Yet another under-extrusion issue ?

Using MK3S+ with original Prusa PETG and default settings 230/240° for 0,4 mm nose and 0,2 mm layers.

First layer calibration provided good results.

Oozing a bit too much needing cleanup before starting job... despite improved startup custom GCODE.

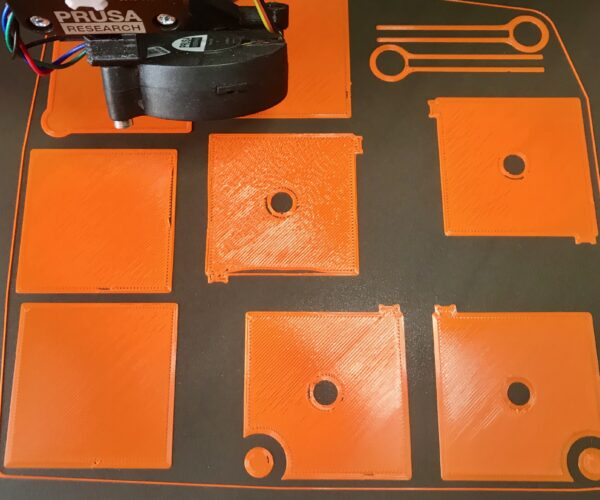

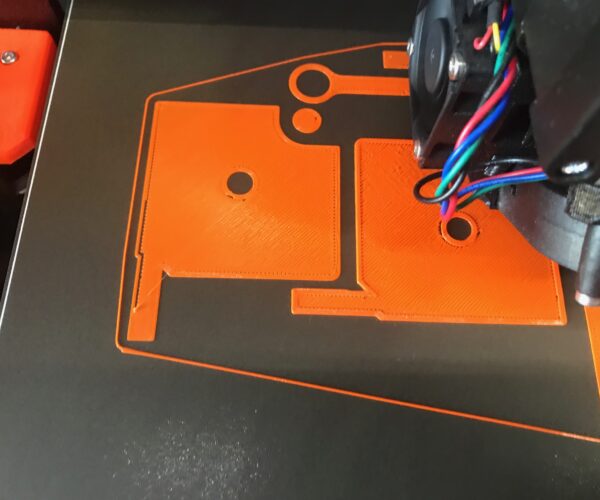

Anyway, now starting to build the Lack Table I am getting some issues with some parts of the first layer ...

All other layers are printed properly. What do I have to tune ? How ?

First layer : especially bad at the center of the bed.

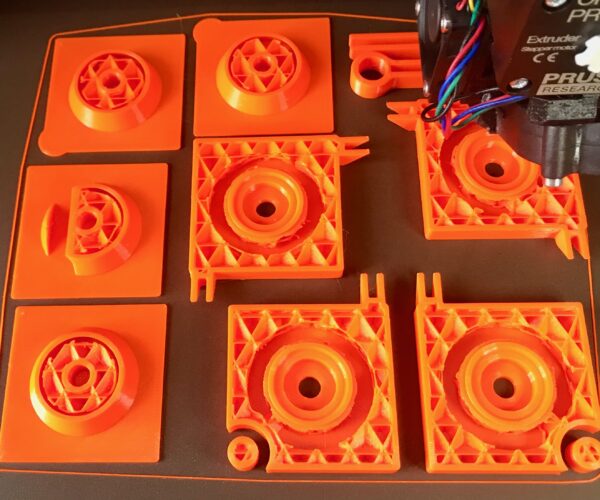

Next layers ok.

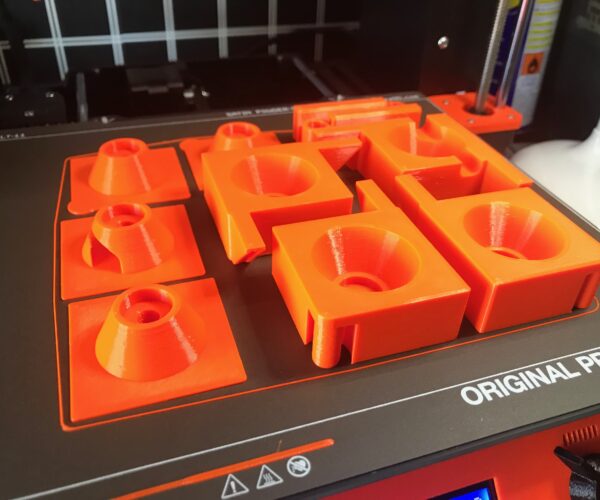

Job completed properly anyway !

Second set of pieces - same issue with only some parts on first layer ...

Next layers OK.

Thanks for your tips !

There are visible smears on your print sheet so a thorough clean may help.

Oozing and the imperfections in the print interiors suggest your filament is damp. Try drying it.

If the problems persist come back and we'll look deeper.

Cheerio,

RE: Yet another under-extrusion issue ?

Also, I'd try to get Live z properly calibrated for the middle of the bed. And after printing a handful of LACK enclosures I would also advise printing fewer parts per sheet and not filling the whole sheet. If something goes wrong you'll lose less, and it's not taking take much longer.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Yet another under-extrusion issue ?

Thanks for your tips, here are more info.

- I am using this print sheet for the first time and I cleaned it anyway with plenty of IPA. OK, I'll clean it even more.

- I am also using PETG for the first time. This one is Prusa PETG I got with my printer last year. It was stored since months into a dry box. The room is currently at 40% and 28°. OK, I'll try to find how to dry it more and probably tp keep it dry while printing.

- Strange that the problem only occurs on the first layer and only for some parts, not everywhere on the print sheet.

RE: Yet another under-extrusion issue ?

Now trying to find out how to adjust the Z calibration. I download a cube that could probably help.

RE: Yet another under-extrusion issue ?

Forget about the IPA. Well, not forget about it but first thoroughly scrub the sheet with plenty of hot water and fragrant-free dish washing soap. Then use 90+% IPA between prints until you see degradation of adhesion, then go back to the sink.

Of course it only occurs on the first layer, it's an adhesion issue. It's certainly possible your print bed is a bit skewed.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

For Z calibration:

To properly adjust my first layer (Live Z calibration), I use the built-in first layer calibration wizard in steps of -0.100 until I get a good zig zag pattern with the corners sticking and a reasonably looking square. I then switch to this calibration strip https://www.printables.com/model/105404 for fine-tuning in steps of -0.020 or even -0.010. The larger format makes it easier to read the results, compared to the in-built wizard, plus you can try up to 8 different Live Z settings in one print. It's a variation of this method https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/.

To quote @bobstro:

In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you’ve got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

A good Live Z should be somewhere around -1.00. But absolute values mean nothing, they depend on printer and sheet. A Live Z in the -1 range simply gives you enough wiggle room up and down, to adjust for different sheets and filaments. If you get close to -2.0 I would reposition the PINDA higher. This gadget may help you get into the proper range: https://www.printables.com/model/57192.

Textured and satin sheets are thinner than smooth sheets and require lower (more negative) Live Z. Even within one type (e.g. smooth) two sheets may differ in enough in thickness due to manufacturing tolerances to warrant different Live Z.

Also, any change to the hotend may require readjusting Live Z (including something as simple as a nozzle change).

A good description of how the PINDA works and how it relates to Live Z can be found at https://www.reddit.com/r/prusa3d/comments/9kab1l/can_someone_explain_the_concept_of_the_pinda_to_me/.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Yet another under-extrusion issue ?

Forgot to include the link for bed level correction: https://help.prusa3d.com/article/bed-level-correction_2267

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Yet another under-extrusion issue ?

Thank you very much for your guidance and your time !

Forgot to tell you that I never had any such issue while using the standard steel sheet and PLA.

I used the built in first layer calibration wizard when I first started using that sheet with PLA and could get perfect results.

This week, I applied the same calibration procedure with the satin sheet and PETG and could also get perfect results after some trials.

Before the Lack, I printed a router jig (100 x 100 mm) just in the middle of the sheet with no problem at all, perfect results.

Now I'll try a more complete calibration as you suggested because I also need to get more precision when I print tools for my woodworking jobs.

The printed dimensions never match my drawings. Also busy working on this topic...

The printed dimensions never match my drawings.

You are laying hot filament on to a heated plate - then it cools and contracts. For high precision it is normal to have to calibrate in prototype.

Cheerio,

RE: Yet another under-extrusion issue ?

Totally agree re cleaning the sheet, drying the filament, and dialing in your Z calibration.

You may also be printing a little hot and possibly a bit too fast for your first layer in PETG.

I find printing another (non-Prusament) brand of PETG prints better at 235/85 first layer and 225/90 for remaining layers. I’ll also print the first layer at a speed reduced to somewhere between 50%-65% of default first layer speed on certain prints if they’re being finicky. YMMV but worth trying on a smaller print to see if it helps.

Cheers