Filament Spool Mount

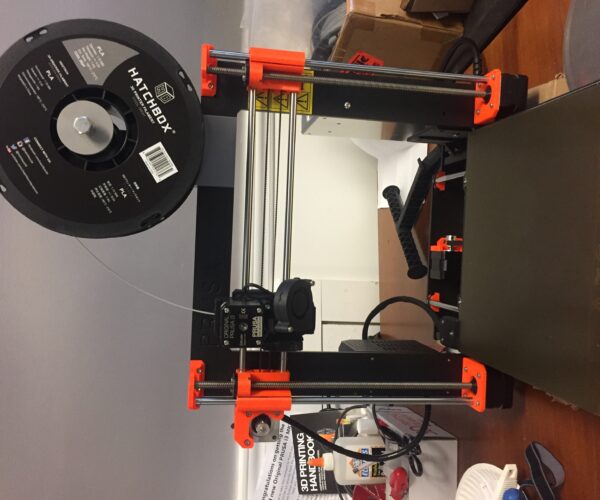

For quite sometime, I have watched my MK3 whip the filament around as the head jumps from place to place. The spool scrapes on the support bar and the filament frequently pulls against the side of the spool flange. There is no way this pulling, scraping and tugging cannot affect the accuracy of the print head, or cause a resonance that does the same thing.

It is an easy observation to see that the print head moves only in the XZ plane. X is fast motionand Z is slower motion. Orienting the spool parallel to the XZ plane would eliminate a lot of the whipping and scraping the side of the spool. A small, hard axle would lower the rotational scraping of the spool on the support bar.

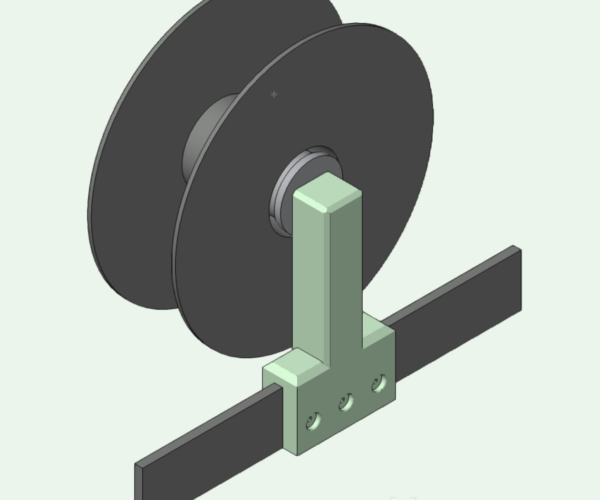

For an axle, I took a 3/8in x 5in bolt and made a hollow drum for it to rotate about. The Plastic drum rotating on the steel bolt is much less friction than the spool scraping on the bar. No need to go to a real ball bearing.

The support is an inverted tee shape that straddles the top of the printer frame, with screws on the back to tighten against the frame. The axle bolt screws into the leg of the tee. The support can be positioned anywhere along the top of the frame. I choose the filament to feed from about the center of the frame.

You can see it is working when the spool rotates forward and backward as the head moves, indicating low friction. The filament cannot scrape the side of the spool.