Weird ripple effect on first layer (MK3)

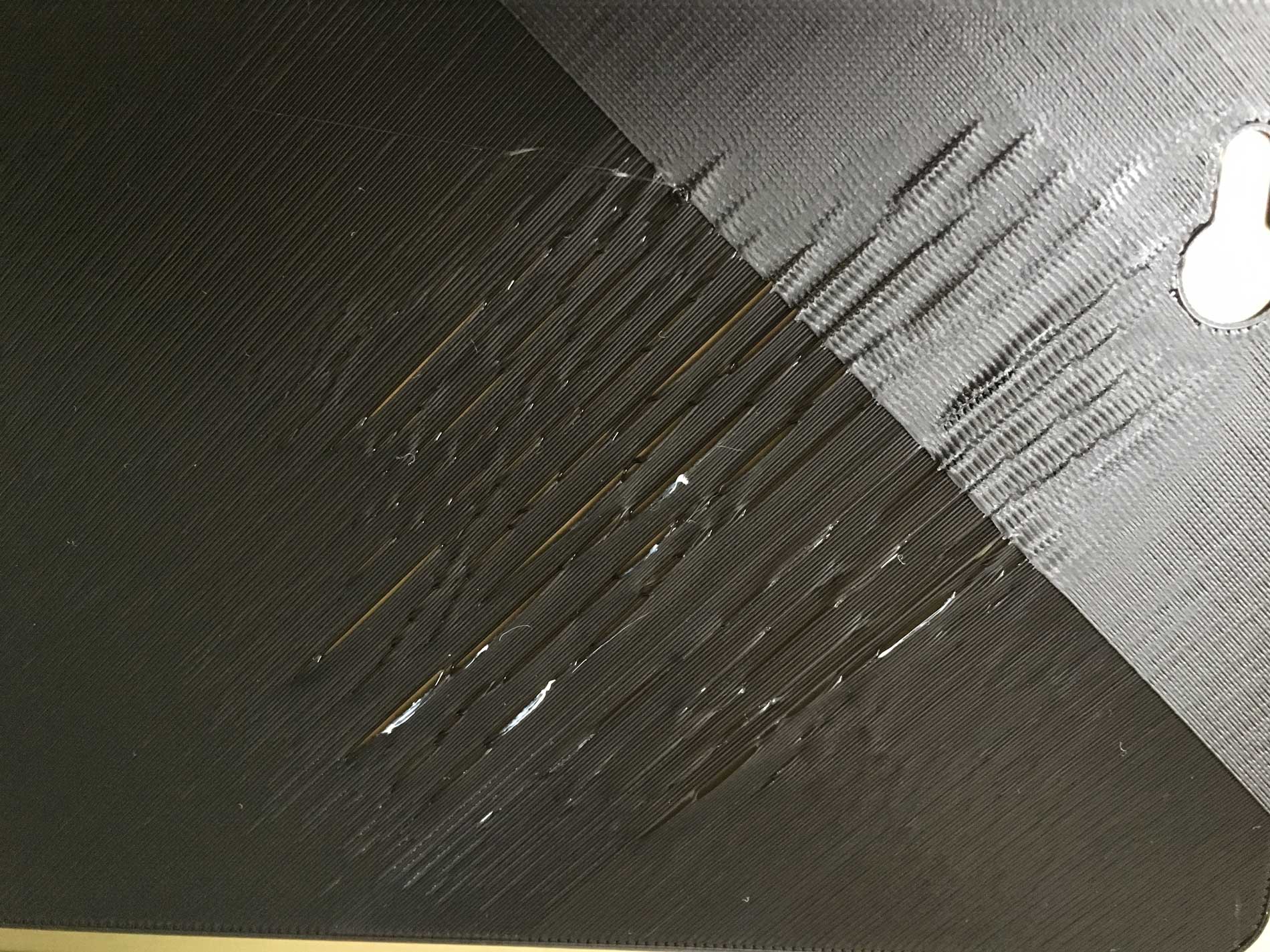

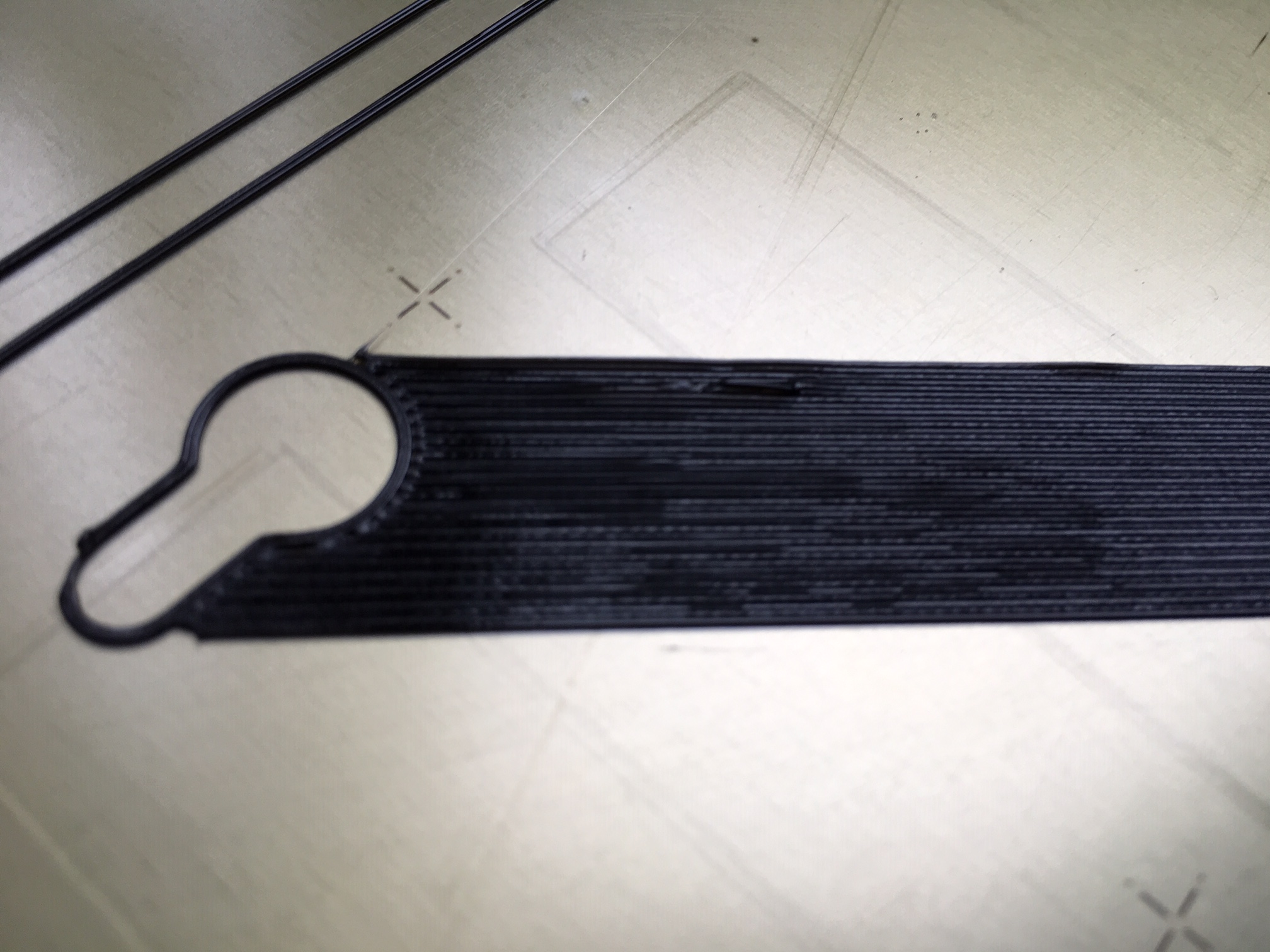

Hello, here is the bottom of my first layer (see attached images)

Printer: Original Prusa i3 MK3

Material: PLA (Ice Filament), 215° first layer, 210° for the rest of the print, note that this happens with all PLA I tested,

Slicer: Doesn't mater, happens with Slic3r, Cura, S3D...

Bed is cleaned with acetone, I then wait 5 minutes before starting the print.

I tried restarting the print, it happens on all prints, but at different places...

But I do not know how to call this kind of failure...

What do you think can be the cause of this?

Filament moisture?

Acetone residues?

Too high temp (altho sometimes it just works flawlessly...)

Something else..?

Thank you for you reading these lines

Best regards to everyone

Re: Weird ripple effect on first layer (MK3)

This looks like an inconsistent first layer height, and the first layer looks like the nozzle is a bit too high, at least in the area where you have the gaps between the extrusions.

Looking closely the indiviual filament strands look round, and don't seem to be welded together to form a uniform "foil".

First step is to get your first layer right, as describerd here:

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

If that does not eliminate the issue, you may have to check for print bed warping. But that's for later....

Re: Weird ripple effect on first layer (MK3)

This looks like an inconsistent first layer height, and the first layer looks like the nozzle is a bit too high, at least in the area where you have the gaps between the extrusions.

Looking closely the indiviual filament starnds look round, and don't seem to be welded together to form a uniform "foil".

First step is to get your first layer right, as describerd here:

https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html

If that does not eliminate the issue, you may have to check for print bed warping. But that's for later....

Thank you for your reply

Well, the printer has around 500hrs of printing, but the recent weather changes and temperature in the room might have screwed my Z-offset.

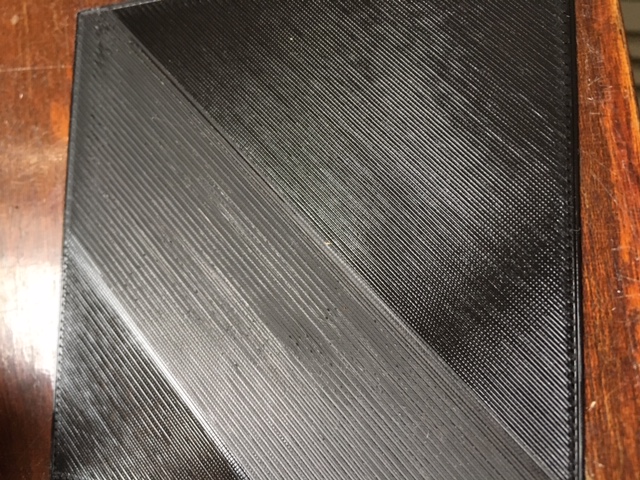

But just to be sure, I re-performed the Z calibration, Z-offset calibration, and used the GCODE provided in the url you supplied..

Top is my current Z-offset of 220, middle is a test at 370, bottom is another test at 270.

The Z offset of 220 seems to be the sweet spot..

After tuning the Z-offset, and tried another print, and ...

One part of the print is pretty fine, but the other part shows the same problem..

Re: Weird ripple effect on first layer (MK3)

The photos are a little hard to judge, but to me the layer height at -220 still looks too high.

Going from -220 to -370 is a MASSIVE change, that's 0,15mm, almost a complete layer height.

Making such a huge change even is a risk to ram your nozzle into the print bed. Make small adjustments, 20 microns then 10, even down to 5 to find the optimum.

I think you can safely try 260, 280, 300

I find the easiest method to find the right layer height is by pulling it off the bed and trying to pull the extrusion strands apart.

Yith your 220 setting I bet you can easily pull them apart, increase the Live-Z value until the layer is one uniform sheet of plastic, then you are at or very close to the optimum. (Assuming your extrusion is good, clean nozzle and right bondtech gear tension)

Re: Weird ripple effect on first layer (MK3)

The lack of adhesion suggests a cleanliness issue. I always use fresh paper towels cut into smaller pieces for wiping the bed clean. One or two passes per use. 91% or 99% alcohol. I've tried heating the bed and cold - can't say I've seen much difference except the warm bed dries much faster. 70% alcohol is okay, too, but you need to use more and let the bed dry longer since the 30% that isn't alcohol is usually water.

I've also found it helpful to wash and dry my hands before cleaning the bed since alcohol will wash the oils from fingers through the paper towel to the bed just as easily as washing oils off the bed to the towel. And I've learned to NEVER touch the bed surface with my fingers: only the edges. I use tools to remove parts. And if I do accidentally leave a finger print I clean it off immediately with alcohol.

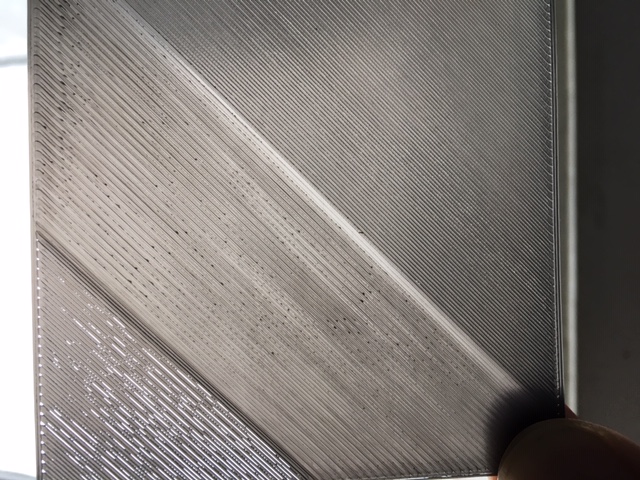

As for first layer, if the test patch has any strands that separate as you pull it off the bed the nozzle isn't low enough.

ps: This layer 1 test done with $15 cheap PLA - has all strands firmly welded together and are firmly welded to the perimeter. The layer is just under 0.200 mm, or 0.0075 inches. The area still attached to the bed doesn't look very good due to variable density pigment in the cheap PLA, but there are no gaps between strands.