Support and brim control

Is there a way to fine tune supports and brims in Slic3rPE? Nothing is jumping out to me, but this is all new to me still so many of the screens don't mean much to me yet and I'm still finding things as I go.

Last night I printed something where a few parts needed brims, but others did not. Similarly some areas needed supports while others did not. I'm running a much longer print now that has the same issues and have already queued up some additional slices that I'd like to do similar tweaking to.

Is there a way to turn the brim on/off for individual objects? Similarly is there a way to remove supports that I don't think the printer really needs?

Re: Support and brim control

print settings -> support and brim

multiple process support in slic3r is clunky and I haven't been able to figure it out, but I don't usually use slic3r.

Re: Support and brim control

Is there a way to fine tune supports and brims in Slic3rPE? Nothing is jumping out to me, but this is all new to me still so many of the screens don't mean much to me yet and I'm still finding things as I go.

Is there a way to turn the brim on/off for individual objects? Similarly is there a way to remove supports that I don't think the printer really needs?

Not sure about brims, but you can turn off supports for individual objects.

Search for "slic3r support blocker enforcer".

Re: Support and brim control

Slic3r now has

support enforcers and

support Blockers, available

and individual settings for individual items on the build plate

but there doesn't appear to be an option for adding a brim in the individual item settings

are you aware that it is often better to build supports into the model rather than use automatic supports!

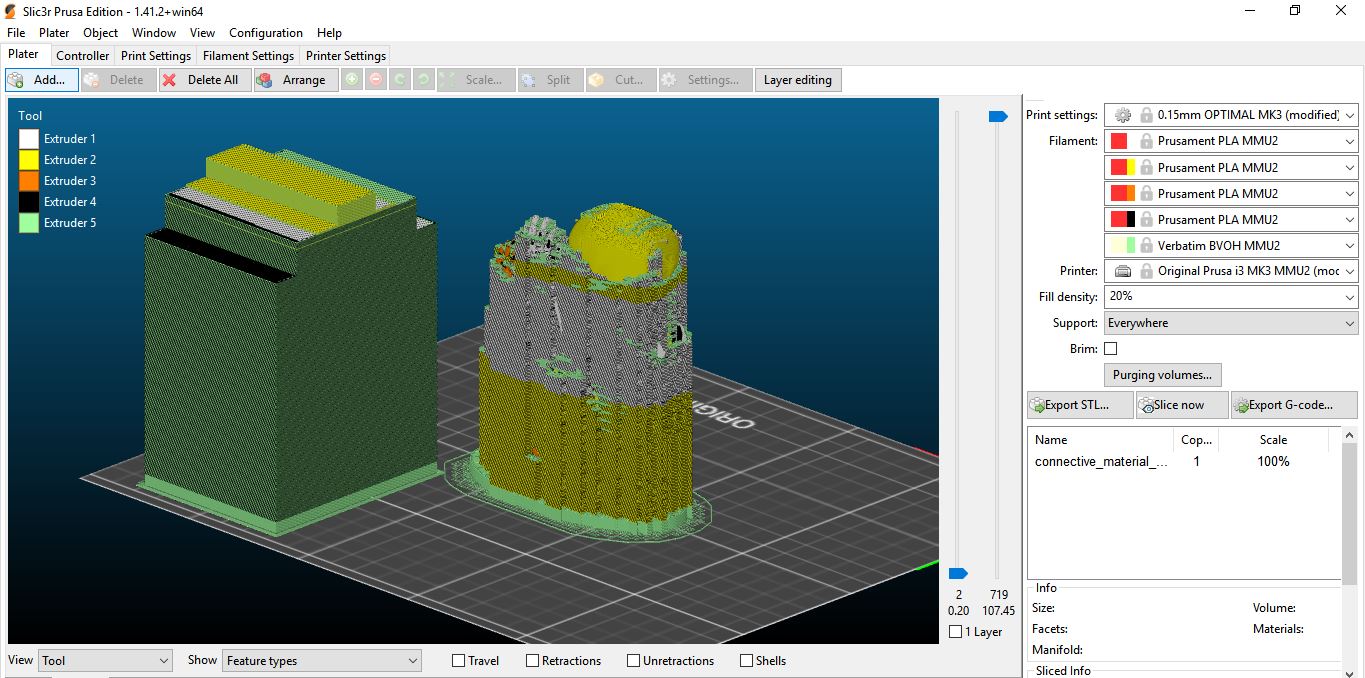

the model above is a multiMaterial model that has been 'Murdered by automatic supports

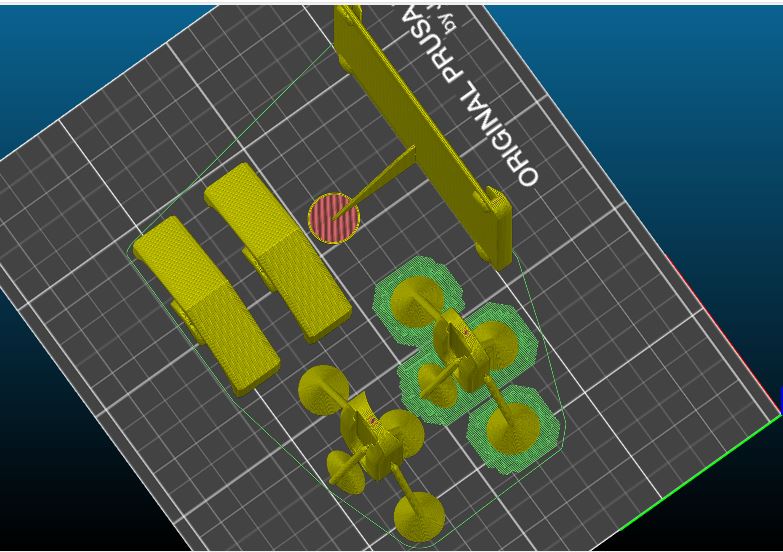

the models above have been designed to print without support,

note, the top model with the redish disc on the build plate, that is 160mm tall and 7mm by 100mm on the build plate, if automatic supports were enabled, there would be a tiny bit of support at the bottom rounded corners but thee would be no way that the model would print to full height, because there is too much leverage on the tiny contact area, the sacrificial blade and mouse ear foot, were designed to only contact the model in three tiny points, which would give support during printing and snap off easily, afterwards.

the two identical parts were designed for a tape dispenser, and they are intended to glue together

the other two irems, are tall and thin and have a curved surface on the bottom, automatic supports could be used but the bottom curve would be poor, so I have added two tiny extended walls to support the sides of the curve, this causes the slicer to 'bridge this area, which gives a better finish than same material supports, you can see I added space ship landing legs to give additional stability in the design stage, one of them has a raft, to show that you can add attributes to individual items on a multiple model build plate

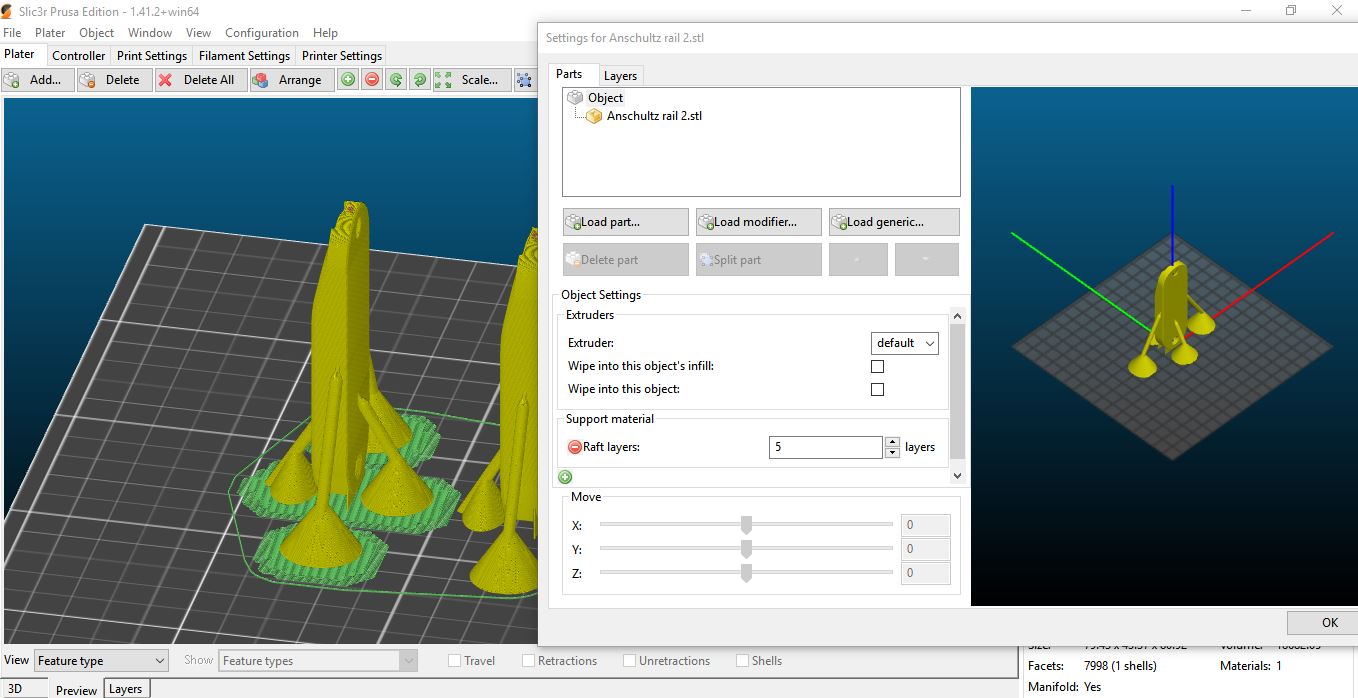

to access the object settings window, you can select the particular part on the build plate, (it will turn green)

then select the 'Object' drop down menu, then the settings menu, and you get a menu similar to above.

in this menu, you can ;

manage multi part models, including wipe to infill and wipe to model,

change many attributes of individual models (I added a 5 layer raft under one model)

import mesh modifiers,

create 'Lamda objects, and use them to enforce or block automatic supports, or localise attribute changes within a model,

the links below may help here

have a look and see if these help,

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Support and brim control

Thanks Joan for all the detailed information. So much to learn 😀

Yes I'm aware that designing to not need supports is the best option, but so far this is printing others work. I do have something I am working on and my preliminary slicing indeed shows it would ruin the piece without using PVA as there are areas you simply couldn't clean out.

Re: Support and brim control

you can often add custom supports to existing STL's

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Support and brim control

My problem is there are no supports where there need to be. On one object, there is a flat arm about 10mm off the platter. Its dimensions are about 15 x 100mm. The supports ring the edge, leaving 70% of the center with no supports. That will require a 70mm open air filament run. You can guess the results.

Suggestions?