Thin and large PLA plate printing problem

Hello!

I'm very new in the 3D printing world and I'm facing problem when I'm printing a thin (1.5mm) and large (90x45mm) PLA plate.

After few layers small portions of the plate lift up a bit and the plate start to move on the printing bed.

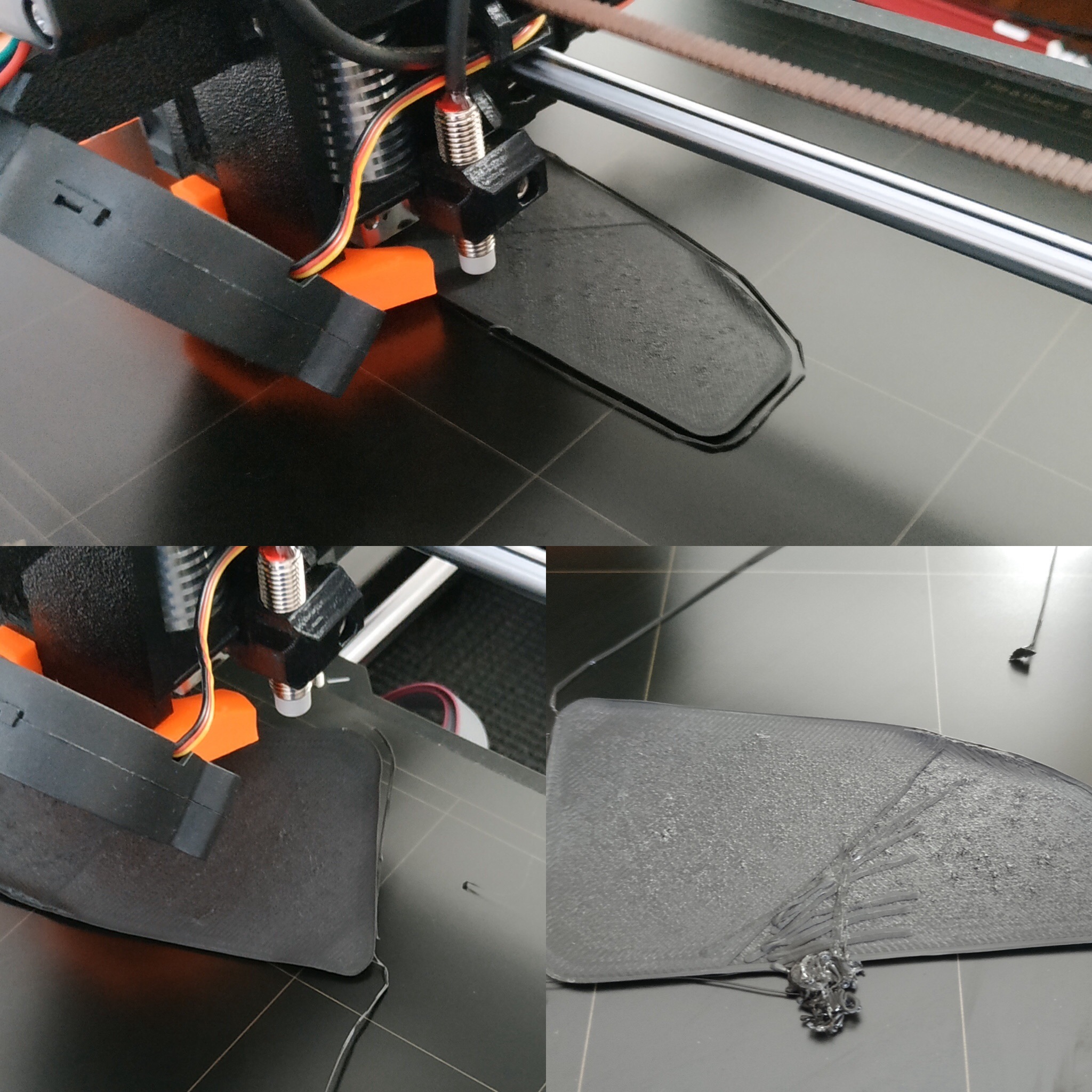

Here a picture of the moment when the plate goes off from the printing bed:

It seems to me that the adhesion between the PLA and the PEI bed is poor.

I try to use the brim but the PLA wire doesn't stick well to the printing bed so using the brim doesn't even let me start the first layer.

I use isopropholy alcohol and acetone to clean it as written in the manual.

I'm using the standard setting (Prusa control software) 215° / 60° (noozle and bed temperature).

Printing speed is 100mm/s. I've tried to reduce it at 90 and 80mm/s but no improvements.

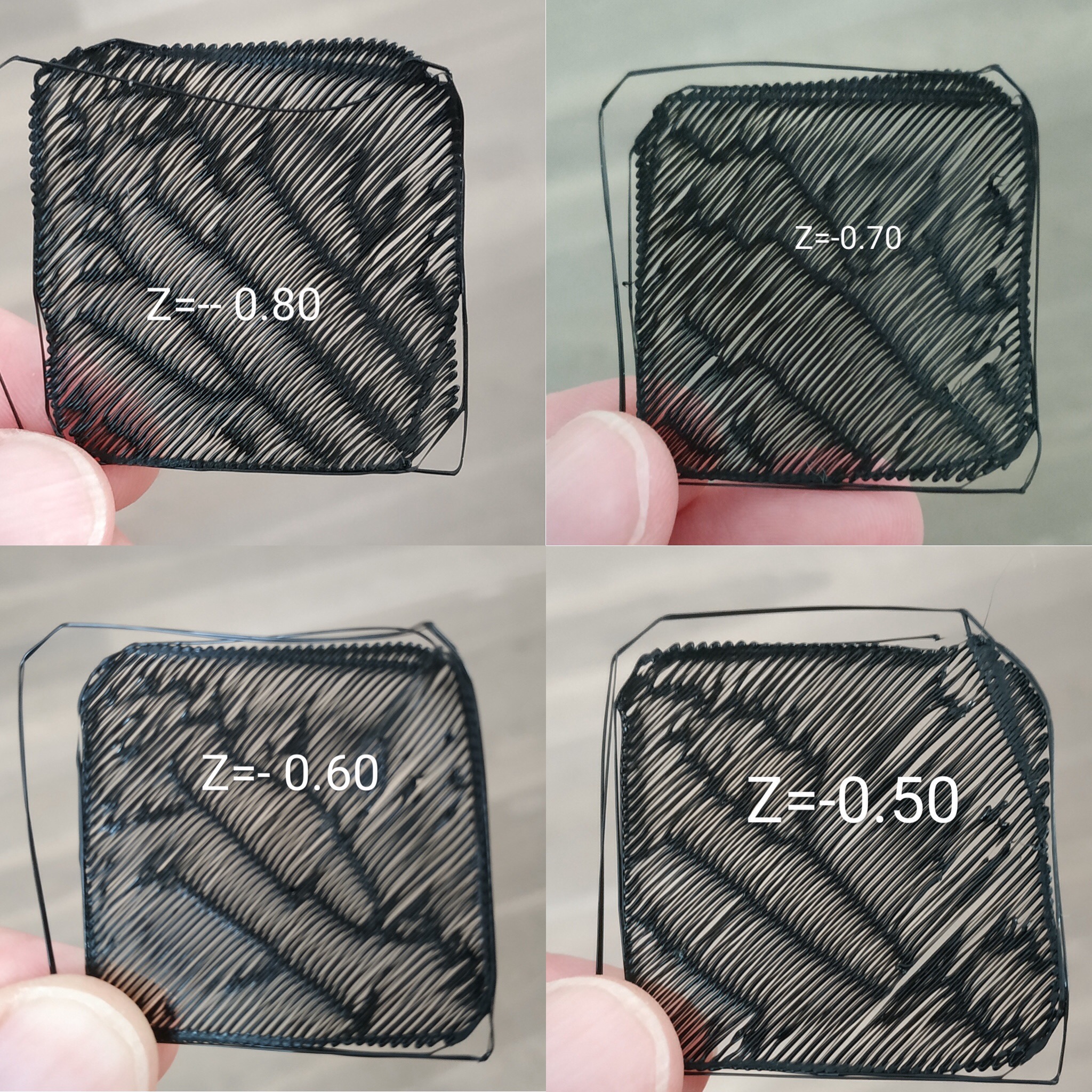

I've started to think that the squish is not the right one so I made a test: I've printed the first layer of a small plate (40x40mm) by changing only the nozzle quote from -0.90mm (Z live adjustment quote) up to -0.50mm.

As you can see from this picture it seems to me that the right quote is around -0.70mm:

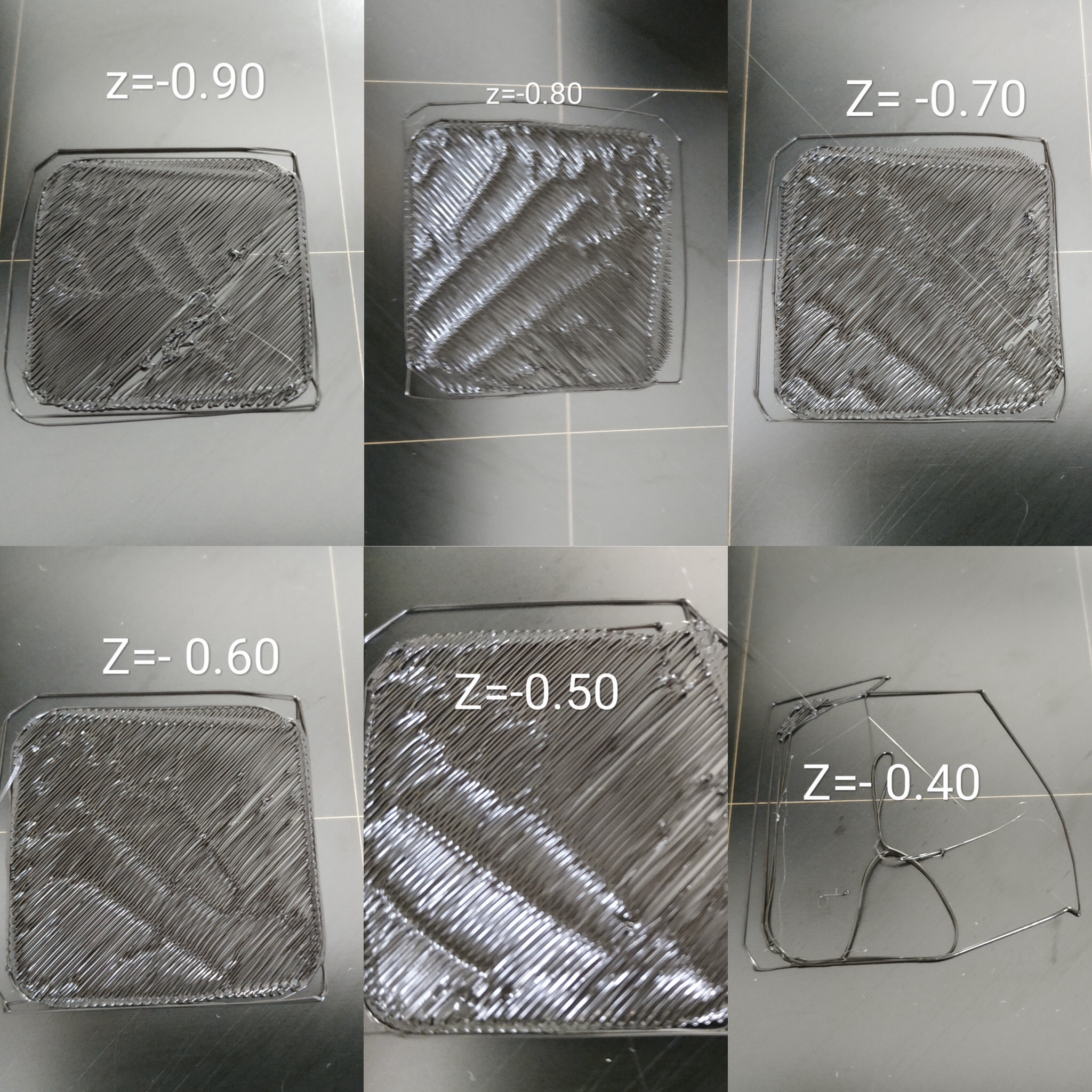

Here a picture of four samples out from the printing bed ( just to have a better view):

It seems strange to me that the PLA flow is not constant and I don't know if this is a problem and if it can reduce the adhesion.

I have tried to print the part by using Flex material (Flexfill 98A): the result is ok!

I have used some glue and the filament stick well to the printing bed.

But I need to print this part with PLA because Flexfill is too soft.

I'm sure I'm making mistake somewhere but I don't know how to fix this problem!

Thanks in advance for any tip and advice!

Matteo

Re: Thin and large PLA plate printing problem

Sorry but there's a double picture... 🙄

Re: Thin and large PLA plate printing problem

To my eye, all the photos show a live-Z that's too high, even the -0.90 one. I'd keep making the live-Z lower.

There shouldn't be large gaps visible between the filament lines. They should be fused together in something close to a single sheet of plastic.

Re: Thin and large PLA plate printing problem

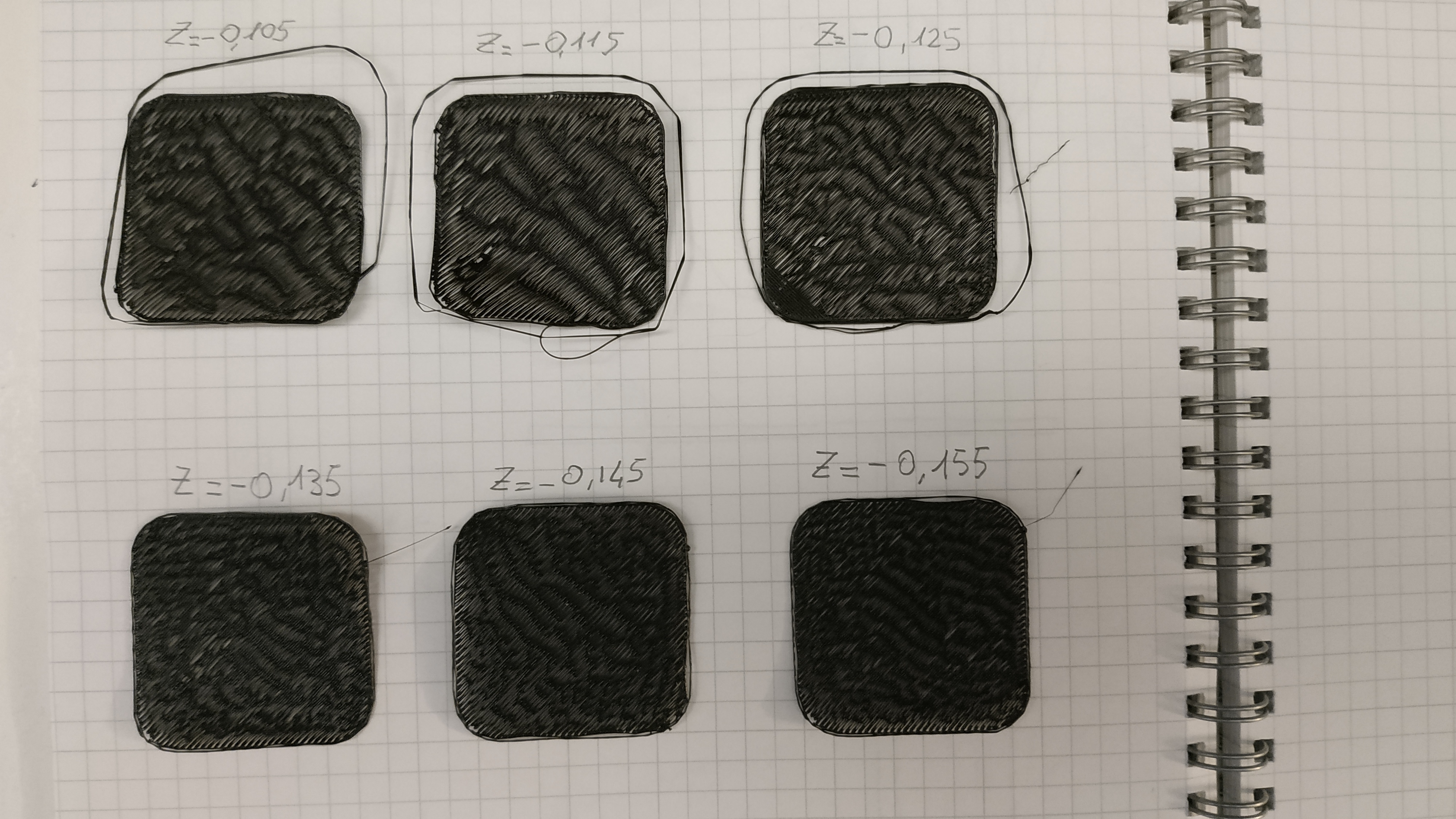

Thanks Peter! You are right: I was still to high and the filaments didn't glue at all even if I was able to print other parts whith a different shape.

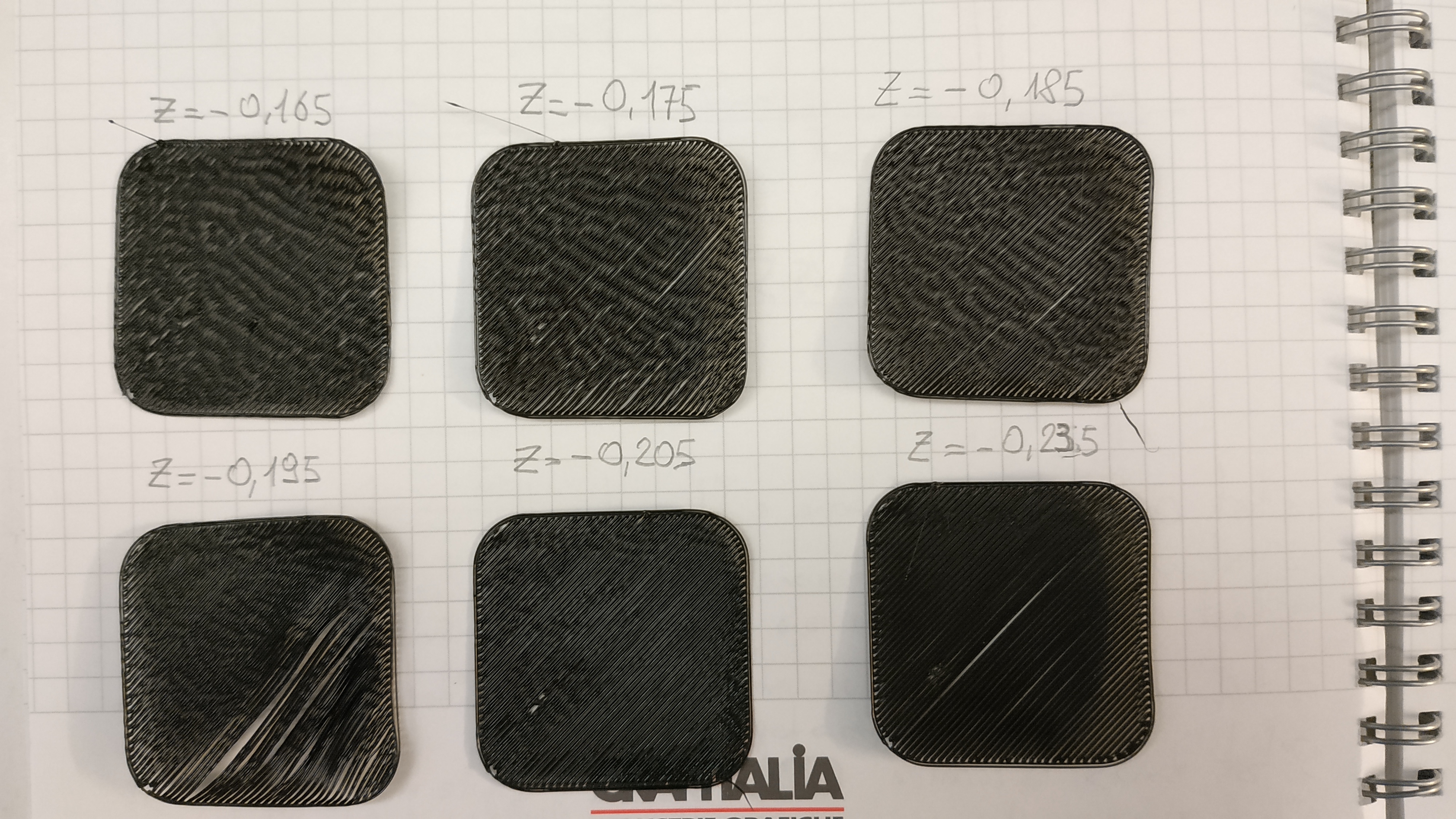

I took a picture of all the others samples I've made so maybe can be useful for someone else.

Here the first 6 samples I've made: I decrease the Z quote just 0.01mm per time:

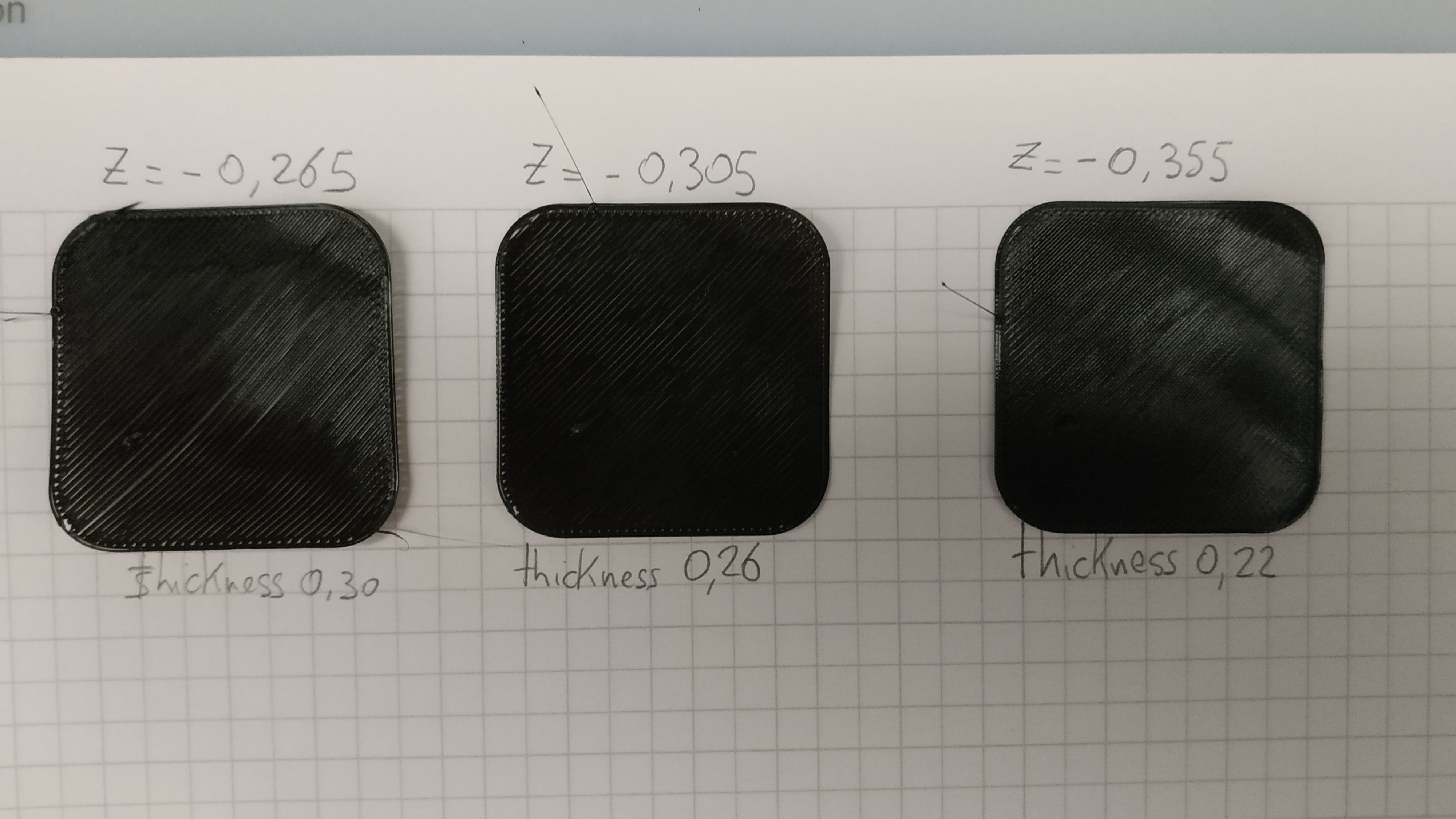

Here the second set of samples:

Here the last set: I've choosed -0.355mm and now I've started a trial print:

The last sample on the right is the one I've choosed: the filaments are glued together and you cannot see through it !

Matteo