RE: White Overture PETG poor performance advice and alternatives?

I did and I will try. At this point I've used about half the roll, so I don't know if they'll take it on return. Considering how few usable prints I've got from it I won't feel guilty, though.

You might want to contact them if you still have the receipt.

Or if you ordered on Amazon, just return it. I've done that for a couple of bad spools.

@randym9

Thanks for the kind words, I print with many different brands of filament when it comes to PETG, I use Hatchbox, Overture, and several other brands, and I have opinions about them all. I'm not endorsing any particular brand, my intention was to suggest that perhaps the part was not tuned as well as it could be for the brand and color of filament being used. I've had great results with all of them. it's hard to tell if people are just being sarcastic here sometimes, but I genuinely give my time and money to trying to help the community, at least as far as this forum is concerned, since this is the only place I post, or make an effort to help.

If you were being genuine, I thank you.

@ktm1090

I printed the part as you posted it, in the form of your .3mf, and I printed it with my Overture settings and the results were very different. For all intent and purpose, I didn't even tune the file I just used my setting for Overture PETG, and the result was just fine. I think you either need to learn how to print with Overture White or, If it's not to your liking, just stick with Hatchbox white PETG , frankly I see nothing wrong with either. you simply have to learn more to make it work for you, as time goes on I'm sure this will happen, if you realize that all filaments are different and you will have to tune each profile as they come, as well I want to mention Whites can be very different, it is a recognized occurrence for many brands.

Normally I would post my profile and offer a .3mf with my settings, however I'm not going to this time, I think you should play with the filament, and take it beyond it's recommended limits and see if you can figure it out. if you cant make it work for you then just don't use it, but if you can get it to work for you then you will have a new understanding of what you can do in the future, (WHEN THIS HAPPENS AGAIN). I wish you luck, don't give up, this will pay off.

Good Luck

Swiss_Cheese

The Filament Whisperer

@ktm1090

As I made my latest post, I saw yours, that prompted this post, for you, and anyone reading this.

I literally have hundreds of rolls of filament here at my home, not including the several hundred rolls I have at work, it is a learning experience, in all of those hundreds of rolls of filament, I have only ever had one truly bad roll of filament, and this is ironic based on the information you have given in this thread, but the one truly bad roll of filament I've ever been subject to was a roll of Hatchbox white PLA. For the record I had several good rolls of the same filament before that to compare it to. My POINT BEING, poor quality rolls happen, however more often then not, it's folks giving up on, or not having the experience to, figure out the filament and develop a profile for it.

I'm going to suggest to you that you not give up, since you still have some overture that you paid for, I believe you will benefit from this.

Good Luck, again

Swiss_Cheese

The Filament Whisperer

RE: White Overture PETG poor performance advice and alternatives?

@swiss_cheese

No sarcasm intended on my part. I understand how comments on open forums can be interpreted in various ways and I in no way meant to sound disingenuous.

I am very new to 3D printing, having purchased my first and (to date) only machine, a MK3s+ this past July as a kit. I have a reasonably competent mechanical and electrical controls skill set and, coupled with a naturally curious mind, felt assembling the printer myself would give me a broader understanding of the technology, as well as better prepare me for future maintenance and service requirements. I’m glad I chose that path.

I read the online assembly manual, including every comment, twice while waiting to receive my printer. I took my time with the assembly and referenced the online manual and associated videos throughout. The end result was a success and the printer fired up and showed everything well in spec so I was quite pleased and eager to start printing to see how this all really works.

I didn’t discover this forum until sometime after completing the build when I literally couldn’t get anything to stick to the textured build plate. I was using the galaxy grey Prusa PLA that came with the printer and I was frustrated beyond words that I just couldn’t understand why nothing worked as expected. The built-in live adjust z routine just left a floppy string of filament on the bed and it was a miracle if the “flag” would sort of remain in one piece at the end of each trial run.

Bear in mind I had never seen a 3D printer, never mind witnessed one operate, until these first failed attempts. I didn’t know what I didn’t know, and I came to this forum seeking information and advice, which I discovered in mass quantities.

I spent a great deal of time reading about first prints, live adjust z, the different print surfaces, filament types, and on and on. The answers to most of my total noob questions already existed so I just tried to absorb as much information as I could to help me get started. I only have the (1) textured print plate which many people have struggled with, particularly when printing PLA. This filament was all I had because it came with the printer and I didn’t have any clue it could be a problem. So I bought a roll of PETG which many people said might stick better to the textured sheet, scrubbed my build plate in the sink with scalding water, Dawn dish detergent, and a scotch-brite sponge and voila, I began to have some measure of success.

I owe you a debt of gratitude for the incredible care and patience you extend to anyone who comes to this board seeking help. I’ve learned so much from reading about other people’s print issues and your responses to them that I can’t thank you enough. I look forward to seeing your posts in response to someone’s print problem because you’re so thoughtful and invest so much of yourself in helping others. That 17 hour print of the car door in another thread, more than once, blew me away! Who does that?

I’m frankly stunned that you, and others here, give so freely of your time, money in materials, and wealth of experience to help strangers on this site solve a printing problem. Honestly, I’ve never come across a community of enthusiasts so open, generous, and genuinely kind as the people on this board. No place not ever.

Anyway, when I replied earlier in this thread that I had printed a “fair amount” of Overture PETG, I was only trying to share what little experience I had with the OP. When I saw your post immediately following, with the photos of one billion rolls of filament, I realized how foolish I sounded. I have done so little and still have so much to learn and you have done so, so much.

So thank you again for all your contributions here. I will continue to follow you on this forum and strive to absorb as much knowledge as possible. One of these days I’ll have a question of my own and will look forward to the overwhelmingly positive responses from this community.

Thank you to all the good people here who make this such a great site.

R-

Thank you

@randym9

Honestly, I’ve never come across a community of enthusiasts so open, generous, and genuinely kind as the people on this board. No place not ever.

Me either, it's the reason I stayed.

when I replied earlier in this thread that I had printed a “fair amount” of Overture PETG, I was only trying to share what little experience I had with the OP. When I saw your post immediately following, with the photos of one billion rolls of filament, I realized how foolish I sounded. I have done so little and still have so much to learn and you have done so, so much.

This made me not feel good about how I presented that. (I'm not the politically correct type) That post was directed towards the OP who at the time did not seem to be paying attention to my suggestion that they post a .3mf project file, they probably thought I was crazy, and several other users were going straight for "Oh your filament must be bad".

I recognize how rare it is to have BAD filament, wet filament can cause these problems also, but it's not bad it just needs conditioning. In many cases (assuming dry filament) you just need to adjust your filament profile, in the same way that you might tune a model for printing, in fact that's part of tuning for printing, I'll stop here, that's off the subject of this post.

My intention was to get the OP's attention, since they probably thought of me as "Just some guy on the internet" which I am 😉, but I know things, and I wanted to see if the OP's settings were causing the problem, and they are. I admit that was a poor way to get there, and in all honesty I had almost made that post several hours before but talked myself out of it.

I thought that your post was well written, and with good intention, I don't agree with the filament being bad, however I understand why folks think this, and it was not my intention to diminish your experience. I would encourage you to continue to post and share your knowledge, it's the best way to grow and learn. If someone disagrees with the information your posting don't take it personally, just give it consideration and decide if you think that's correct or not, if it was me and I felt strongly in opposition, I would ask for some validation, Hence the .3mf a most wonderful tool.

Randy, Welcome to the forum 😊, please keep posting of your experiences, and please don't let person's such as myself discourage your enthusiasm, or desire to help, your experience is valuable.

This was eye opening for me.

Thank you

Swiss_Cheese

The Filament Whisperer

RE: White Overture PETG poor performance advice and alternatives?

I have to agree the community is great. On Overture, I just got two new rolls to test - PLA Pro.

--------------------

Chuck H

3D Printer Review Blog

No, thank you!

@swiss-cheese

Thank you for your kind words and warm welcome. You have nothing to not feel good about. I get why you responded as you did and I now know that it wasn’t directed at me (although you’d still be it the right had it been). I’m sure you can appreciate how I misunderstood your intention. But it’s all good, I have a thick skin anyway so I can be hard to dissuade!

Again, I’ve learned something, which is why I come here. I know now that my comment about a “bad roll” of filament was ignorance on my part and simply uninformed conjecture. Thank you for sharing your wealth of experience and pointing to the facts in this regard. I had no idea that a bad roll of filament was such a rare occurrence (you read about all the time 🙄).

Anyway, persons such as yourself could never discourage me from showing up. I’m here to learn. Keep doing what you do. Many thanks.

R-

RE: White Overture PETG poor performance advice and alternatives?

I'm still working with this filament. Optimization is the worst part of my real job and this is a hobby, so I'm not exactly excited or enjoying the process but I'm stubborn. I'm building a new printer on a bear frame with linear rails, etc. because I enjoy the mechanics and electronics and have some issues with my MK3S+, a lot of which aren't really addressed by the bear/linear designs out there. Also, it's just plain fun to tinker. I really wanted white printed parts with red accents, and since I'm designing and refining the vast majority of the parts I might as well take the time to figure out the color while I'm going through the prototyping process.

Currently I'm getting best results with 280 C first layer, 270 C after that, more cooling, 100 C bed, super tight extruder idler and upped the e-axis current to account for that. Not super happy about the last bit, the stepper is getting hot as hell, but it seems to maybe have helped with the inconsistent extrusion a little (jury's still out). None of that was necessary with any other color, but this filament is just hard to extrude. I'm still running really slow, which with the high temps was causing bad melting issues, hence the increased cooling. I took my hot end apart again for a thorough inspection and to make absolutely sure my thermal paste was good just in case there was some heat creep going on. I've also had to boost the retraction and decrease my extrusion multiplier because of stringing and burned up nozzle blobs at higher temps. So now I'm getting more consistent prints, but the dimensional accuracy is poop and they're brittle for PETG. At this rate I can get usable non-critical prints, but nothing requiring a precision fit. Also, any single-wall support material fails after a couple mm and bridging is horrible at the high temperatures, so I'm having to design in special, more robust supports. They're a pain to remove and would be unnecessary with a different color.

Anyway, I'm almost done with this roll and have ordered a roll of Hatchbox (back in stock) white PETG as well as Hatchbox transparent white. I'll see if I can get back to accurate, strong parts with those.

I'm pretty put off by your comment that you were able to print those parts just fine with your settings but you won't share them. That's not helpful to me or anyone else. When I mentor students I ask them to make an effort but I don't leave them to just flail, especially if they come to me with a list of what they've tried and examples of the issues they haven't been able to solve. I, and I'm sure anyone who reads this in the future, would really appreciate some advice, even if it's just "try higher temperatures", otherwise please don't reply That's why I've been descriptive with what I've tried so far and the problems I'm having. Additionally your comments about learning actually made me more inclined to return this roll and give up on this thread. I only stuck with it out of stubbornness after having a few successful prints with the red roll and normal PETG parameters.

@randym9

Thanks for the kind words, I print with many different brands of filament when it comes to PETG, I use Hatchbox, Overture, and several other brands, and I have opinions about them all. I'm not endorsing any particular brand, my intention was to suggest that perhaps the part was not tuned as well as it could be for the brand and color of filament being used. I've had great results with all of them. it's hard to tell if people are just being sarcastic here sometimes, but I genuinely give my time and money to trying to help the community, at least as far as this forum is concerned, since this is the only place I post, or make an effort to help.

If you were being genuine, I thank you.

@ktm1090

I printed the part as you posted it, in the form of your .3mf, and I printed it with my Overture settings and the results were very different. For all intent and purpose, I didn't even tune the file I just used my setting for Overture PETG, and the result was just fine. I think you either need to learn how to print with Overture White or, If it's not to your liking, just stick with Hatchbox white PETG , frankly I see nothing wrong with either. you simply have to learn more to make it work for you, as time goes on I'm sure this will happen, if you realize that all filaments are different and you will have to tune each profile as they come, as well I want to mention Whites can be very different, it is a recognized occurrence for many brands.

Normally I would post my profile and offer a .3mf with my settings, however I'm not going to this time, I think you should play with the filament, and take it beyond it's recommended limits and see if you can figure it out. if you cant make it work for you then just don't use it, but if you can get it to work for you then you will have a new understanding of what you can do in the future, (WHEN THIS HAPPENS AGAIN). I wish you luck, don't give up, this will pay off.

Good Luck

Swiss_Cheese

@ktm1090

I'm pretty put off by your comment that you were able to print those parts just fine with your settings but you won't share them. That's not helpful to me or anyone else. When I mentor students I ask them to make an effort but I don't leave them to just flail, especially if they come to me with a list of what they've tried and examples of the issues they haven't been able to solve. I, and I'm sure anyone who reads this in the future, would really appreciate some advice, even if it's just "try higher temperatures", otherwise please don't reply That's why I've been descriptive with what I've tried so far and the problems I'm having. Additionally your comments about learning actually made me more inclined to return this roll and give up on this thread. I only stuck with it out of stubbornness after having a few successful prints with the red roll and normal PETG parameter

I wrote an entire, page in response to this post, but all I could think of as I wrote it was this person just wants me to give them the answers, and doesn't really want to try. I deleted that page.

That's two lesson's I've learned from this post. go ahead return your filament, I can't help that attitude. So from now on it's going to be "No Reply"

No point in replying to this I'm not going to see it.

The Filament Whisperer

RE: White Overture PETG poor performance advice and alternatives?

@ktm1090

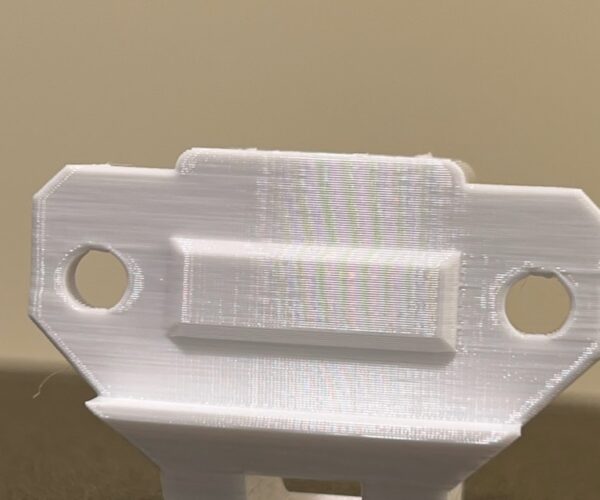

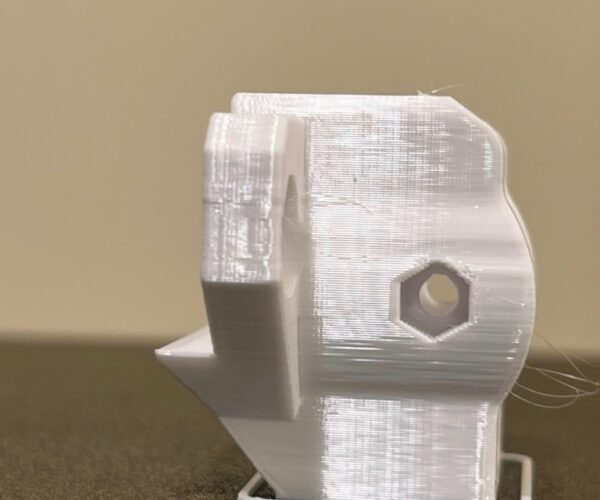

Since I have a roll of Overture White PETG, I downloaded your file to see if I could give it a go. Based on what you've already tried it's unlikely the settings I used will work for you, but I'll try to post pics and my zipped .3mf file just in case.

As I have previously stated, I have only the textured print surface so this may not be the best solution for you since you are having adhesion issues with that plate. As a point of information, and somewhat counter to conventional wisdom, I find that when I've been printing a lot of small parts for test fitting or prototyping, particularly small parts in the middle of the bed, and some obvious PETG residue is left behind, new prints actually stick better than to a spanking clean section of the bed (I typically do a quick wipe with 91% IPA and keep working to save time... I know, I'm lazy). When the prints cool, I have to flex the sheet to get them off the center of the dirty area of the bed. On a clean section, the prints self-release as they cool. I don't get it, but there you go. I mention this because you say you are having success with the red Overture PETG but not the white. Maybe try not cleaning the bed so thoroughly after printing the red and see if the white sticks any better? Just a thought.

Anyway, all I did was take your file, bring everything back to default values for Generic PETG, then make a few minor changes. I added a perimeter, and reduced the temperatures mostly. I sliced the file using the .02mm quality setting with 15% rectilinear infill and 4 perimeters. Personally, with the extra perimeter I think you could dial the infill back to 10% for this print as it's rather small and pretty dense.

I dialed the print speed back to 80% using the LCD menu on the printer after the first layer was down. I will do this sometimes when I'm unsure how a print will go and I want to reduce bed-shake & vibrations to give myself a decent opportunity of success. As I've already said, I'm new to this so I don't have a lot of experience working the magic in PrusaSlicer. But I am learning.

Anyway, I hope you get this sorted out. I know how frustrating It can be when you're trying to get something done and nothing seems to want to cooperate. I'll see if I can add my files below. Pics are all as printed, no clean-up. One pic is of the residue on the print plate; not sure how well that will show up. Best of luck. Let us know how you get on. R-

RE: White Overture PETG poor performance advice and alternatives?

@RandyM9 Thank you for doing all that, it's very helpful and I appreciate it a lot.

As to your point about the residue on the sheet, FWIW that's similar to my experiences with other filament and I wish I'd thought to try the red/white sequence (or one of my other PETG rolls). I also usually just clean up anything solid then give it a good wipe with IPA. Seems to have worked fine for multiple reuses as long as I don't get finger oil on the sheet. With this filament the residue is different, more like oil than plastic. Also, I have tried my textured sheet and couldn't get any adhesion, although my sheet is Ultistik and has been troublesome even with my usual PETG. I only got the satin sheet a few weeks ago and it's become my go-to favorite. For all of them my favorite treatment for getting the best surface finish is to clean with Dawn then put a single long swipe of glue stick on. Then I take a wet paper towel and sort of polish the glue onto the surface, like spit shining a pair of boots, until it seems like it's totally gone. That lets the surface of the sheet come through but the first layer goes down really well and parts pop right off, although it hasn't worked with this roll.

In looking at your pictures I'm totally convinced I got a weird roll. I have never had a glossy surface like that at any temperature. On yours I can see some ringing and VFA clearly, on mine they're really hard to make out because I get a satin/matte finish on the sides. With the red roll I get the usual PETG gloss. I really needed a couple parts yesterday so I printed them in red, they came out great. This morning after reading your post I tried again with your .3mf and the white roll. I got the first layer down, but at that temperature the extruder started skipping part way through and I cancelled it when I could see some tattered and unfused extrudate about 15% of the way in.

That was the last of this roll, so although I didn't solve the mystery I don't have any more for experimentation. USPS just dropped off a roll of white eSun PETG from Amazon this morning, though...

RE: White Overture PETG poor performance advice and alternatives?

@ktm1090

No worries, happy to help (or try anyway).

I agree my print wasn’t stellar with some obvious ringing and vfa’s. It was more about seeing if I could successfully print your part with the problem filament and less about fine tuning for me. That part has a lot of complex curves in the z axis, which I always find challenging. But my skill set is limited at this point so there’s that. Not making excuses. Fwiw, it does sound like there was something off with the roll you got.

I generally print PETG a bit hotter than the file I posted, but I’ve never tried to go up to 260. I know that hotter temps generally means stronger prints, but typically at the expense of fine details and more stringing; at least in my experience. I try to stay at 240 or below with layer height a significant determining factor. Generally speaking, I have to drop my temps down as low as 230 or even 225 to print at .15 mm layer heights or I end up with a melted mess about a dozen layers in on a small part like yours. I haven’t even tried a print at less than .15 mm...

Thanks for sharing the tip about prepping your build plate with the glue stick and wet paper towel to buff it into the surface. That makes a lot of sense and I will definitely give that a try the next time I print with PLA.

Also, I appreciate the feedback re the satin finish build plate. It looks interesting but I haven’t heard from many people who are using it at this point so your experience is valuable to me. When I ordered my printer in June of this year, I only bought the textured plate as Prusa was touting it as the only surface you need and I wanted to keep the cost below the US customs duty threshold.

Little did I know at the time that many people were having adhesion problems with the textured surface. Personally, I think Prusa is doing themselves a disservice selling the textured sheet and including a roll of PLA to new users without a BIG disclaimer. Even very experienced, highly competent people struggle with that print surface and there is a steady stream of questions and complaints to Prusa on this topic.

But after reading your post, I may order a satin sheet and some Prusament filaments to make the shipping worthwhile. I’m interested to see if the Prusament is obviously superior to the third party filaments I’ve tried so far. Most of what I read is positive.

Anyway, thank you for sharing your knowledge and experience. I’ve learned a lot through this exchange. I appreciate the opportunity to expand my own knowledge base.

I hope you have better luck with the eSun!

R-