What could be causing this ugly first layer?

Hey,

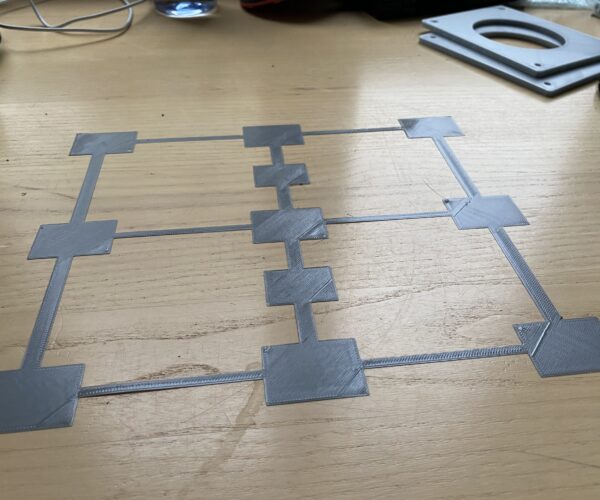

Please see the pic below. Two prints with the same printer, same nozzle, same spool of filament, same print bed, no changes in printer settings between prints. The sample above looks OK, the sample below has some ugly curls on the first layer lines.

Printer: MK3,

Fillament: PETG,

Temperatures and other settings default to DevilDesign preset that comes with prusa slicer.

What I tried to do:

- change fillament (also PETG, different manufacturer): doesn't help

- change nozzle (new, same size 0.4): doesn't help

- calibrate first layer: helps a bit! Lifting the nozzle prints a thinner line which doesn't curl so much. Still curls a bit, or if I lift the nozzle too high, then some lines are no longer filled with filament.

- change steel sheet: doesn't help (the problem would probably not be visible with powder coated sheet, but I prefer the smooth one)

Any ideas very much appreciated.

Karolis

no changes in printer settings between prints.

The second print shows typical ripples from a too low (too much squish) first layer Z calibration.

If you changed your nozzle the new one would have less wear and therefore need a fractionally higher setting to maintain the distance, redo the first layer calibration.

In due course, a few months, the nozzle will wear and need adjusting lower...

Cheerio,

Agreed. Typical signs of live z too low.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Got it!

I didn't realize bed level had to be recalibrated, as I replaced the old steel sheet with a new one, which was supposed to be identical. Except that the old one had been sanded a few times 🙂 Then after a few prints, I noticed the first layer issues and replaced the nozzle, which didn't help. Then I decided to go back to the old sheet, but the prints were ugly with the old sheet as well due to the new nozzle being slightly taller.

thanks

I'm still not quite sure the curly first layer lines are caused only by nozzle being too low. I downloaded the bed level calibration test file and printed it. First, when Z is way too low, normally there is a lot of excess filament building up on the other side, which I don't see in the test print. Second, see the closeup image of the top right square: On one side the nozzle is clearly too high because the lines are not filled entirely (I can see through the print). On the other hand, about 1 cm away the lines are already curling up, supposedly because of nozzle being too low. Something doesn't add up.

Try higher

This looks like it is still too low. With a good offset you will still see lines looking down at the print. You can determine that the offset is too high if the lines of extrusion are so far apart that you can see the sheet through the gaps. The gaps go all the way through the print. You take the print off the sheet and you can easily pull it apart. That is too high. With a good offset, it will be smooth when looking at the bottom of the print where it was squished against the sheet. See https://help.prusa3d.com/en/article/first-layer-issues_1804 for pictures.

Mk3S+,SL1S

This looks like it is still too low. With a good offset you will still see lines looking down at the print. You can determine that the offset is too high if the lines of extrusion are so far apart that you can see the sheet through the gaps. The gaps go all the way through the print. You take the print off the sheet and you can easily pull it apart. That is too high. With a good offset, it will be smooth when looking at the bottom of the print where it was squished against the sheet. See https://help.prusa3d.com/en/article/first-layer-issues_1804 for pictures.

In the area marked as LO in the picture, I can see through the gaps, and 1 cm away the lines are already curling up, that is the problem.

RE: re

Thanks for the clarification. Something other than z-offset, then. To rule out the obvious, have you checked for debris under the sheet?

Mk3S+,SL1S

re

I think the next thing to check is your filament path. Might you have a partial clog?

Mk3S+,SL1S

Maybe this

Do you think it could be loose trapezoidal nuts on z lead screws?

I had a similar problem with a CR10S once. All four screws had worked loose.

Do you think it could be loose trapezoidal nuts on z lead screws?

I had a similar problem with a CR10S once. All four screws had worked loose.

Could you be more specific about the screws I should check? I checked all the visible screws so far, all seem to be tight. The Z axis motors aren't moving, but there are probably some screws that are hidden and difficult to reach.

RE

this is a pic from the PKB of the screws I was talking about. But if you checked all visible screws. You should have already checked these also. HTHs