in the way once I get my set, I'll update the model so that the interference is gone.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Mk2 cable chains

Thanks for making this! ive been looking for a good cable chain design for the MK2 😀

I was actually working on one till i found this .. its perfect!

Re: Mk2 cable chains

You will probably want to look over mine (at the end of page 1) with the snap clips to make it so you don't have to thread wires through each link.

and an 8 inch (200mm) or greater caliper is recommended.