Understanding Clogging - Carbon Fiber PLA

I'm having a really hard time trying to print with Proto Pasta Carbon Fiber PLA on my MK3S. I've tried a large range of temperatures, extruder multipliers, retraction settings, etc. but I haven't been able to complete a print successfully. My thinking is that I have some sort of clog but not sure... A little more detail:

Since the PLA requires a Hardened Nozzle I swapped out the Nozzle and put in a 0.4mm Hardened Steel Nozzle by E3D. Did a Z adjust/test with the CF PLA and was able to get a very good and consistent first layer at pretty much any temp between 215 to 245C and the usual 20mm/s speed that the default 0.2mm layer height settings have by default.

I then printed out a 40x40x40 cube in spiral mode to try to calibrate the extrusion which I started out at 120%. This worked (the first time) and I tweaked it down to 110% to make the walls closer to 0.45mm. Everything looked consistent. I raised the temp a little higher to 230 to get better adhesion between the layers.

Then I tried to print a benchy at 0.15mm layer height (Quality setting on Slic3r PE 1.4.3 which prints at about 45mm/s or less) with temp at 230C. It worked beautifully until it got to the roof and clogged. The extruder started to click and nothing was being extruded.

So I heated the nozzle to 250, and pushed the filament through until it started running smooth again.

Since then, everything went down hill. Whatever the settings I am not able to get the 40x40x40 cube to print. It'll get to about layer 10 (where it finished the bottom layers and has about 3-4 layers of wall) and then it'll start clicking and stop extruding. At first I thought it was my various test settings (tried incrementally going up to 245C, switching off retraction, going back to 120% extrusion) but I've reset everything to what it was when I printed the cube the first time and also get clogged there. A benchy will also stop printing around layer 10-15.

Thought it was nozzle debris and so since I had 2 hardened 0.4mm nozzles I tried swapping that out and put the unused one on. Same issue.

If I switch to a regular PLA, I can print just fine. I tried a simple test cube and that prints perfectly. I don't see any flaws indicating any sort of clog.

I'm wondering if there is some debris in the hot end before the plastic enters the nozzle? But then I'm not sure why regular PLA would print fine without any flaws.

At this point I'm not sure what else to try. I have this nice 500g roll of CF PLA (as a gift) but am about ready to throw it in the trash....

BTW, I did also try a 0.6mm nozzle and I also ran into similar issues, but since I don't have much experience with 0.6mm size and settings I've been concentrating more on the 0.4mm nozzle.

Anyone have any tips on clogs and CF PLA? Can there be situations where there is debris somewhere else other than in the nozzle, that could cause issues?

Thanks.

Re: Understanding Clogging - Carbon Fiber PLA

I decided to push the temperature to 250C and switch off the fan. I was then able to actually get a good cube completed! If I switch on the fan it clogs.

With a few more tries I push it to 260C with a 20% fan. I'm able to get a good cube there too and it looks good. I then tried the benchy at 260C but that didn't make it all the way before clogging....

So maybe I was just lucky the first few times and that's just what the material needs.

The temperatures are counter intuitive from what I've read. This is supposed to be PLA with temp range up to 225C... so I believe having temperatures that high has side effects? But maybe this is all because of the hardened nozzle not conducting heat as well... All my regular PLA printing usually falls well within the recommended range when using the default brass nozzle.

I'm thinking I'll try to push it to even higher temps to see what happens.

Re: Understanding Clogging - Carbon Fiber PLA

Just curious, have you tried to print it within range with the fan off?

Re: Understanding Clogging - Carbon Fiber PLA

I only tried 225C without Fan and that clogged too. I didn't try more temperatures around that though. I'm wondering if I should just not bother with the fan and have it off.... I was trying to find a temp where I could at least have it running somewhat as I assume I'll run into other issues once I can get more complex prints going.

Re: Understanding Clogging - Carbon Fiber PLA

I'm having a really hard time trying to print with Proto Pasta Carbon Fiber PLA [...] Since the PLA requires a Hardened Nozzle I swapped out the Nozzle and put in a 0.4mm Hardened Steel Nozzle by E3D.

Two things to keep in mind:

Try cranking back your MVS setting for that material. This will keep speeds at or below the maximum the hotend can process, but otherwise allow speeds up to your settings. This avoids having to slow everything down for tricky areas of the print and sets a safe upper limit at speeds. Check out results in preview mode after slicing to see the effect this has.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Understanding Clogging - Carbon Fiber PLA

1. For my MVS I've set this to 5 mm^3/s. I had started at 9 but then tried to lower it. Unfortunately it didn't seem to make a difference in the clogs. Is there such a thing as too low?

Also, I'm running on the 'Quality' settings on Slic3r PE which seem to be running speeds anywhere between 45 to 25mm/s. I was going to try to slow these down further to see if it makes a difference.

2. Yes, I've read that hardened nozzles require 5-20C more than recommended but here I'm running at about 40C over which doesn't seem right.

Re: Understanding Clogging - Carbon Fiber PLA

My guess would be heat creep. You're printing PLA which is supposed to print @220C max. With 250C and very slow print speed the whole extruder heats up alot.

Benchy roof is being printed usually <20mm/s which is always tough for HTPLA. I would suggest to bump up the print speed and maybe using 0.5 nozzle.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Understanding Clogging - Carbon Fiber PLA

At some point, things may simply be too slow, but you've ruled speed out it seems.

1. For my MVS I've set this to 5 mm^3/s. I had started at 9 but then tried to lower it. Unfortunately it didn't seem to make a difference in the clogs. Is there such a thing as too low?

Also, I'm running on the 'Quality' settings on Slic3r PE which seem to be running speeds anywhere between 45 to 25mm/s. I was going to try to slow these down further to see if it makes a difference.

You've ruled out the basics with slicer settings and speeds. I'd start looking for mechanical issues. Check the extruder idler, try manually feeding filament in from the top with the extruder screws loose and check for issues. Try cold pulls. Make sure the filament feed path is clear.

2. Yes, I've read that hardened nozzles require 5-20C more than recommended but here I'm running at about 40C over which doesn't seem right.

That does seem excessively high.

Hate to say it with an expensive reel of CF, but can you try another filled filament? Could it be wet? Try drying it out perhaps.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Understanding Clogging - Carbon Fiber PLA

MVS is set in two places ... make sure both are lowered to a reasonable value.

Re: Understanding Clogging - Carbon Fiber PLA

MVS is set in two places ... make sure both are lowered to a reasonable value.

Slic3rPE will use the lower of the two at slice time. I set it to 11.5 in my print jobs, then lower for specific filaments.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Understanding Clogging - Carbon Fiber PLA

I've found situations where one won't affect the print speed.

Re: Understanding Clogging - Carbon Fiber PLA

The comments on the MVS made me go research this a bit more. I also reached out to Proto Pasta to see if they had any tips. They have blog and setting information for their HTPLA CF filament but not their regular PLA one so I had thought these might not really apply to what I'm using (I assumed HTPLA and PLA are not really the same materials). However, the response from Proto Pasta said that their info mostly applied to this filament too except for the temps.

So one thing they say is that the Volumetric Speed should be between 1.5 and 9. I had set my max to 5 but there is no place to set a min. I realized that in my 40x40x40 spiral vase cube test the Volumetric Speed was being set to something < 1mm^3/s. I finally found that this was because of the min layer time of 20s. Setting this to 0 makes it so that the VS stays above >1.5 (and is basically determined by the Speed settings). Once I did this I was able to print a good cube at 215C with full fan going! So it seems like the filament must keep on flowing to avoid jamming.

I then moved on to the benchy and checked to make sure I stay above 1.5 mm^3/s in all areas. I still get a clog when it starts to get to the cabin areas above the hull so it's still not quite solved. I'm going to try to raise the temperature from 215 up to see if I can get it to finish. Considering the hardened nozzle and the comments from others, it would seem like my 'acceptable' range should be somewhere between 210 and 240.

Re: Understanding Clogging - Carbon Fiber PLA

Finally had some success. I think the following made the difference for me:

* Keeping Volumetric Speed between 1.5 and 9 by setting Speed and min layer times properly.

* Keeping the temperature of the environment down. I have an enclosure and it was getting to about 32C. If I keep it open it stays around 25C. I think I might have been running into a heat creep type of situation.

* Tweaking retraction. Initially I had tried no retraction but that didn't work. I then had gone with the 0.5mm retraction recommended by Proto Pasta. I scaled this back to 0.3mm and that seems to work great.

* Tightening the extruder idler. I've been struggling to find the right setting here. With the MK3S you only have 1 screw to tighten and the tension was fine for regular PLA, but I think with this filament there needs to be more pressure exerted to get the CF particles through the nozzle. It doesn't seem to be too tight where it'll deform the filament yet.

I was able to get a good benchy out and have gone down to 225C and it prints fine:

The layer lines are much less obvious in normal lighting. In general it looks great to me... no stringing, bridging looks good, etc.

Time to get some 'real' prints going now...

Re: Understanding Clogging - Carbon Fiber PLA

Thanks guys for the discussion and results, this should be made a sticky. I am going to try some CF PETG soon and the findings and comments and setting discussed here may well be vital to getting successful prints.

Thanks again.

KR

Andy

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Understanding Clogging - Carbon Fiber PLA

Hi all,

I'm coming into the conversation quite late, but this forum helped me and I wanted to share my successes on behalf of Proto-Pasta's co-founder, who thinks my successes will be helpful to others and reduce the pain on Proto-Pasta's support.

I struggled through the same clogging issues as andrea0-r6, and I used the info you guys found to work for the most part. After many late, frustrating nights, I finally got a 3Dbenchy to print at 215˚C with a painstakingly tweaked PrusaSlicer profile. After this success, I watched a video from the 3d Printing Nerd, where he had a clogging issue regarding Proto-Pasta's Matte Fiber HTPLA:

Alex, the co-founder of Proto-Pasta and the person I talked with over email, helped Joel with his issue and provided two solutions in the video:

a) oil the filament (which didn't appeal to me)

OR b) swap the Prusa heatbreak to an authentic E3D one

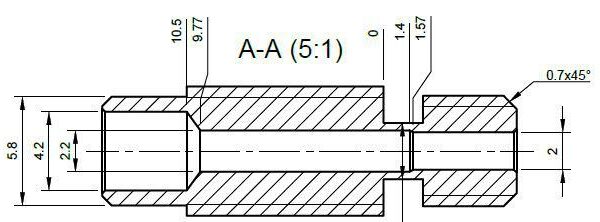

Apparently the Prusa E3D V6 Hotend comes with a Prusa-specific heatbreak, which has a taper point from 2.2mm to 2mm, which creates a ledge in the filament path:

Filament expands when it heats up, so when the filament retracts, it expands and gets caught on the ledge, causing a jam (or so I've been told). Prusa's heatbreak is supposed to help with multi-material filament changes, but for those who just print in one color, it provides issues like carbon fiber filament clogging. I changed out my stock heatbreak for a new titanium E3d one (spend the extra few dollars, it will eliminate heat creep) and I was able to get an amazing 3DBenchy at 0.2mm layer height with PrusaSlicer's default Prusament PLA profile, using a E3D Nozzle X.

So in conclusion, just spend 15 bucks on a new E3D heatbreak; if you know how to change a nozzle, you know how to change a heatbreak. The labor and frustration that comes from trying to tweak settings will ultimately surpass the heatbreak's $15 pricetag and 15 min of replacement time. Just make sure you grab some thermal paste along with your heatbreak 🙂