Ugly surfaces

Hi all:

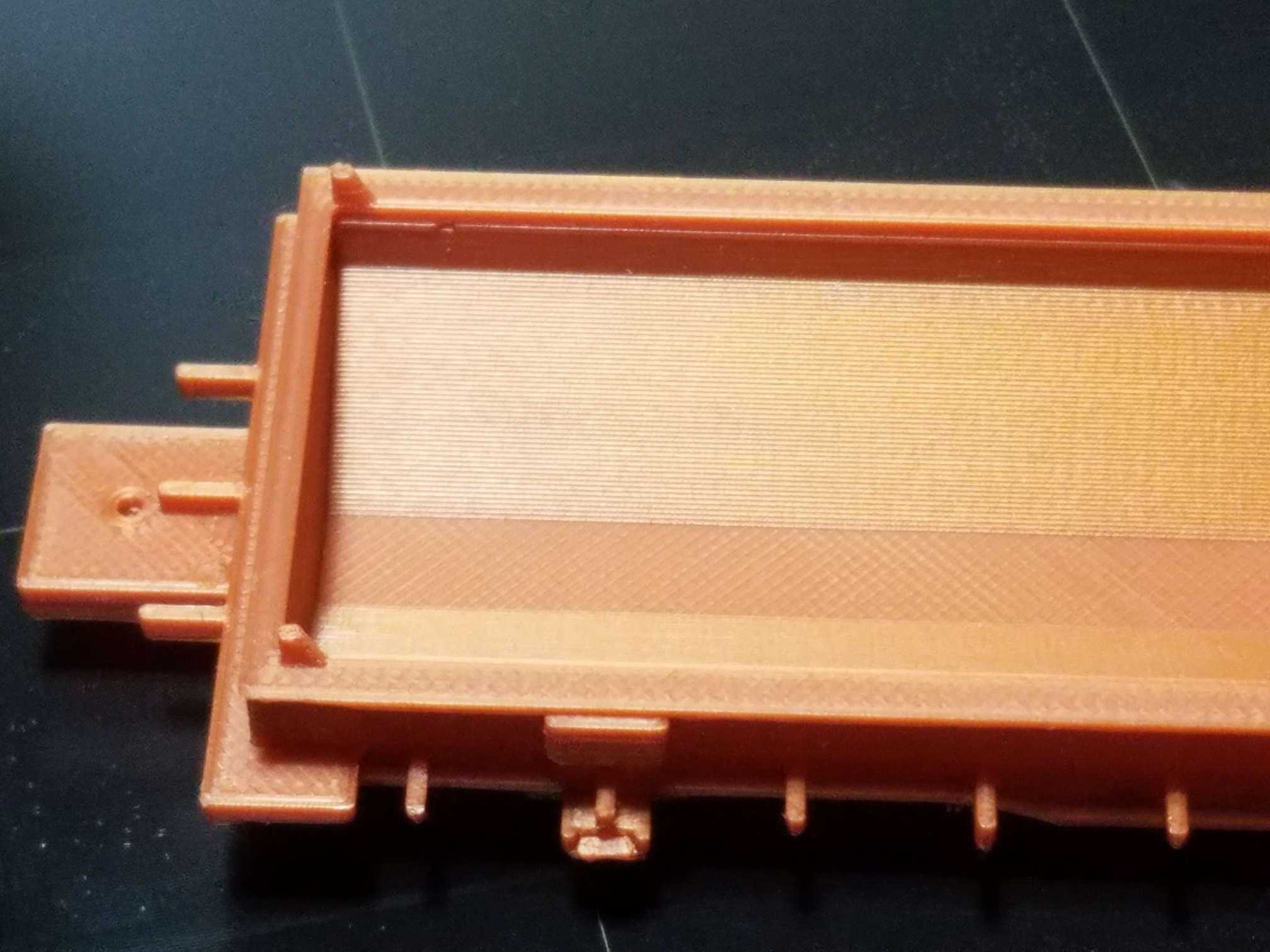

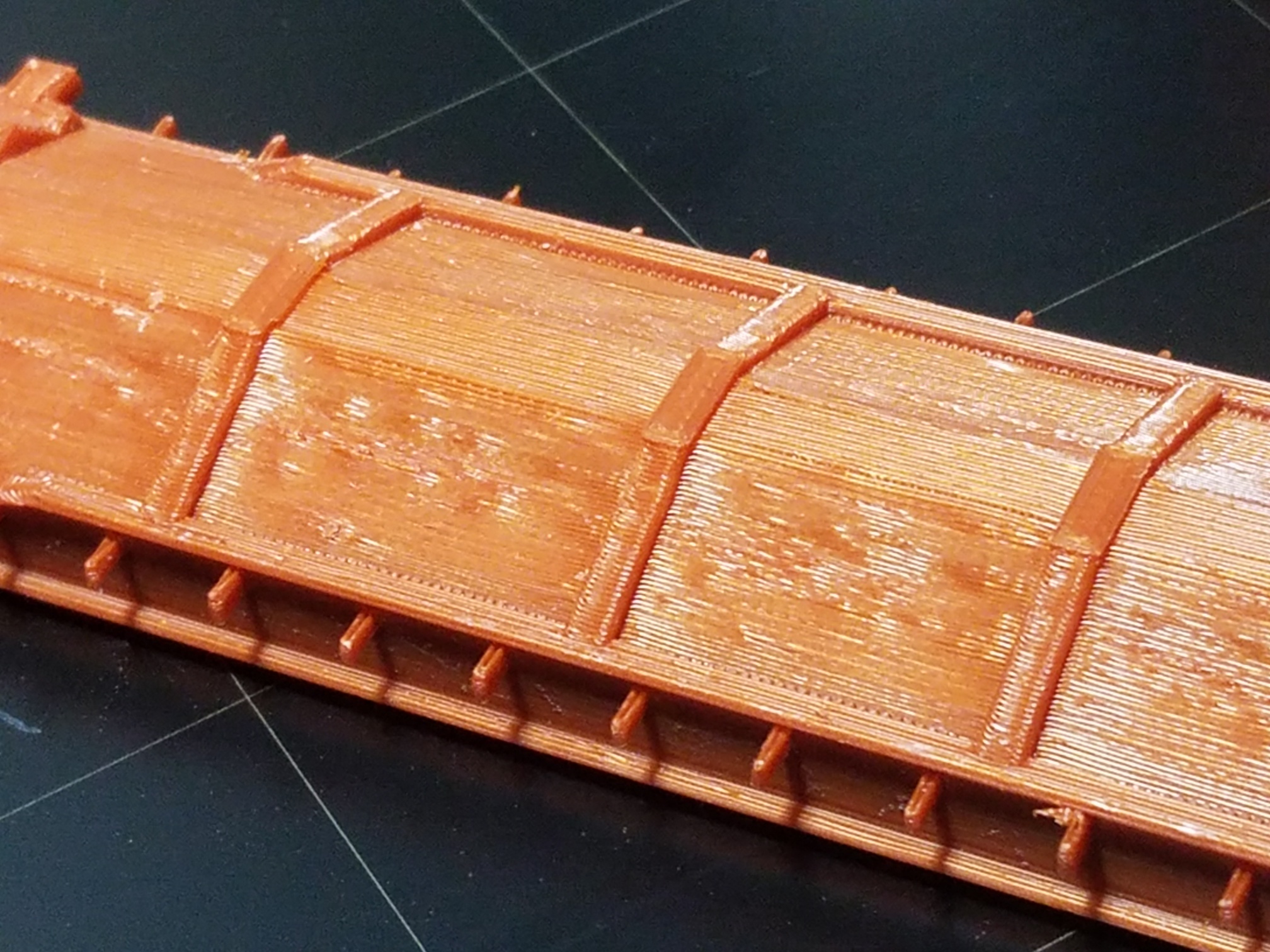

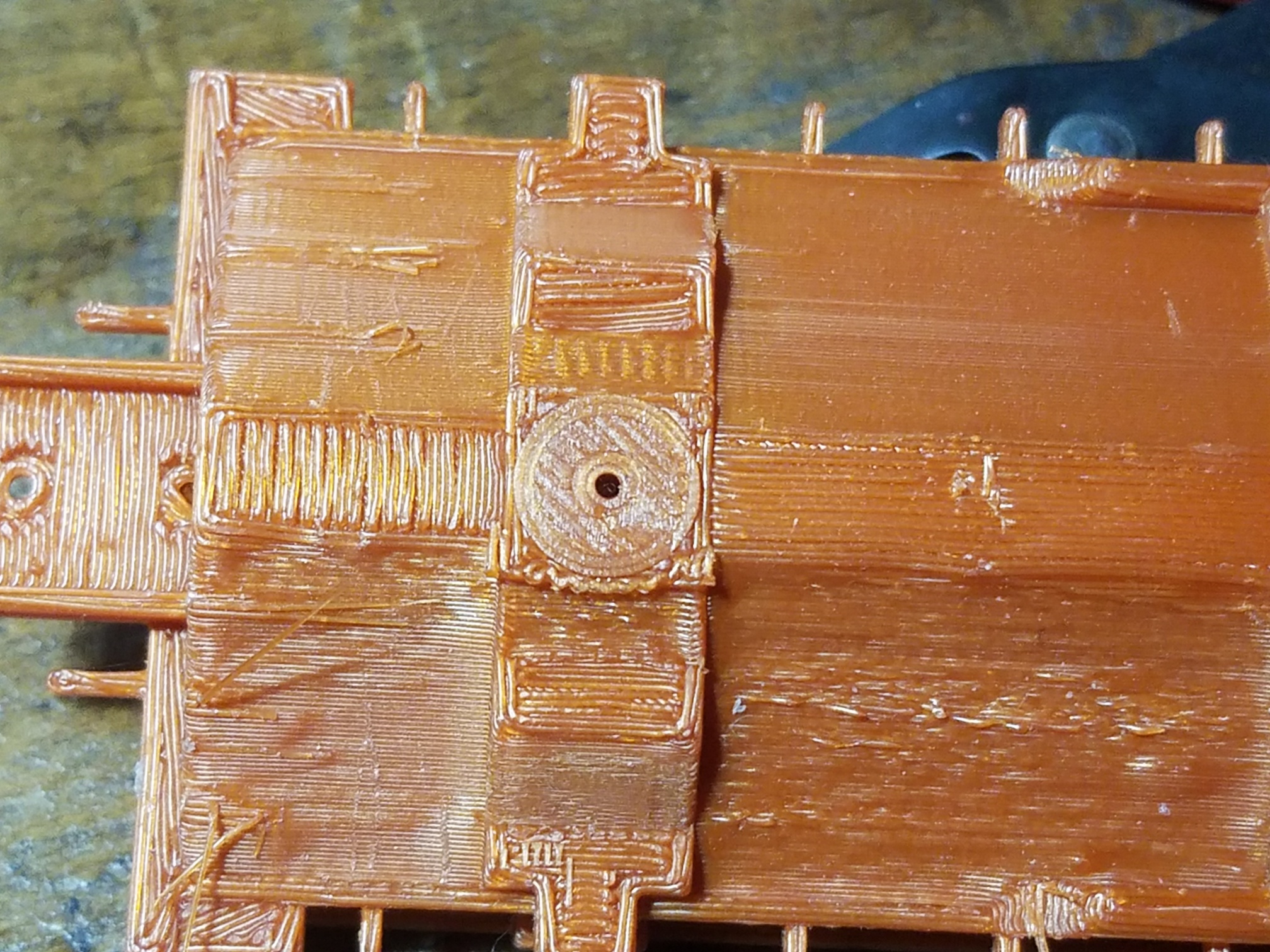

First post. I am stumped. I am using a new MK3, with copper Prusament, using standard PLA settings. I created a part in Solidworks, and then sliced it in SlicerPE. I am using standard settings in Slicr. First I tried no supports, and I got the bottom surface below. I then tried using rectilinear supports - same poor bottom surface result. I then tried hex supports, thinking that I was bridinging because I was parallel to the supports. Same poor surface. I am not sure what to do from here. The top surface is excellent (see photo below). I have absolutely no clue how to fix it. My son's printer printed a similar part, and it looked fine, with a nice surface. On this part, and the part my son printed with his MK3, I get the same poor surface.

Any ideas on things to try?

Thanks

Scott

Re: Ugly surfaces

thats actually pretty decent for supported layers.

if more bottom surface quality is required, then you need to find another orientation to print that part in that will not require supports, or modify it in a way to restrict overhangs to 45 degrees.

Re: Ugly surfaces

You can also try to decrease the support separation distance so that the filament has less time to droop before it solidifies.

Re: Ugly surfaces

I'm printing in the mk2s but my settings are for a good support face 0.2mm layer height. 0.85 bridge ratio and 0.06 support interface gap.

All I can say is give it a try. It works wonders for me.

Re: Ugly surfaces

I agree. That is not too bad for using supports. Support usually creates some roughness.

--------------------

Chuck H

3D Printer Review Blog

Re: Ugly surfaces

I don't see this mentioned but make sure your bridging/overhang fan cooling is at 100% as well.