Re: Extruder fan specification ?

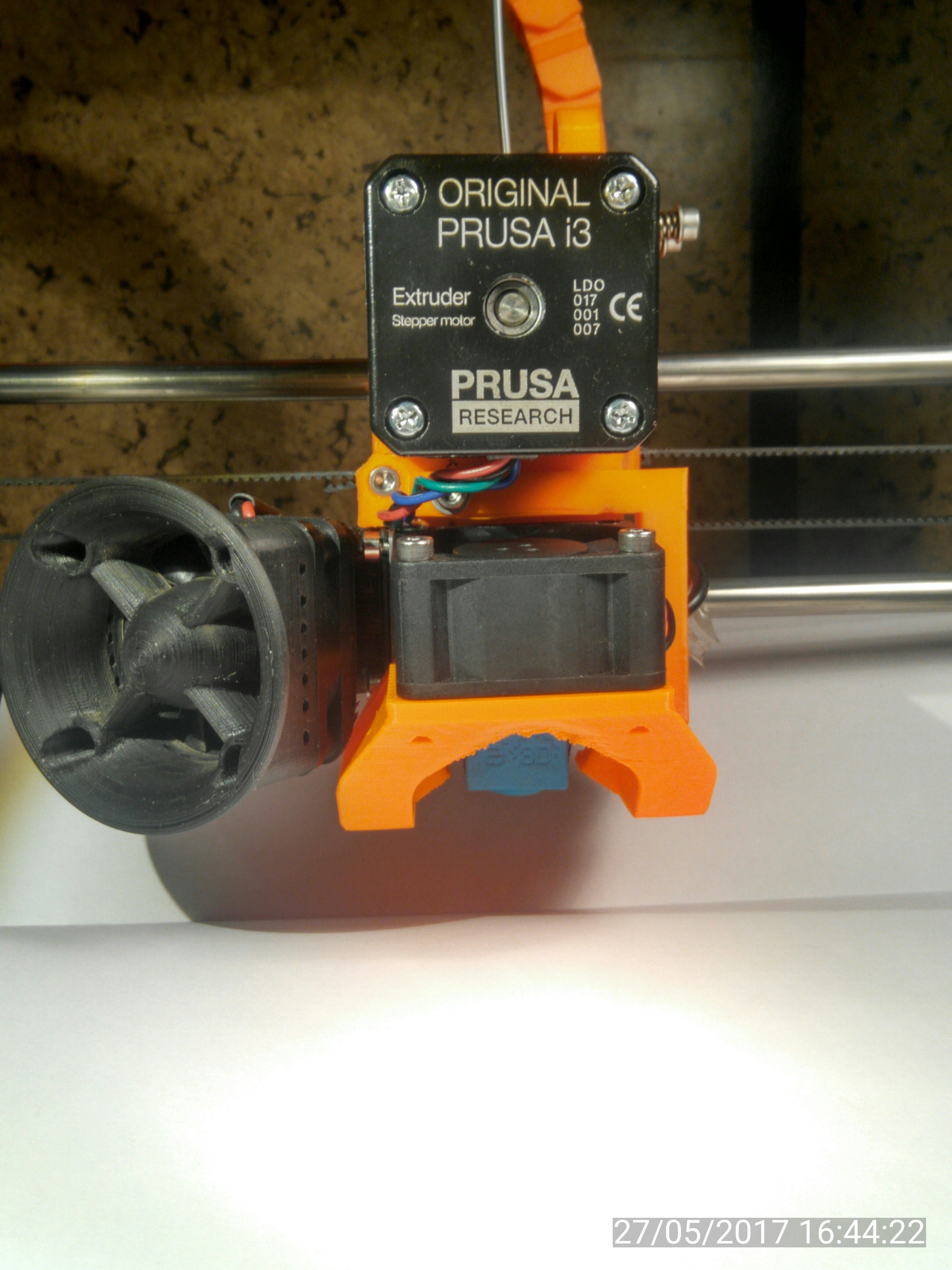

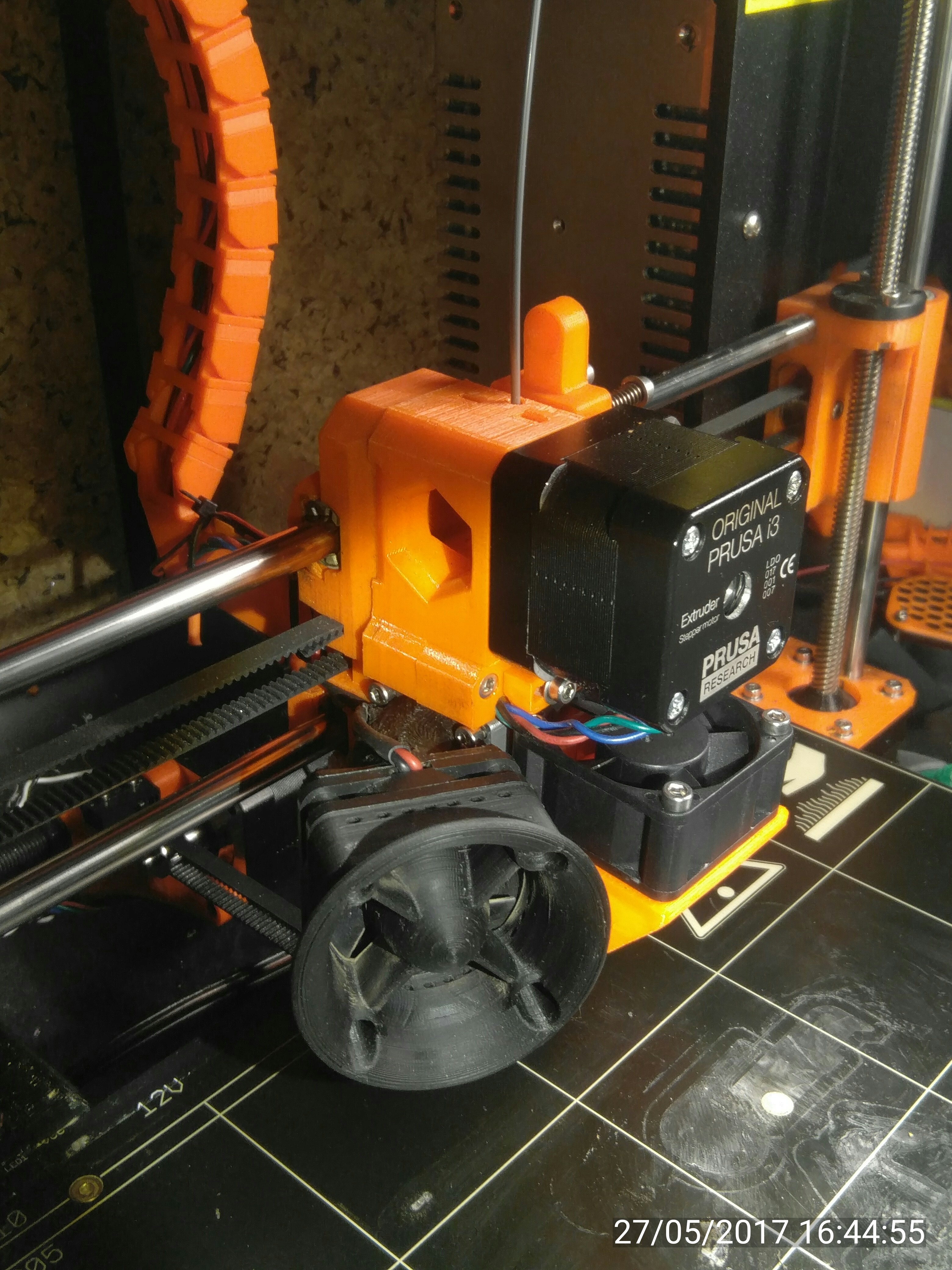

finished my fan mods both to the hotend cooling and the layer cooling fans. Now have near silent cooling on both. the layer fan is shifting almost 8cfm and cools both sides at once plus gives me a great view of the nozzle so I can see exactly whats going on with my print.

Re: Extruder fan specification ?

Yeah I tried a bunch of spool holders till I found this one https://www.thingiverse.com/thing:2122419 love the adjustable width and it's solidly on there but slides easily from side to side..printed in PLA with rollers in FPE and the gears in taulman bridge nylon.. the filament guide I'd have to search for the file I modded.. it was to fit a thicker printer so I remixed it to fit the prusa .. actually it could do with being a mm thinner still as it's not quite as solid a push on as I'd like..

Re: Extruder fan specification ?

I wish I had come across this thread before I did the Noctua fan mod on my printer. So far I havent had any issues but I have noticed that the cool down time is a little longer now.

So what fan would be recommended when using the Tilted adapter ( https://www.thingiverse.com/thing:2076234 ) ?

Re: Extruder fan specification ?

Has anyone tried sticking with the stock fan, but creating an adapter that has vanes? You'd need vanes that align perfectly with the fins on the heatsink.

You're not fighting a loud fan. You're fighting air hitting the edges of the heatsink right out of the fan.

Re: Extruder fan specification ?

finished my fan mods both to the hotend cooling and the layer cooling fans. Now have near silent cooling on both. the layer fan is shifting almost 8cfm and cools both sides at once plus gives me a great view of the nozzle so I can see exactly whats going on with my print.

IMG_20170527_164422.jpegIMG_20170527_164455.jpegIMG_20170527_164445.jpeg

Hi to all

I this part cooling fan available for download?

Best regards to all

Re: Extruder fan specification ?

Hi gary.h2.

What is your experience with the new extruder body, specially with the fan duct for the parts cooling ? Did you see any improvements on the printed parts ?

I'm asking because I have developed nearly the same extruder body.

Thomas

Re: Extruder fan specification ?

Hi Thomas.. I think I'm getting better results with PLA for sure with the cooling from both sides, a number of my earlier prints had a definite "side" that was smoother and better finished , no sagging etc. I've not been able to test as exhaustively as I'd like as i had major spinal surgery which has put a bit of a crimp in my playtime on the printer for last 2 months, but I'm also delighted to be able to actually SEE the nozzle as it prints, now , if there IS a problem , first layer not sticking , whatever, I can spot it instantly instead of the having to try and get my head level with the bed and squint under the original fan housing and duct, frankly I'd fit this mod again just for that.. Once I can sit in a chair without pain for more than 20min I'll try some more extreme bridging and overhang prints just to see how far I can push things before I get sag..

love a link to anything similar you've developed

and luis look here https://www.thingiverse.com/thing:2297721 I think I put all the details of what I did there

Re: Extruder fan specification ?

I have been following this thread for a long time, and have been interested in upgrading my cooling fan. Sound level was not my interest, but rather the amount of cooling provided, and in particular, how to keep the heat break cooler.

So, I have just done an experiment which I would like to share with you. (I am very pleased with the results so far).

Original E3D fan is XYJ12B3010H, it has 4.08 CFM and 4.82 mmH2O static pressure. 4.82mm = 0.19 in

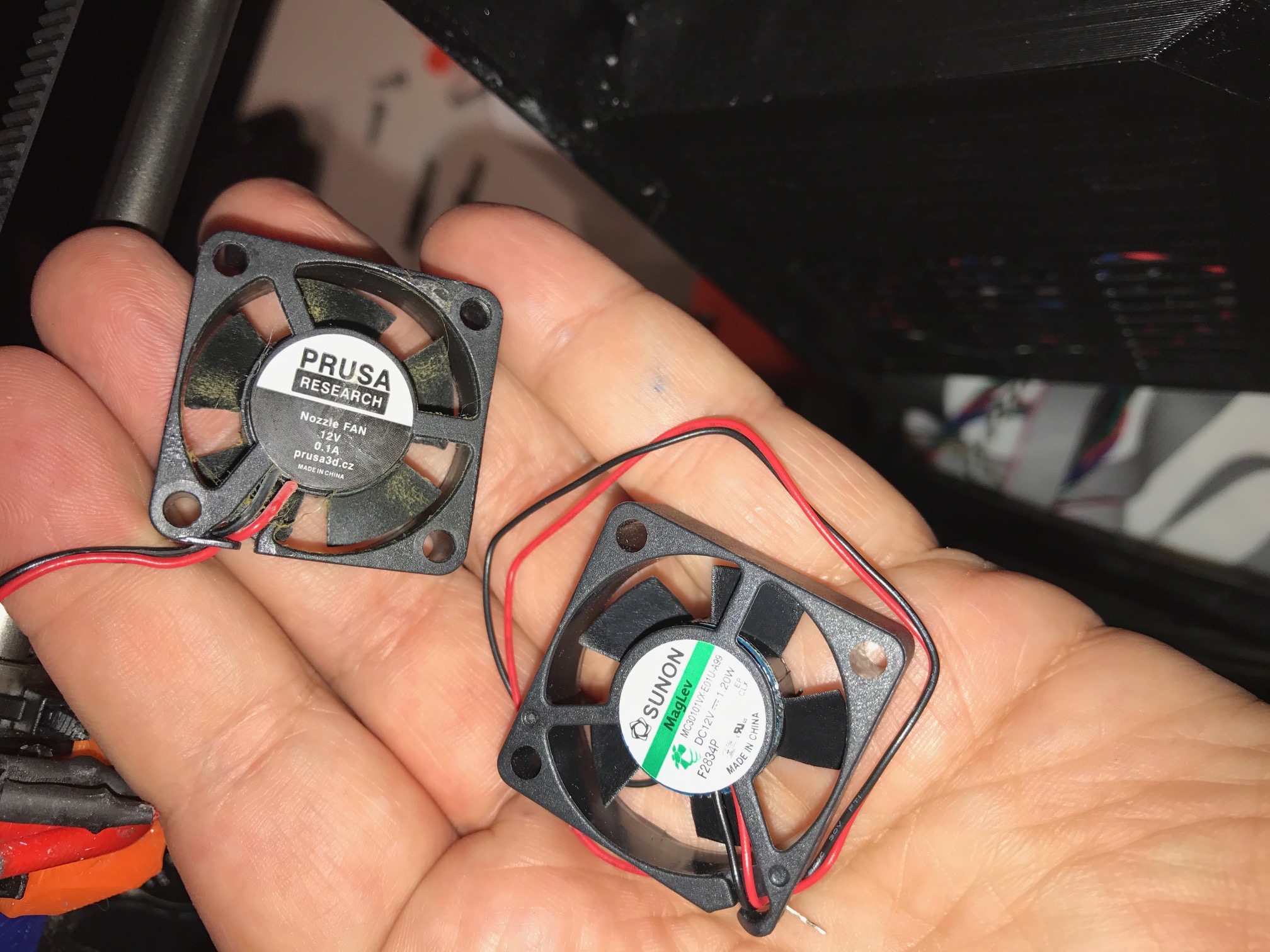

New Replacement: Sunon MC30101VX-E01U-A99 fan (Maglev)

6.0CFM and 0.230 in H2O

47% higher CFM and 21% more static pressure.

https://www.digikey.com/product-detail/en/sunon-fans/MC30101VX-E01U-A99/259-1661-ND/4835586

This fits the machine with no modification, but at least in the specs should provide more air flow and more static pressure.

To test this, I tested the sound level at the machine in a silent room with a phone app. Then tested the cool down time from 220C to 150, 100, 50.

Then I replaced the fan with the Sunon, and repeated these measurements.

The theory is that the faster it cools down, the more cooling is provided at the fins.

THEN, I added a small piece of ceramic insulation between the hot end and the heat break. And again repeated the measurements.

https://www.amazon.com/gp/product/B0725WLM1N/ref=oh_aui_detailpage_o00_s01?ie=UTF8&psc=1

I now expect it to take LONGER to cool down, because the insulation is keeping the heat in the hot end, but in theory, the heat break should remain cooler in this configuration at printing temperatures.

In all cases the hot end had a silicone sock on it.

Results:

Original fan: 55dB Sound, 220 -150C 1:30 100C 3:03 50C 6:38

Sunon fan: 55dB Sound, 220-150C 1:15 100C 2:36 50C 5:27

Sunon w ins: 55dB Sound, 220-150C 1:24 100C 2:57 50C 6:09

Conclusion:

The Sunon fan does increase cooling significantly, at no noticeable sound difference.

The insulation does keep heat in the hotend longer - thus I think the heartbreak will be cooler.

Thus, I think I am very happy with this modification to the printer.

The proof will be after printing for a while, but I will let you all know.

Sorry for the poor quality photos.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Extruder fan specification ?

I went with the relatively new Noctua 40x20mm fan for the heat break cooling. http://noctua.at/en/nf-a4x20-flx I used the same adapter model posted here. I didn't keep track of what size screws I used. I ordered an assortment off of amazon a while back (good investment).

So far it's working very well. Specs are better than the stock one. It's not totally silent like the 40x10mm version, but quiet enough that you can't hear it over the rest of the printer. Probably couldn't hear it across the room if it was the only thing on.

Regarding the Sunon fan, 25 years in the computer industry has made me quite wary of them. Performance is good when they work, but they seem to fail frequently, and are noisy. Reliability probably isn't a huge issue though, as it's right there where you can keep an eye on it and easily change it.

P.S. I like the insulation idea. I wonder how long before it will be included standard on hotends?

Re: Extruder fan specification ?

Regarding the Sunon fan, 25 years in the computer industry has made me quite wary of them. Performance is good when they work, but they seem to fail frequently, and are noisy. Reliability probably isn't a huge issue though, as it's right there where you can keep an eye on it and easily change it.

P.S. I like the insulation idea. I wonder how long before it will be included standard on hotends?

I had seen your warning before, so I bought two. 😀

So far, I am very pleased with both modifications.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Extruder fan specification ?

Did anyone notice a smell when hotend is hot, after the upgrade to Noctua 40mm fan ?

Either something with hotend(too much temp?) or titled adapter printed in PLA(should not be too much temp)

Re: Extruder fan specification ?

Gary, nice work, I've been searching for a solution for this one. Side benefit is cooling the extruder motor 😉

I'm been working on a push-pull based on Noctua NF-A4x10 because of concerns of weak pressure, but maybe I can just get to NF-A4x20 and do your setup instead.

MK2S kit owner since 8/15/2017

Re: Extruder fan specification ?

While everyone is testing cool down time, i've probed the temp of the heatsink. At 260c on the noctura 40x10mm it maintains at 36-37c, never goes higher. Room temp is 23c. at 200c it's 32-33c. Without a fan it gets 100c+ rather quick. i didn't test how hot it can get though.

This is well below the glass transition temp of PLA and much below that of materials that need to get up to 260c+ (ABS, PET, PC). Course getting a probe inside the hotend before the heatbreak would be ideal. the ptfe probably acts as a heat insulator as well so it might be as cool. no idea.

The A4x20mm (40x20mm) might be best at minimum for a quiet fan. Otherwise i would just run a light tube/hose with a larger remote blower someplace else. done this on my other printer in a heat chamber. though it has an exhaust hose too.

Chapeau !!

To sleep well, I placed a printer in the garage under our house. But now our neightbour became very irritated by the noise produced and glued a letter on our door. This rendered the printer as useless.

The kind service people at Prusa made me aware of the [silent mode] - and that helped quite a bit! But still too much noise!

Read about the noctua fan and got myself one. The printer seems working fine with it but to be on the safe side I'll get the beefier (and more silent) NF-A4x20-FLX.

Reducing the mechanical sound-levels has been done by using rubber washing-machine-noise damping pads with a slice of 60KG stone in between.

Works great! Noice down to 42DB. The material cooling fan I shall replace with a noctua too.

Here a silent setup:

Re: Extruder fan specification ?

Coming into this thread a bit late. What is the issue with the noctua 40x10? Is it that you can damage the printer because it lacks sufficient airflow?

Re: Extruder fan specification ?

Not exactly, it has to do with fan type needed. The NF-A4x10 is a flow optimized fan vs. what is more appropriate, a pressure optimized fan. If you have assembled your own PC tower, you know why this is something to consider when watercooling for instance. Like that situation, pushing air through the heatbreak is basically a radiator. NF-A4x20 is on the other hand a pressure optimized fan design, but heavier and louder. It also requires a bit more care finding the right adapter to clear X-axis range of motion. Concerning is the use of NF-A4x10 on MK3 prototypes, hopefully Prusa Research have used the extra volume of the MK3 design to open airway better suited to flow style fans as it will do the same job if flow is not restricted, impossible with MK2's extruder-body and extruder-cover part design. In short, NF-A4x20 is recommended if going for +6 hrs high temperature prints, if only PLA or other low temp filaments, NF-A4x10 has been reported as being adequate. For me, ABS only in an enclosure, I had melting on the stock nozzle assembly after a week of swap to NF-A4x10. So I designed a whole new head, nozzle and stronger break duct adapter and have had no thermal runnaways or melted body parts, nozzles were a different story. I'm still trying to design one that doensn't melt after 48 hrs ABS prints in a +40°C enclosure.

MK2S kit owner since 8/15/2017

Re: Extruder fan specification ?

I know this is off topic but in case anyone else planned to go with NF-A4x20 FLX for part cooler as well, my findings may be helpful.

Slight discouraging notes on Noctua NF-A4x20 FLX (12V) used as part cooling fan replacement. Unlike most centrifugal fans (aka blower) axial fans have a high power cold start. Example, stock blower starts as low as 10% fan speed or 25 hex, an after market cheap fan such as Sheng Feng needs 30% or 76 hex to kick over at all. The Noctua NF-A4x20 FLX requires at least 61% or 155 hex or more likely 62% 160 hex to be safe to actually do anything.

What does this mean?

Two things are effected. Thermal Runaway chances and high temp printer melting.

Stock MK2S running in a moderate climate ~24°C can suffer Thermal Runaway when running part fan too high for given print temperature. I've created a rough chart for myself.

Hot-end Fan Max Hex

200°C 100% 255

210°C 85% 217

220°C 70% 178

230°C 55% 140

240°C 40% 102

250°C 25% 64

260°C 10% 25

Sorry about the janky table, PR doesn't seem to have BBCode table on.

So based on this very conservative Thermal Runaway avoidance chart and with Noctua A4x20's kickover being 62%, safe max temp is roughly 225°C or PLA only. With an enclosure and block sock, you can add about 20°C to the chart or ABS, PETG, maybe Nylon.

And the reason why you need some fan is not necessarily for the printing part, but because the MK2/S (and likely MK3) is based printed ABS extruder assembly parts which has glass of 100°C. If you don't run fan at all while printing ABS itself, PC, Nylon, or PETG, etc., you run the risk of melting your printer down. Unfortunately, the Noctua NF-A4x20 FLX with a kickover of 62% will warp any temp delta sensitive filament, in my case ABS. So the Noctua's 20mm FLX is no go for me unless I can design a Curent Mode to PWM adapter.

MK2S kit owner since 8/15/2017

Re: Extruder fan specification ?

So on the other thread someone mentioned sucking instead of blowing for the x10 version and I decided since I had one I wasn't using lets give it a shot so I set the temps to 250 and then marked the time every 25 degrees. This may not be the most scientific test of how well a fan is going to prevent run away but it gives us a good idea how well they overall cool. I have two more fans on order I want to try. In addition I tried these stator vanes someone mentioned earlier in the thread from Pinshape. Those results are here as well.

Tempature E3D Fan Blow

250 00:00.0

225 00:24.4

200 00:53.1

175 01:27.9

150 02:10.2

125 03:00.7

100 04:08.2

75 05:45.0

50 08:23.2

Tempature Noctua Fan Blow

250 00:00.0

225 00:31.8

200 01:07.2

175 01:51.3

150 02:41.1

125 03:47.1

100 05:12.3

75 07:17.0

50 10:38.6

Tempature Noctua Fan Suck

250 00:00.0

225 00:31.9

200 01:06.2

175 01:50.1

150 02:43.0

125 03:48.9

100 05:13.5

75 07:12.4

50 10:31.5

Tempature Stator Vanes

250 00:00.0

225 00:34.9

200 01:11.0

175 01:55.5

150 02:47.4

125 03:52.4

100 05:17.6

75 07:21.3

50 10:41.0

Tempature Air Only

250 00:00.0

225 00:32.1

200 01:10.4

175 01:58.6

150 02:56.5

125 04:12.6

100 06:00.2

75 08:46.5

50 14:24.2

Re: Extruder fan specification ?

@Paul

Thanks for the data Paul, I finally dug up my Multi-meter to test brake temps but your method makes the point well enough. Can you clarify your data a little though? You have 5 data sets, I am hazy on a couple things tested.

1. Can I assume you are testing a Noctua NF-A40x10 FLX 12V?

2. E3D Fan, is it the stock 30x10 fan?

3. When you say Stator Vanes, can I assume you mounted this to the Noctua 40x10?

4. Can you give rough estimate of ambient temperature in °C?

5. When cooling air only, do you have strong underwear to hold your brass balls?

If you can answer #4, I'll try to match your ambient with AC or room heater and run same test on my NF-A40x20 FLX 12V unless you already have one on order. Unfortunately I lost my stock heatsink fan so can't do any apples-to-apples comparisons but I can see if pull-config will damage Noctua. Noctua support stated max operating temperature was 160° but they didn't specify if that was C or F.

Update: Noctua got back to me, max op is +70°C with nominal max lifespan at +40°C so that will be our range.

MK2S kit owner since 8/15/2017