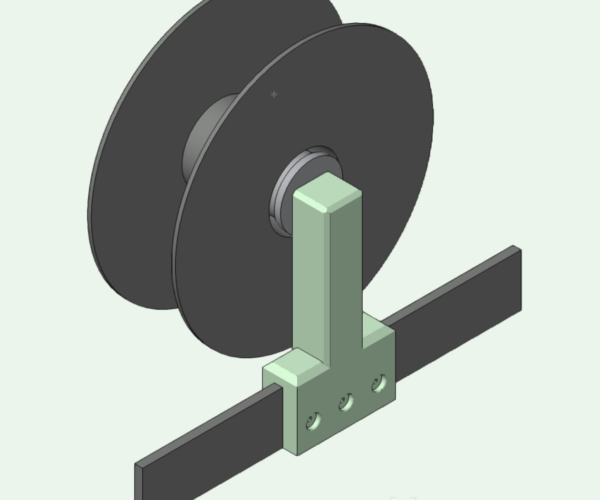

Filament Spool Mount

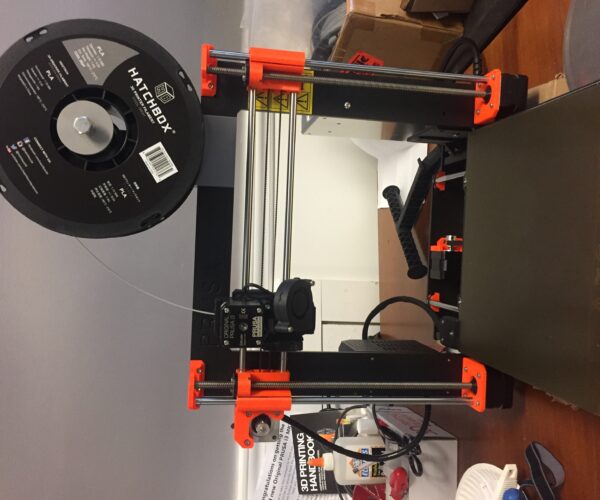

For quite sometime, I have watched my MK3 whip the filament around as the head jumps from place to place. The spool scrapes on the support bar and the filament frequently pulls against the side of the spool flange. There is no way this pulling, scraping and tugging cannot affect the accuracy of the print head, or cause a resonance that does the same thing.

It is an easy observation to see that the print head moves only in the XZ plane. X is fast motionand Z is slower motion. Orienting the spool parllel to the XZ plane would eliminate a lot of the whipping and scraping the side of the spool. A small, hard axle would lower the rotational scraping of the spool on the support bar.

For an axle, I took a 3/8in x 5in bolt and made a hollow drum for it to rotate about. The Plastic drum rotating on the steel bolt is much less friction than the spool scraping on the bar. No need to go to a real ball bearing.

The support is an inverted tee shape that straddles the top of the printer frame, with screws on the back to tighten against the frame. The axle bolt screws into the leg of the tee. The support can be positioned anywhere along the top of the frame. I choose the filament to feed from about the enter of the frame.

You can see it is working when the spool rotates forward and backward as the head moves, indicating low friction. The filament cannot scrape the side of the spool.

RE: Filament Spool Mount

I like the basic approach. Are you certain the Z axis can be moved to maximum height without the extruder colliding with the bracket?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Filament Spool Mount

The print head can collide at max height. The vertical leg is too wide and hits the motor.

I am thinking of several improvements that should solve all problems. There is plenty of space for a slimmed down clamping design.

Make the clamp action vertical, not horizontal. It could also copy the design of the standard clamp. This one also holds the spool too low, so that the print head could hit the spool. I printed in on my Lulzbot Mini because my MK3 was running, and it has a max Z of 6 inches. It needs 7.

It is also one piece, and needs to be several pieces for more flexible design and faster printing.

Lets see what V2 looks like.

RE: Filament Spool Mount

OK, version 2 seems to fix all errors. The front fingers need to be less than 3mm thick to clear the head, but that is enough to make a strong mount. 10-24 screws pull the pieces together and add some “backbone” to stiffen the bottom piece. I added 25mm to the height for the spool to clear the print head.

RE: Filament Spool Mount

With all the talk about moisture absorption in the filament, I decided to see if I could minimize it while my filament sits idle for long periods of time on the printer. I have been using 2 gallon zip bags to store my filament, with the dessicant in the bag that is shipped with the filament.

With the new spool holder parallel to the X axis, I decided to place a plastic bag over the spool when the unit is idle. It doesn’t seal, but it does cover the whole spool and some below. I figured it might help some (it is pouring rain right now).

Then I started another print and forgot to remove the bag. turns out it prints fine with the bag over its “head”. I am thinking of a more form fitting enclosure with a narrow slot for the filament to travel back and forth in to restrict the opening as much as possible. Maybe even a slide to close the slot when the printer is idle.