Re: Mini-Rambo 1.3 and e3d with PT100

need some help .

once i remove the "//" from "//#define E3D_PT100_EXTRUDER_WITH_AMP" does the max extruder temp settings also changes ? or do i need to change different config to set max temp higher .

if it does change , what is the max temp once i set this config ?

can i then choose higher preheat temps from settings menu on the printer ?

i already have pt100 , amp , 40w heater and copper block .

Re: Mini-Rambo 1.3 and e3d with PT100

Hi guys,

Thanks for all the informations you have sheared here!

I have a Prusa mk2 with a mini rambo 13a and i am trying to install a PT100 with the E3D amplifier .... but somehow it does not work at all... i get at RT something like 100°C...

I connected the amplifier like it was shown here, but i most likely have a firmware problem. Can someone tell me what i have to change in the firmware ?

i guess it is about the pins but i have no idea ://

Re: Mini-Rambo 1.3 and e3d with PT100

need some help .

once i remove the "//" from "//#define E3D_PT100_EXTRUDER_WITH_AMP" does the max extruder temp settings also changes ? or do i need to change different config to set max temp higher .

if it does change , what is the max temp once i set this config ?

can i then choose higher preheat temps from settings menu on the printer ?

i already have pt100 , amp , 40w heater and copper block .

I too was worried about this and did some digging in the config file while i was setting up my PT100.

By un-commenting the "//#define E3D_PT100_EXTRUDER_WITH_AMP"

you raise the maxtemp to 410C° Which I think is probably accurate to the actual specs of the sensor.

Unfortunately though, i dont think you can choose higher preheat temps on your settings menu, that might require some more extensive firmware modification on your end.

Hi guys,

Thanks for all the informations you have sheared here!

I have a Prusa mk2 with a mini rambo 13a and i am trying to install a PT100 with the E3D amplifier .... but somehow it does not work at all... i get at RT something like 100°C...

I connected the amplifier like it was shown here, but i most likely have a firmware problem. Can someone tell me what i have to change in the firmware ?

i guess it is about the pins but i have no idea ://

I've had pretty much exactly that same problem, so i tested to see if it would work without the amplifier, and with the appropriate option un-commented "something somthing pt100 no amplifier something something" i got it to work on a basic level. I have yet to test it with any PC or other high temp materials because it tends to jump between temperatures quite easily, occasionally triggering thermal runaway. I have considered but have not yet pulled the trigger on that particular firmware modification.

Re: Mini-Rambo 1.3 and e3d with PT100

works great with the amp . all you have to do is to remove the "//" from "//#define E3D_PT100_EXTRUDER_WITH_AMP" in configuration file .

the max temp updates automatically

Re: Mini-Rambo 1.3 and e3d with PT100

I've been working on getting this to work (without an amp). I actually bought the pt100 by accident, thought I was getting the stock thermistor. Some things I found:

1) There is a typo in the 3.5.0 version of the firmware. See thermistortables.h line 1094:

{30.00000 * OVERSAMPLENR,140},

{35.50000 * OVERSAMPLENR,150},

{31.00000 * OVERSAMPLENR,155},

That 35.5 should likely be 30.5. This causes the measured temp to stall at 150 until it hits 215 and then it jumps. I plotted the table with it set to 30.5 and it looks more reasonable.

2) The table seems to be made based on a bunch of measurements vs. doing a curve fit of measurements. So the curve is very much not smooth, which I think adds noise and jumpiness. I did a polynomial curve fit of the data and re-generated the table. The fit gives an R^2 value of 99.6% so it fits the data quite well yet is smooth. Here's the table.

{ 18.824 * OVERSAMPLENR, 0 },

{ 19.2301 * OVERSAMPLENR, 5 },

{ 19.6362 * OVERSAMPLENR, 10 },

{ 20.0423 * OVERSAMPLENR, 15 },

{ 20.4484 * OVERSAMPLENR, 20 },

{ 20.8545 * OVERSAMPLENR, 25 },

{ 21.6667 * OVERSAMPLENR, 35 },

{ 22.0728 * OVERSAMPLENR, 40 },

{ 22.885 * OVERSAMPLENR, 50 },

{ 23.6972 * OVERSAMPLENR, 60 },

{ 24.1033 * OVERSAMPLENR, 65 },

{ 24.5094 * OVERSAMPLENR, 70 },

{ 24.9155 * OVERSAMPLENR, 75 },

{ 25.7277 * OVERSAMPLENR, 85 },

{ 26.1338 * OVERSAMPLENR, 90 },

{ 26.946 * OVERSAMPLENR, 100 },

{ 27.3521 * OVERSAMPLENR, 105 },

{ 27.7582 * OVERSAMPLENR, 110 },

{ 28.1643 * OVERSAMPLENR, 115 },

{ 28.9765 * OVERSAMPLENR, 125 },

{ 29.7887 * OVERSAMPLENR, 135 },

{ 30.1948 * OVERSAMPLENR, 140 },

{ 31.007 * OVERSAMPLENR, 150 },

{ 31.4131 * OVERSAMPLENR, 155 },

{ 32.2253 * OVERSAMPLENR, 165 },

{ 33.0375 * OVERSAMPLENR, 175 },

{ 33.4436 * OVERSAMPLENR, 180 },

{ 34.2558 * OVERSAMPLENR, 190 },

{ 34.6619 * OVERSAMPLENR, 195 },

{ 35.4741 * OVERSAMPLENR, 205 },

{ 36.2863 * OVERSAMPLENR, 215 },

{ 36.6924 * OVERSAMPLENR, 220 },

{ 37.5046 * OVERSAMPLENR, 230 },

{ 37.9107 * OVERSAMPLENR, 235 },

{ 38.7229 * OVERSAMPLENR, 245 },

{ 39.129 * OVERSAMPLENR, 250 },

{ 39.5351 * OVERSAMPLENR, 255 },

{ 39.9412 * OVERSAMPLENR, 260 },

{ 41.1595 * OVERSAMPLENR, 275 },

{ 41.9717 * OVERSAMPLENR, 285 },

{ 42.3778 * OVERSAMPLENR, 290 },

{ 43.19 * OVERSAMPLENR, 300 },

{ 43.5961 * OVERSAMPLENR, 305 },

{ 44.4083 * OVERSAMPLENR, 315 },

{ 45.2205 * OVERSAMPLENR, 325 },

{ 45.6266 * OVERSAMPLENR, 330 },

{ 46.4388 * OVERSAMPLENR, 340 },

{ 46.8449 * OVERSAMPLENR, 345 },

{ 47.6571 * OVERSAMPLENR, 355 },

{ 48.0632 * OVERSAMPLENR, 360 },

{ 48.8754 * OVERSAMPLENR, 370 },

{ 49.2815 * OVERSAMPLENR, 375 },

{ 50.0937 * OVERSAMPLENR, 385 },

{ 50.4998 * OVERSAMPLENR, 390 },

{ 51.312 * OVERSAMPLENR, 400 },

{ 51.7181 * OVERSAMPLENR, 405 },

};

3) With this things worked much better, but it still could get a thermal runaway. I think due to the low resolution without the amp, the signal is just noisy. Looking at the PID code, I saw that the PID stays off until you get to within PID_FUNCTIONAL_RANGE (line 134 in Configuration.h), which is defaulted to 10 degrees. So the PID stays off until it gets to within 10 degrees. With the noise in the readings, it's very easy to fall back out of 10 degrees (the I term doesn't have enough time to kick in), which then turns the PID back off and resets it. So it can bounce back and forth and hang out 10-20 degrees off, which then gives the thermal runaway . So I changed PID_FUNCTIONAL_RANGE to 30 degrees, to give the PID a chance to work, and that has fixed the issue. It's still tough to get a smooth temp given the noise, but I can get it to stay within +-3-5 degrees. I set the P coefficient to 10.0 (this ensures max power output when you get within 30 degrees so that you don't out of the functional range, yet is a low value to prevent a lot of noise). I set I to 1.0, which seems to build up the iterm pretty rapidly but not too quick. Then the D term I have at 10-20. There is a lot of noise in the measurements, so it seems having a really high D term can amplify that noise.

I bought an amplifier, but again, bought the wrong thing. I got one that sends the data of SPI, rather than sending an analog signal (adafruit MAX31865). Seems like actually using spi would take a pretty big rewrite of the firmware, do probably will return it and get an analog one. Was trying to figure out though if I can tap into the analog signal somewhere on the board (the max31865 has an internal ADC converter, but not sure which pin it is converting, or if the analog signal is actually internal to the chip). If anyone has an idea on this let me know.

RE: Mini-Rambo 1.3 and e3d with PT100

It sounds like you guys found a solution here. I'm Planning on installing the PT100 on my printer arriving in a few days, Although I'm pretty sure ill eventually figure out how to connect the hardware properly, I'm completely cluless regarding the firmware & how to use the table mentioned above. Is there a pre-converted firmware that I can download somewhere that has this updated table?

-Steve

I've been working on testing the PT100 with an amplifier and without. The Amplifier definitely makes a big difference in the temperature resolution. I have submitted a pull request to have the PT100 information be merged into the main Prusa MK2 sources. I don't expect this to happen for quite awhile so you will probably have to patch the source code yourself.

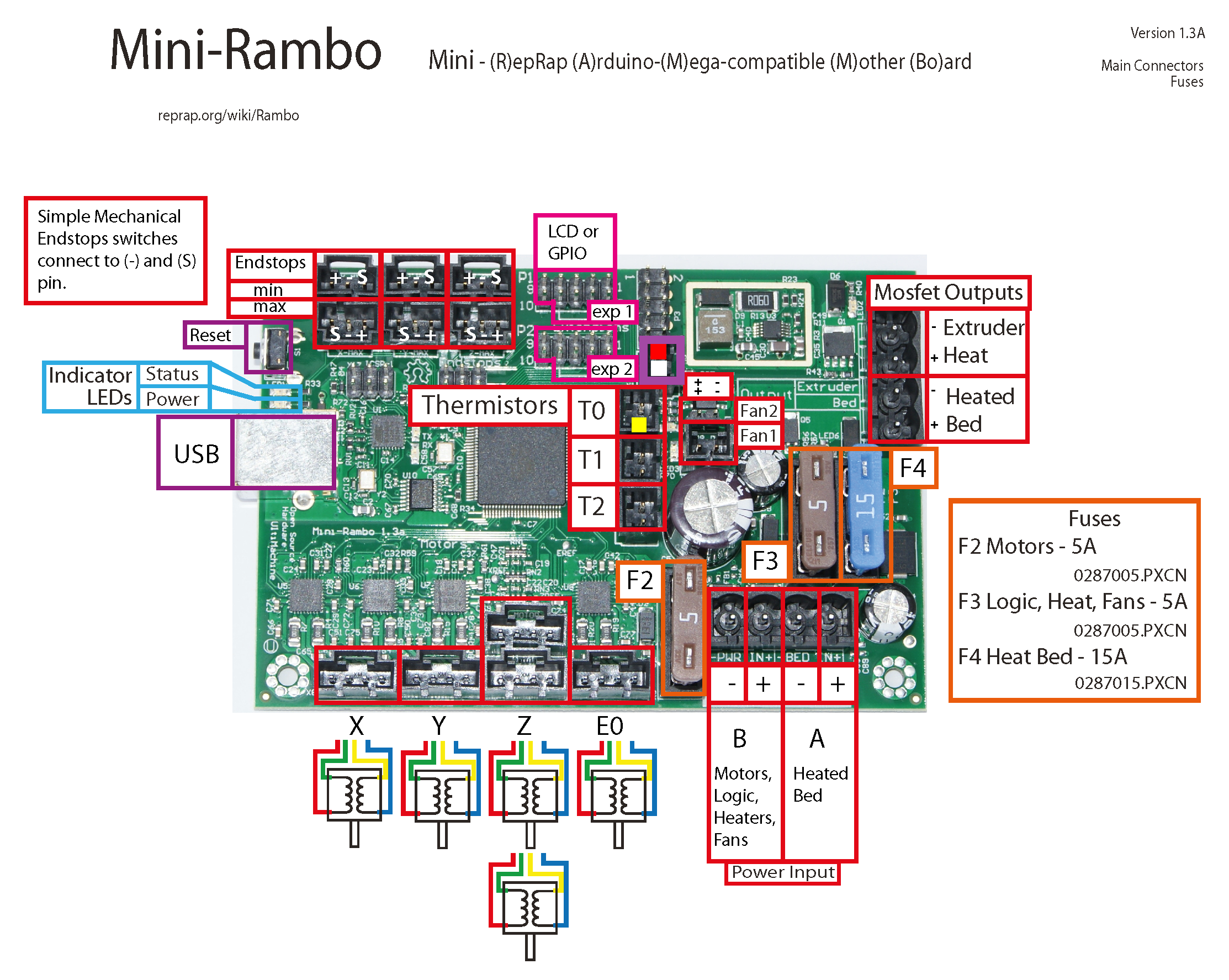

As for wiring it up, I'm going to refer to a picture that was posted in this forum some time back about this topic (with a few modifications):

In the purple rectangle, the Red square is for the Positive lead coming from the E3D PT100 amplifier, the white square is for the Negative lead, and the Yellow square near T0 is for the Signal lead.

You will also need a Female to Female DuPont connector similar to a 3-wire Sensor Cable but one end will need to have a single pin DuPont connector and a double pin DuPont connector (to match the picture above).

With this configuration and a 40W heater cartridge, I was able to get the hot end to 410C. I know that I wanted to, I could probably push that higher after modifying the firmware limits.

Hi all,

I need some help with this. I have the Prusa MK3S and I am trying to connect the 'Amplifier' of the PT100 to the EINSy board. I thought I could use the nice explanation that was made by @ayourk in the post above, because I'm not knowledgeable with electronics. However, while I think the yellow dot for the signal lead has stayed the same, the new Einsy board does not have the same layout for the P3 connector. There is only now only the 5x2 array of pins with the filament sensor at the bottom and possibly a MMU addition on top.

So I am wondering where to fetch the 0 and 5V pins on the new Einsy board. I found this reddit post that will probably be helpful for some, but I am at loss to find my info there...

On the attached image, I attempted something with the yellow square representing the signal lead, and the red square where the 5V lead could go. Is this correct? I also have no idea where the 0V can be fetched.

Could somebody help me out with this?

Thanks a lot!

RE: Mini-Rambo 1.3 and e3d with PT100

Hey, so after a bit more googling and reflection, I elaborated something that hopefully will be a more educated guess. Please ignore the first one as this was very stupid, but time for me to edit my previous post has expired... 😬

So yellow is the signal at left pin of T0, red is 5V at Pin 1 of the P3 array, and white is Pin 7 of the same array as shown on the attached image.

Can somebody have a look and confirm that this is the good way of plugging the PT100 Amplifier to the Einsy board?