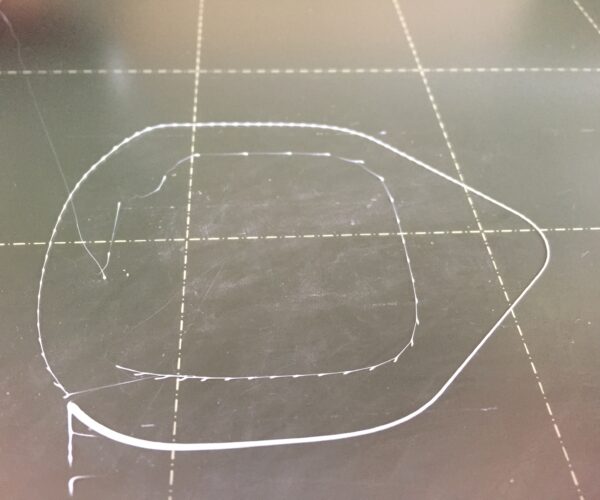

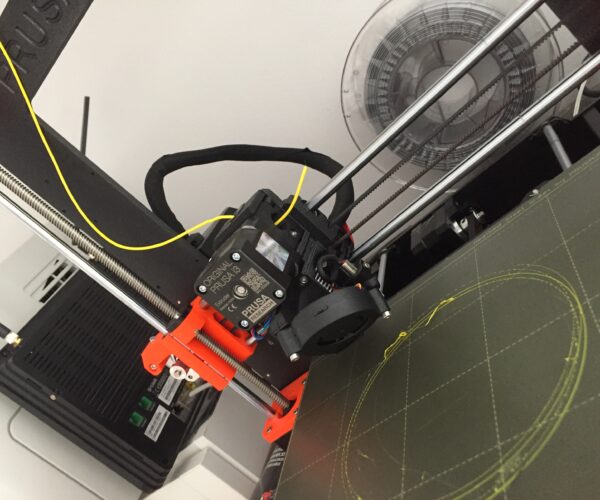

TPU - 1st layer calibration is working, 1st layer print fails

Specs:

-

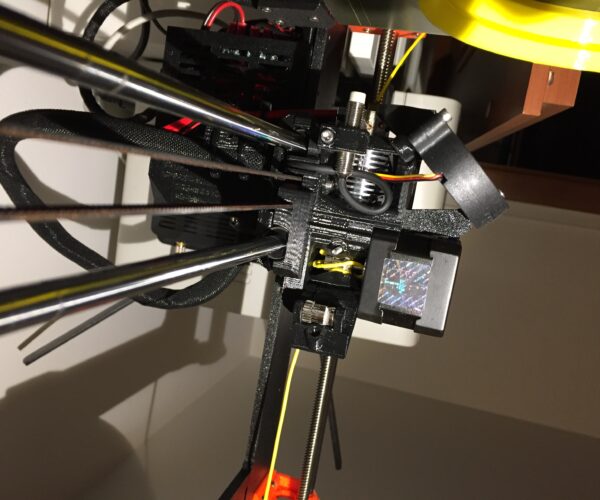

Printer - Prusa i3 MK3S

-

Hot end nozzle - stock 0.4mm

-

Filament - Fiberlogy FiberFlex 30D

-

Temperature - tried 210, 220, 230, 240 (manufacturer says 200-220)

-

Bed - 50

-

Slicer SW - PrusaSlicer

-

Retraction - off

-

Speed - all speed is set to max 15mm/s

-

Layer height - 0.2mm

-

First layer height - tried both 0.2mm and 0.25mm

-

Extrusion multiplier - tried 1.1, 1.15

-

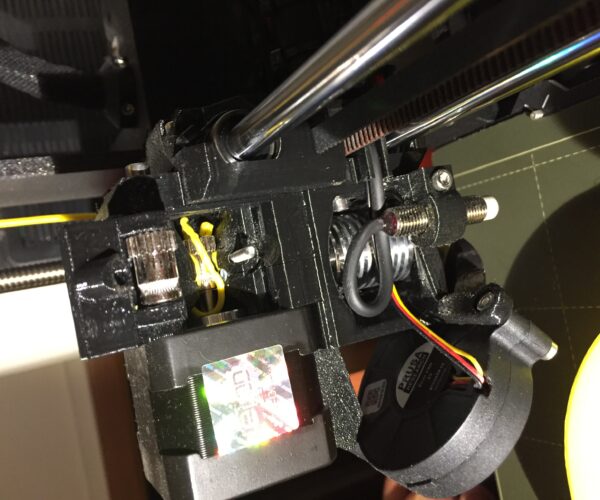

Tension screws - tried as loose as possible (when tiny movement would open the doors) and medium tension (the same that works with PLA)

RE: TPU - 1st layer calibration is working, 1st layer print fails

Hi I have the same problem.

I’ve tried many times with many different settings and after almost all the print was failed.

One try was successful when I turn off vase mode. But it wasn’t finished because of filament was jammed. I think it was done during rolling out the filament.

Next tries with the same settings where bad.

I used the same filament and the same printer model, and also settings.

Anyone can help?

RE: TPU - 1st layer calibration is working, 1st layer print fails

Hi I'm having the same issues.

I found some info on another post at this link: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/prusa-i3-flexfill-original-extruder/

Here is my reply to this post, it's not a great solution but it's the only way I could get printing.

"

Hi guys,

don't know if this thread is still going. This is my first post on the forum. I have a MK3s. First printer and new to it, so still learning the ropes.

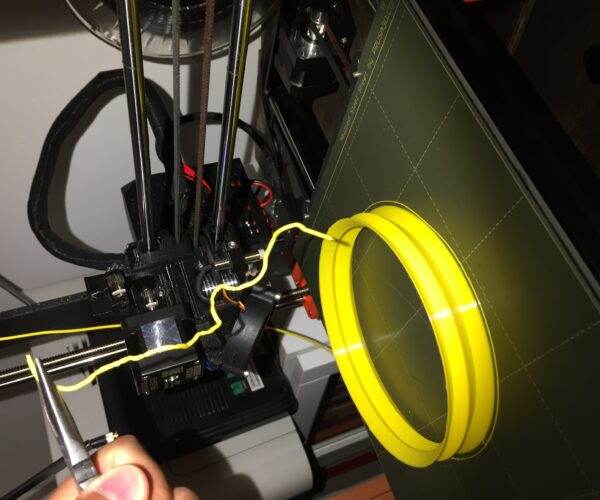

Anyway, thanks for the tips on printing with Fiberology Flexible filaments. I'm using the 30D. I've had a real hard time to print this filament, even with all the tweaks from this thread. Then I figured out that the prints were going wrong at a certain point. I'm not sure what the term is for the big squish of extruded filament that the MK3s squirts out immediately after the bed leveling routine and just before the extruder moves across to the print- maybe it's called priming the nozzle or something like that! So loading the filament is fine- material comes out, all good. After the bed leveling the thick squish is good too, then the extruder moves to the print and nothing, like the material has stopped flowing by the time it gets to the work area. I tried everything suggested including changing the nozzle height from the build plate. I had to keep stopping the print, unclog the extruder and try again, spent many hours doing this.

So between the nozzle priming and the print starting I stoped the print right after the priming, unloaded and reloaded the filament and then resuming the print, and this seems to work great!

So I don't understand what it is that happens between the priming the nozzle and the print starting, but my fix seems to help things get going properly.

If there is a better solution, some setting to change after the priming, I would greatly appreciate any help.

Cheers"

I hope someone can shed some light on whats happening to clog the extruder wHen it moves over to the print.

RE: TPU - 1st layer calibration is working, 1st layer print fails

@pari

Hi I think I almost found resolution.

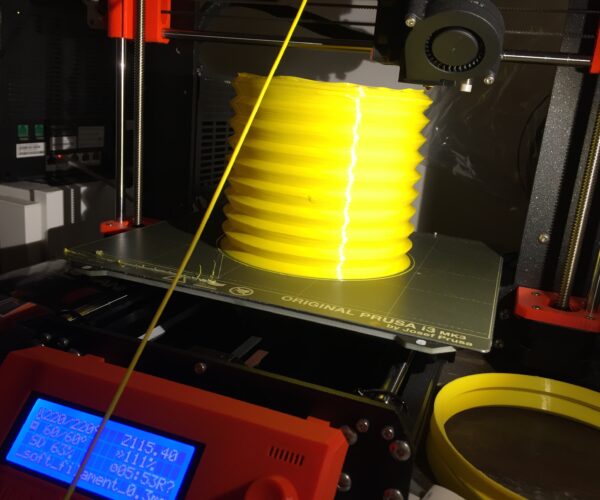

I think the key problem of jamming filament is The moment when it stretches too much when it’s try to roll filament out from roll.

When I put the roll on the floor horizontaly and even I set speed to 136% and set layer height to 0.3. The print was good and I think it will finish successfully. But this 19 hour print I had to pause . and then when I unpause printing there was a error :/ First few layers didn’t go well, and the rest goes bad.

I think also important is when you start printing with flex filament you have to increase the extrusion level to above 150 then when the print is stable you can decrease to 100%. And I think also when you increasing speed you have to also increase exclusion level

RE: TPU - 1st layer calibration is working, 1st layer print fails

Hello,

Here I am, over a year from the date of this topic with similar issue with the same material (Fiberflex 30D). Has any of you guys found a resolution? I'm using basically similar settings, based on Filaflex profile, speeds down to 20mm/s, no retraction. Loading the filament (via axis movement) works just fine, even if I back the E-axis 1-2mm (like a retraction move) and then proceed forward it extrudes fine. Also first layer calibration prints with no issues. Using technique provided by @pari I am able to proceed with my print (while ejecting there's a "jamming bend" visible on the filament), while cutting off the mangled piece and loading up the filament again. During the print itself printer seems not to have any issues with pulling the filament from the spool, so I don't think the tension between the spool and extruder is an issue.

This still remains a not very elegant workaround (although working), so I would be very thankful for any support.