What is happening here with Ninjaflex? Underextrusion?

I've attached a couple photos of the results of trying to print with Ninjaflex on my Mk3s (3.8.1), sliced in PrusaSlicer using the "SemiFlex or Flexfill 98A" profile. I'm having a lot of trouble and am trying to eliminate certain factors so if anyone could please help me with the questions I've asked (set in italics and centered to keep things organized) that would be greatly helpful.

Can anyone help pinpoint what is happening in my prints according to the photos (mainly why the gaps between each pass)?

I'm still learning so am by far an expert, but to me it looks like underextrusion, if not a combination of under extrusion and other problems. It's like there isn't enough filament coming out of the nozzle resulting in gaps between each pass. I had a few issues even printing this much. Based on my readings I changed a few settings from the default Flexfill setting in PrusaSlicer. They included:

Print Speeds - I changed all the various print speed parameters to 15mm/s for safety. However, the printer definitely ignored these settings and when I started printing it was zipping around extremely fast. I had to physically go into the Menu>Tune>Print Speed on the i3 and turn it down to 15 to in order to allow enough filament to come out and stick to the plate.

Why is the printer ignoring the settings I set in PrusaSlicer?

Retraction - I changed the various "retraction" settings to "0". Not sure if the printer followed these directions or not but I changed them.

As I stated, it seemed like the printer was ignoring my settings from Prusa, so while it was printing I went into the Menu>Tune and had to change both the "Flow" and "Speed" setting pretty dramatically to even make it this far. I turned "Speed" down to 15 (from 100) and "Flow" all the way up to around 300 (from default of 94 I believe) which still didn't seem to be enough. I know this setting corresponds to the "extrusion multiplier" in Prusaslicer, which was set to 1.15 or something like that.

Why does my printer seem to be severely under extruding the Ninjatek?

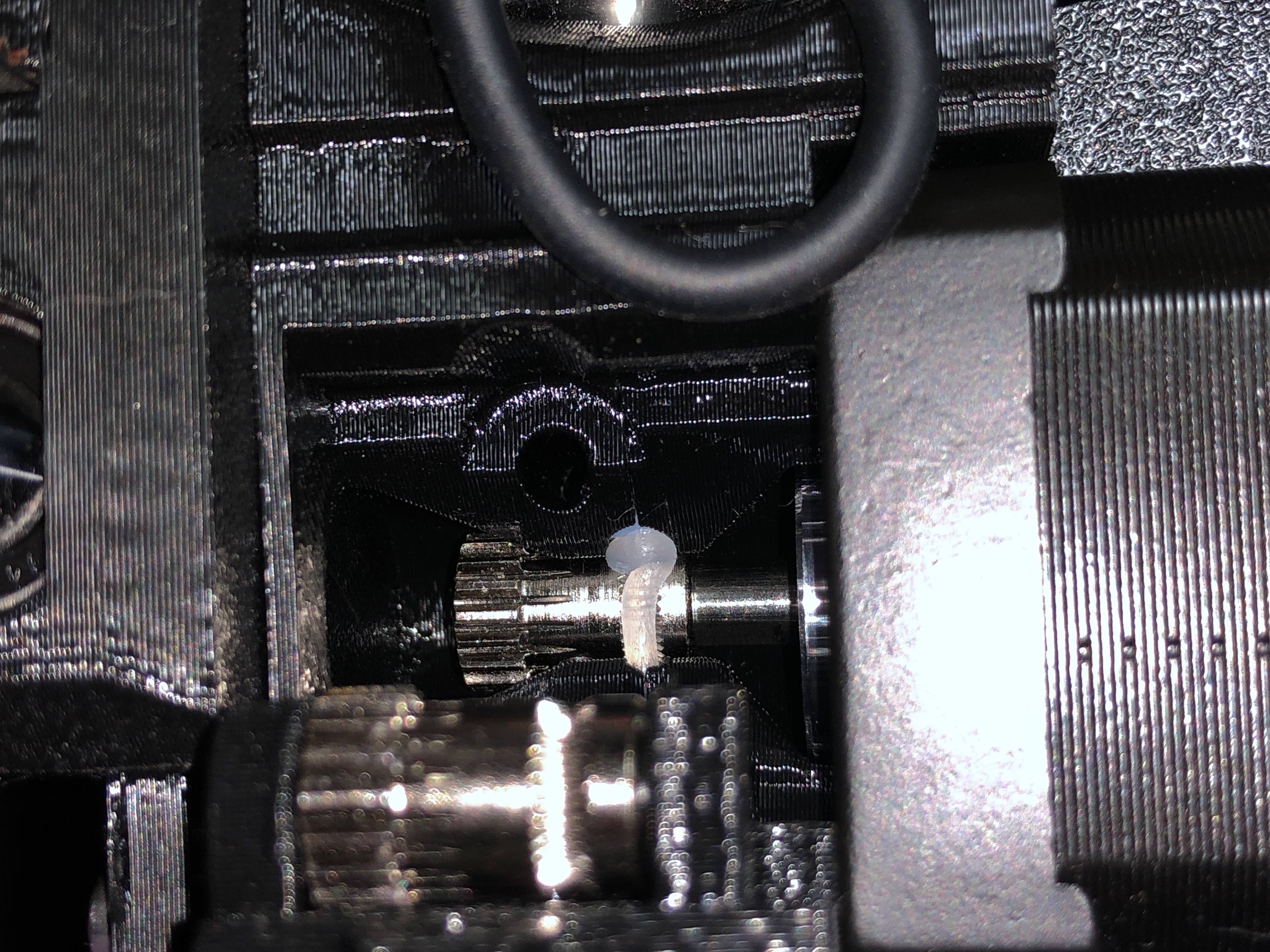

Finally, this was my 3rd or 4th attempt at this. Each previous attempt failed due to the filament wrapping around the bond tech gear and started coming out the side. I finally loosened the idler screw all the way and tightened it one rotation which seemed to take care of that problem. However, this time it seems like the filament got stuck inside the actual heating block or nozzle (past the bond tech). It made no noise at all and I didn't realize it was stuck until after a few hours of the print head moving but no progress being made on the print. I opened up the idler door and took the first photo.

Any idea how/why the filament got stuck like this and how to avoid this next time? Could it be temperature settings?

I had it set to 240º but bumped it up to 245º part of the way through. Thanks for the help.