Super fragile print, calibration problem or Slicer setting?

Hi,

I recalibrated the printer (stupid mistake) and after that the print came out super fragile. Previous prints were sturdy…

I used "0.2 mm speed" and only 5% infill. But it has worked good before.

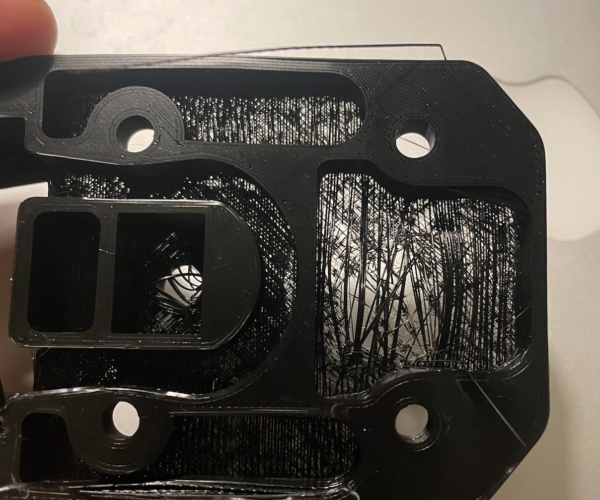

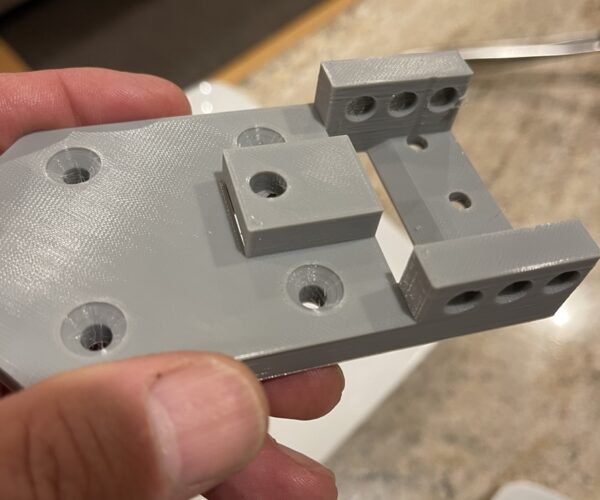

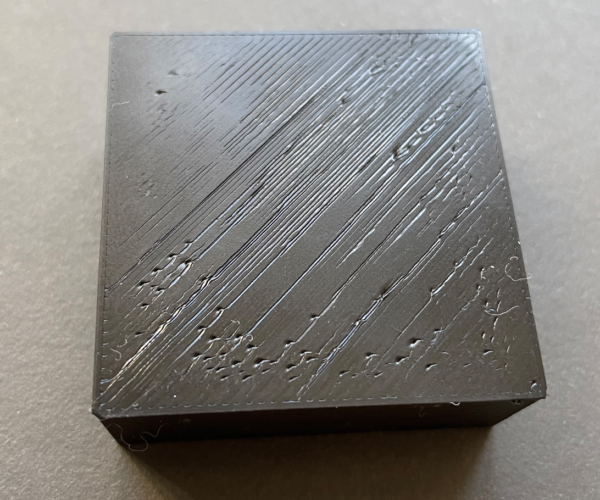

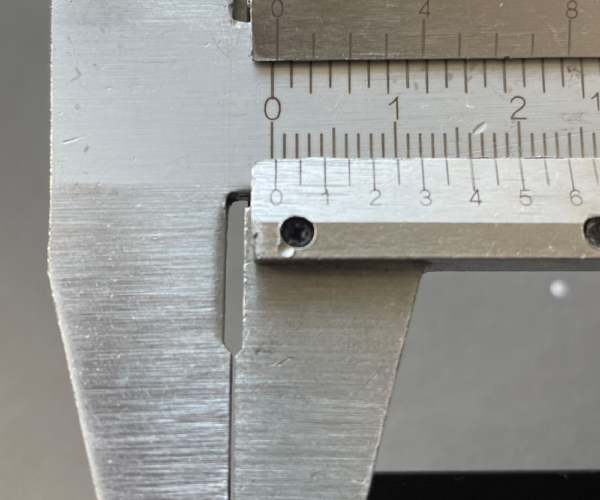

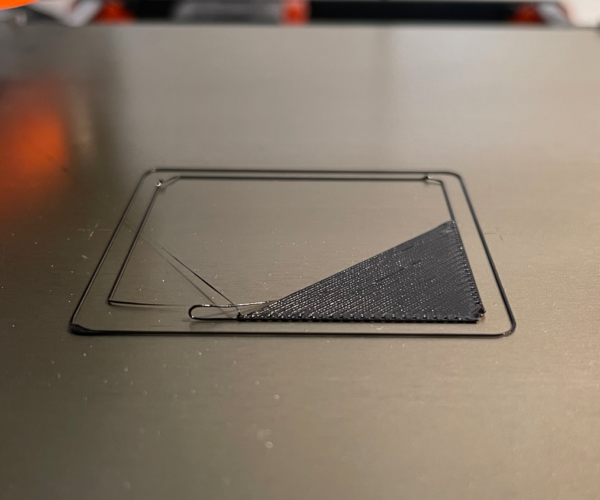

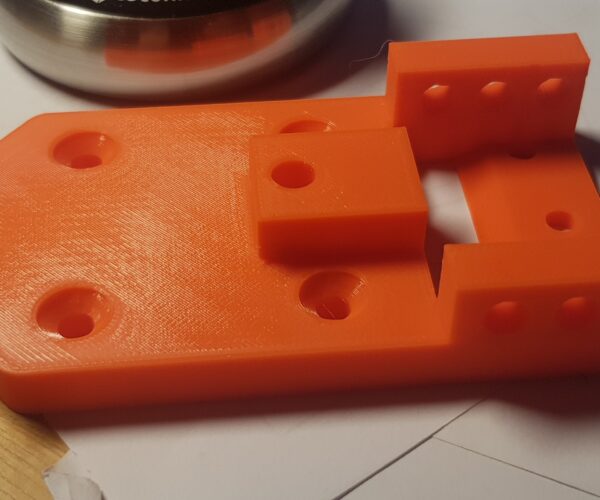

The top layer (see first image, top layer is facing down on the image and looks like a spider web) is 1-5mm thick in the design but transparent on the print. I know im printing that layer in the air, will use support .

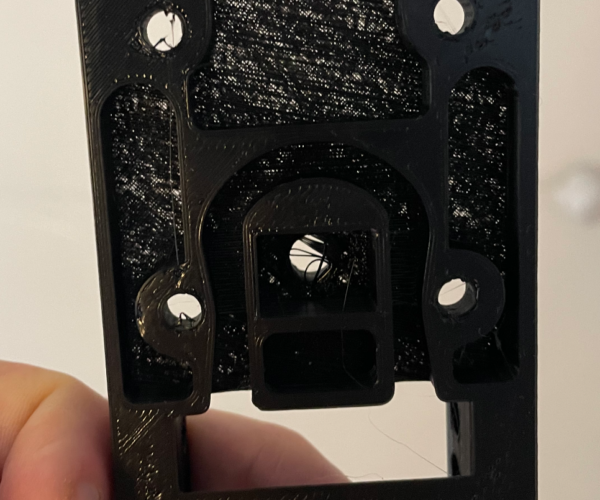

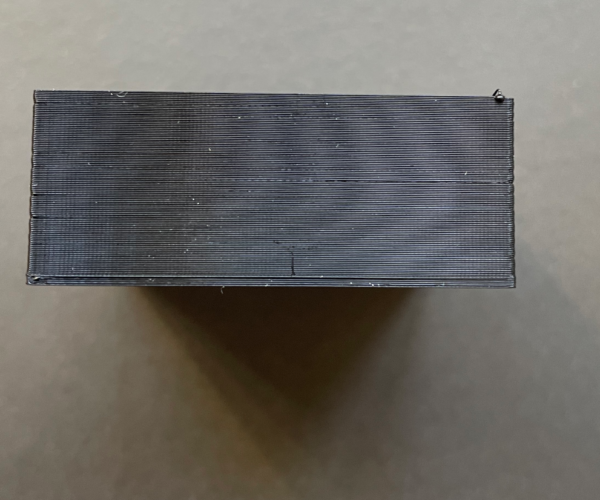

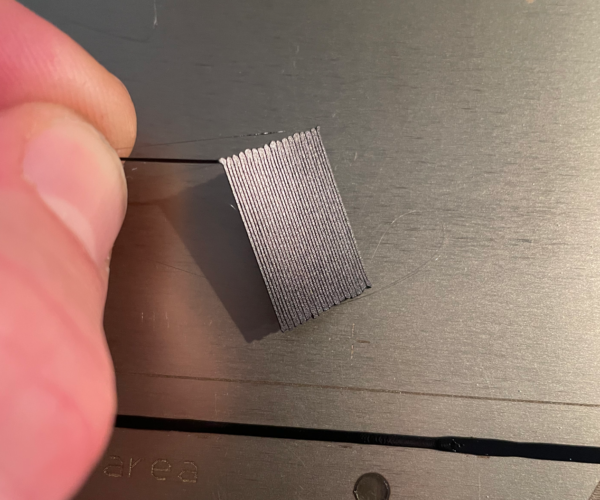

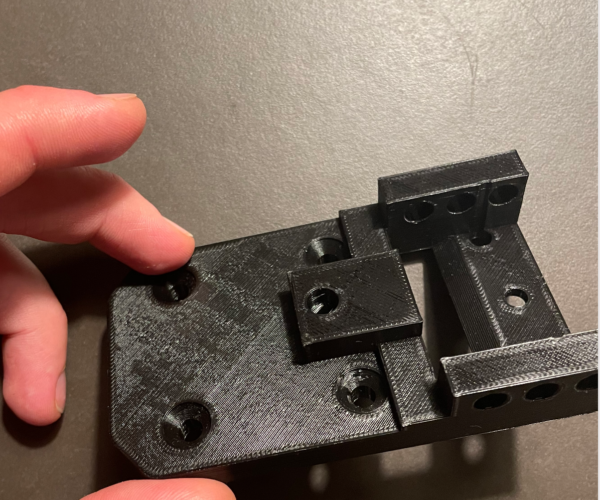

On the other image I squeezed the part with my hand, would not be able to do that with the previous prints.

Please note that the first layer is the side facing up on the first image, and it looks pretty good?

Is the Z-axis wrong?

Best

Rule number one in such case: use default settings in slicer and print again. Your first layer seems to be ok and has nothing to do with your trouble.

You might get better help if you provide 3mf file of your sliced object.

[Mini+] [MK3S+BEAR]

Save your project from the Files menu as a 3mf. Zip it, or you won't be able to upload it. Then post it here so we can see the STL but more importantly your setting.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Superficial appearance

I agree posung a zip of the .3mf will be the way for people here to sort out your problem.

However, just looking at the print, after the first layer, you appear to have terrible interlayer cohesion and under extrusion, so things to look at are hot end temp and flow rates.

As people have pointed out, without the .3mf this IS NO MORE THAN A GUESS!

Images + 3mf

Thanks for all replies!

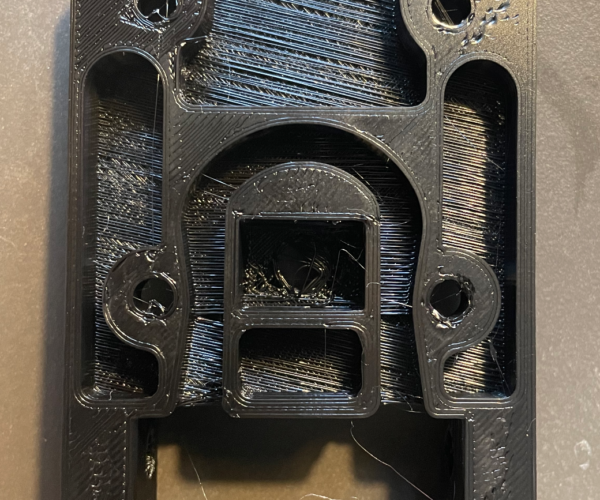

I reprinted with 0.15 20% (prusa preset). have the same experience (slightly stronger…)

Have attached

4 images

1 .zip with 3mf

RE: Super fragile print, calibration problem or Slicer setting?

@chisburg

Your file with "0.15mm Speed, Prusament PLA, Original Prusa MK3S & MK3S+", all standard settings

Filament I use was Prusament PLA that has been out of bag for at least 1 month, probably closer to 2.

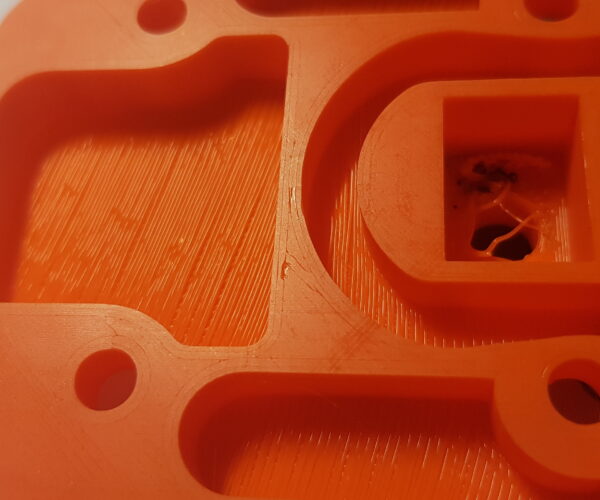

The hole in the middle is printed in mid air, obviously there is a problem with that 😏

Bridges could be improved with some support

Overall it looks descent on the (I assume) outside, and is sturdy

Filament on your pictures looks a little glossy, are you sure it is PLA? I've had wrong filament loaded, more then than once... 😔

Did you print a single wall test cube for flow rate test?

Is it just this print that failed?

21-ch_0.15-Speed_Prusament-PLA_MK3S+_Ringarn67.zip

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

Recalibration

Hi!

looks great. It looks the same as it did for me before i recalibrated. Im 100% sure im using PLA, and it's the same PLA as i used the day before i recalibrated, see the image below.

I guess something is wrong in calibration then?

Let me do an other test print, the single wall test cube — is it a prusa standard test?

@chisburg

Look for "Precise Method" on this https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257 page

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

@Ringarn67

Thanks, step 3 to 5 needs som head processing… I cant understand it, perhaps it's because it's getting late.

Couldnt my issue be a z-axis problem, and should i lower or go higher?

Extrusion multiplier

You can print the cube and just take the average of your measurements. If your average is .45 or close to .45 then the default multiplier is good and we'll know the problem is elsewhere.

Mk3S+,SL1S

Extrusion multiplier

Got it, will put it on print tomorrow!

Thanks

Another example:

Apart from the hole in thin air that @ringarn67 has pointed out, I think the bridging is actually as good as it gets. Not sure supports will make a huge difference.

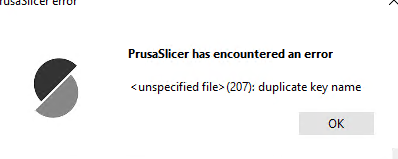

I did notice a few weird things though. I can't load it into PS 2.4 alpha:

I can load it into 2.3 but loads with the Original Prusa Mini & Mini+ printer profile and ABS filament profile selected. If this is the profile you were trying to print with, I'm not surprised. When I try to switch to Original Prusa i3 Mk3S & Mk3S+, I get another warning "Preset Prusa i3 MK3 has the following unsaved changes". Why "Mk3" and not "Mini & Mini+", I don't understand but with the duplicate key name error, I'm wondering if there's something not quite right with the 3MF file.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

@fuchsr

There is some weird things going on in PrusaSlicer 2.3 if the presets used in 3mf-file, in this case "Original Prusa i3 MK3" and "Prusa PLA" is not installed.

If presets is not installed PS choose the first preset name it can find, in your case "Mini & Mini+, in my case "Anycubic Kossel...."

Same for "Prusa PLA", I have it installed so PS shows it. I guess you haven't, so PS shows first preset in your list, which I guess is "ABS filament".

If you look at "Dependencies" in filament and printer profile you will see the "original" presets

I have "Anycubic...." installed for just this reason, if PS on my machine choose "Anycubic...", I assume the 3mf's preset is not installed on my computer.

This is a bug and it is fixed in 2.4 👍

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

Good to know. On the other hand, it didn't load in 2.4 at all for me ☹️

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Yeah 2.4 just errors and then wont load it due to the duplicate key. If you open it in 2.3, then save it again it does open in 2.4. At least it did for me.

Duplicate keys are usually an indication that theres something wrong with the profile(s) on the original computer though. There was a bug awhile ago in previous versions where you could import a profile (say from an internet site) that was malformed with xml keys belonging to different sections due to how the profile had been created. On the surface it looks perfectly fine and works but it could do weird things, like always using a certain setting for example no matter what you configured in the software. This was because you were changing the setting/key in the 'proper' place but the duplicate that was stored in the wrong section couldn't be edited and if it was later in the list then it was used.

I was in fact wondering if somehow the OP's configurations got screwed up, which may lead to what he's seeing.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Re-did everything

Ive restarted it all,

1. updated Slicer

2. Updated firmeware

3. removed and cleaned nozzle

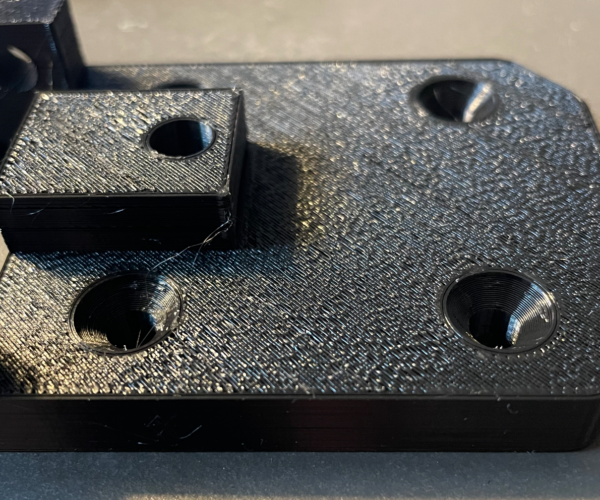

4. recalibrated (looks good now, or is it too low?)

The new problem now is that fillament is sticking to the nozzle. tried to film while printing the cube…

@fuchsr

Yes, his settings file was corrupted!

Unzip his 3mf-file, (rename it from 3mf to zip), open "Slic3r_PE_model.config" and look at line 95 and 209, both lines says

"; printer_model = MK3"

Guess "(207)" means line 209 in config part of file, (two kind of empty lines in the beginning of file)

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

@chisburg

Go lower 👍

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10