Stringing horror

Hi there,

I've got my i3 MK3S back in august 2019. Since day one, I've run my printer and used Prusaslicer with every settings stock and no hardware upgrade.

For a long while, I've knew I had stringing issue with my printer. I tried tweaking my Prusaslicer settings once, base on a Youtube video. It worked great on a stringing test print but the overall qualities of my prints really suffered so I turned my settings back to stock. Since the stringing was not that of a issue, I did not feel the need to try fixing this problem again. Until today.

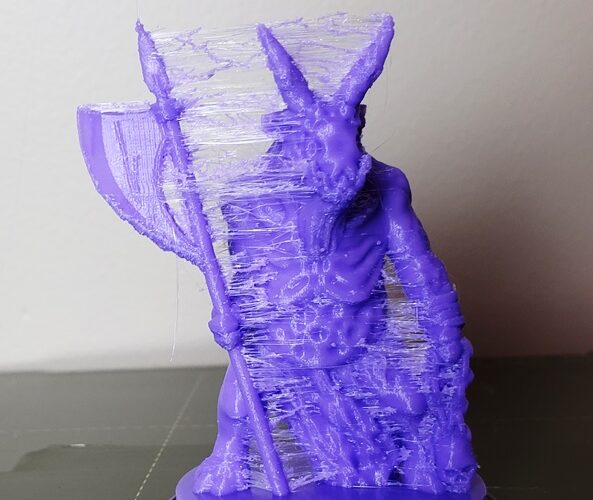

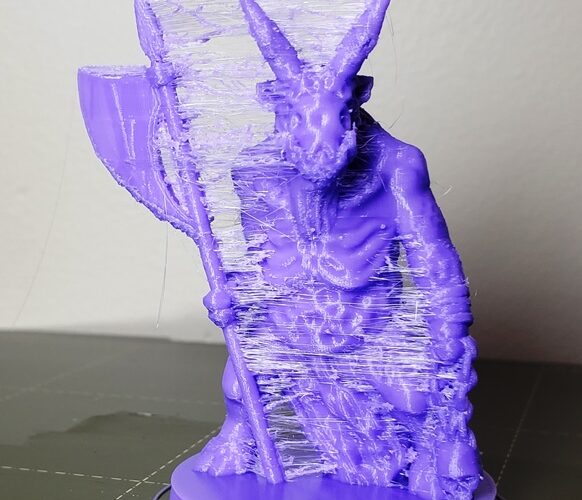

I got the idea to print a miniature figure. I know that it's not what FMD printers excels at. And that I was not helping myself by using a 0.40 mm nozzle. None the less, I add few pretty good previous experiences printing "mini like" stuffs. So, I chose a nice, low details, supports free, FDM friendly model that I scale up to 150%. I slice it at 0,05mm with vertical shells perimeters set to 1 and started to print it no long before going to sleep, knowing the print would be ready when I woke up. And I woke up to this:

I think the model print well but it hard to tell because of this freaking stringing horror mess! 😳

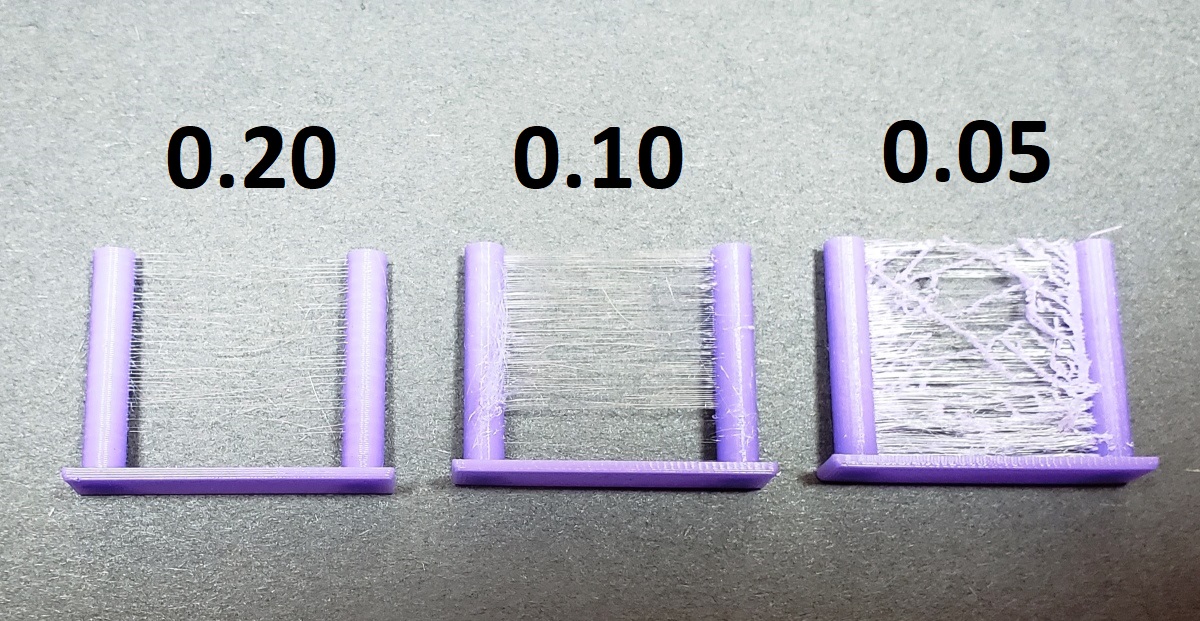

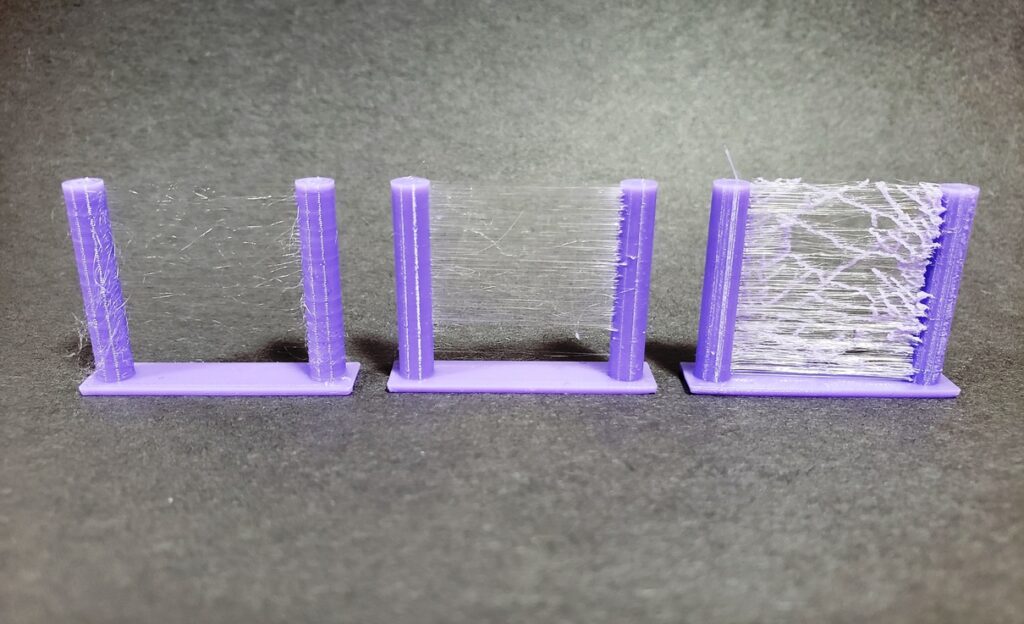

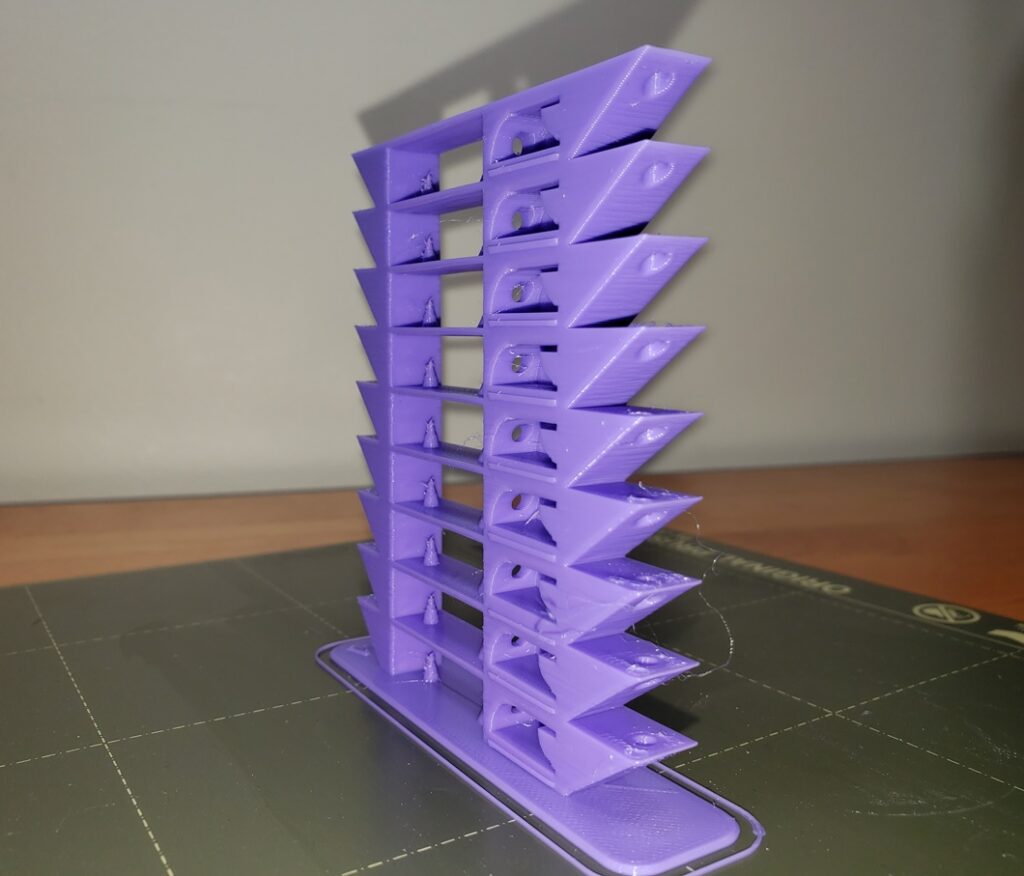

I rarely print at 0,05 and never before I was face with such a stringing issue. I've printed three stringing tests files, at 0.20, 0.10 and 0.05, that confirmed the obvious.

Before I forget, all these were print using AMZ3D PLA filament. This brand have always print very well for me and I almost only print with it.

So, how can I fix this stringing issue without compromising the qualities of my prints?

Thanks for your time. 🙂

RE: Stringing horror

Going below 0.1 is pointless with a 0.4 mm nozzle. I'd dry the filament thoroughly, run a stringing test/temp tower at different temperatures and pick the lowest one feasible, and make sure my filament is dialed in properly a la Bob's https://projects.ttlexceeded.com/3dprinting_techniques_calibrating_filament.html

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Stringing horror

If this happened to me, the first thing I would do is compare that particular spool of filament, on a stringing test, with a spool of filament I knew to be good.

My guess is that the filament is damp, and that drying it will most likely help.

I also agree on the admonition to not OD on fine resolution. I've found that once you get to that 0.15 level, reducing it more has little visual effect on the prints and, of course, takes up time.

RE: Stringing horror

Thanks for your answers fuchsr and jsw, really appreciated.

So, I've order a food dehydrator to dry my filament before a run any further test print. Once this is done, I will print a temp tower and, if needed (probably), I will delve into the "a la Bob's" filament calibration.

Also, a big thanks for pointing out the limits of a 0.4mm nozzle in regard of the print resolution. In the same time, I feel really dumb and lazy for not knowing this. 😶 😋

Speaking of dumb, a side question: I've heard a few days ago someone saying that you should change a printer nozzle "after a few hundred of hours of print time".

I really "hope" this is not true because I'm running the same stock nozzle that came whit my printer from day one and I've accumulated over a hundred of days of print time so far... 😳 😶 🙃

RE: Stringing horror

The stock brass nozzles do wear, and using things like metallic filaments will cause them to wear more quickly.

'A few hundred hours' is probably a good ballpark number at which to swap out the nozzle.

Some time ago I ordered a tungsten carbide nozzle and swapped it out when I had the printer down for something else, and it's been running fine ever since.

You will need to re-do all of your Z calibrations, or at least check them, when you swap out the nozzle.

RE: Stringing horror

What jsw said. As far as nozzles is concerned, brass nozzles are dirt cheap, so keep a few around. Until recently I preferred nickel-coated copper, because — without rigorous scientific proof — they "felt" to work better with PETG, which I print a lot. These days I run all my printers with tungsten carbide nozzles, so I don't have to worry about abrasion. I also tried hardened steel (nozzle x) but at least in my hands it required adjustments to printer profiles, whereas tungsten carbide works fine with my standard settings. But they're expensive.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Stringing horror: Revange of the Dehydrator

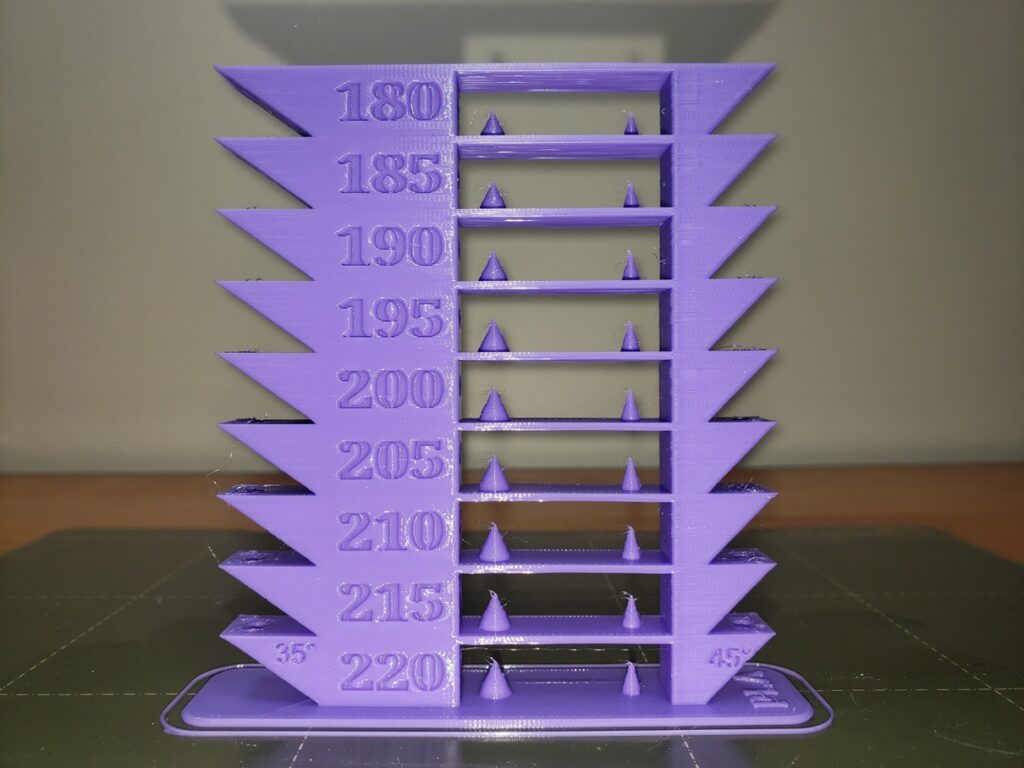

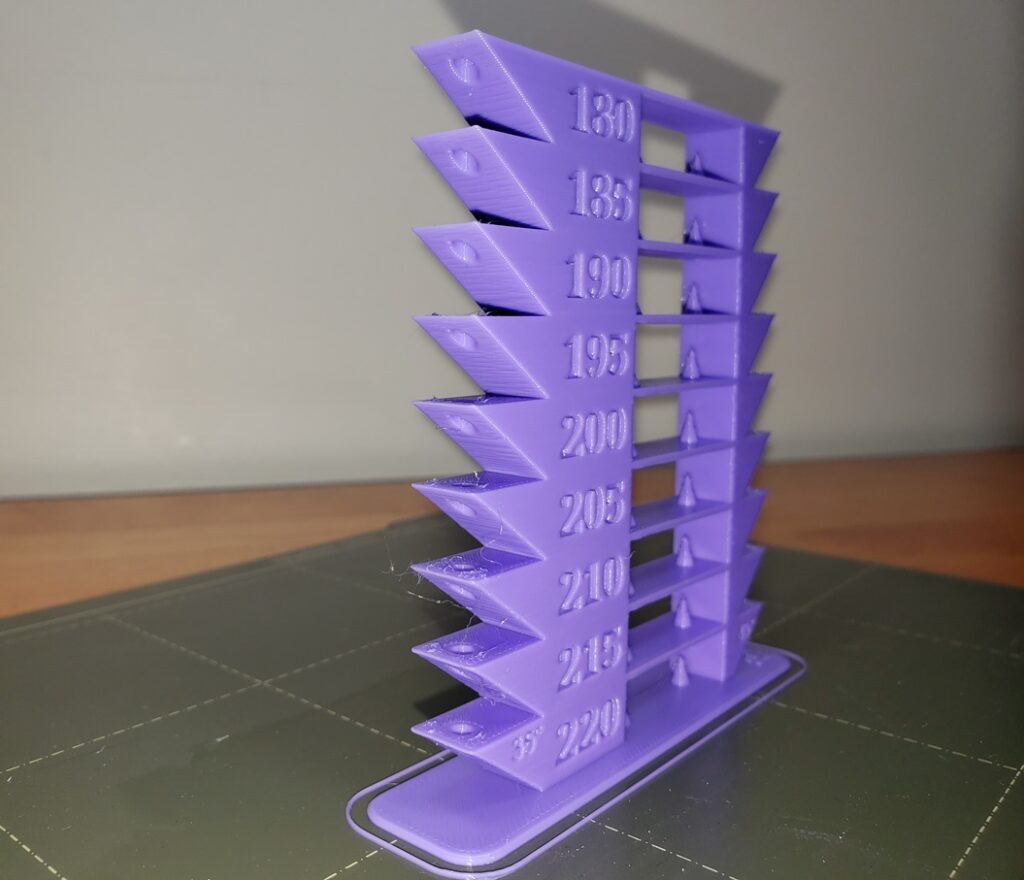

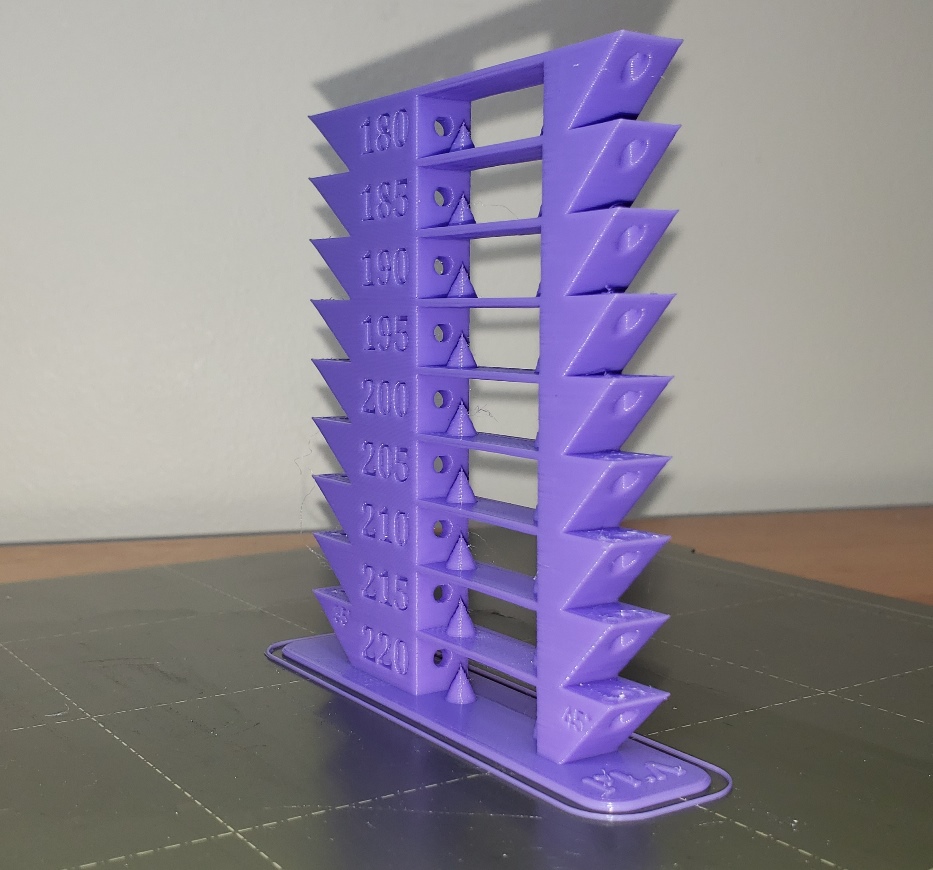

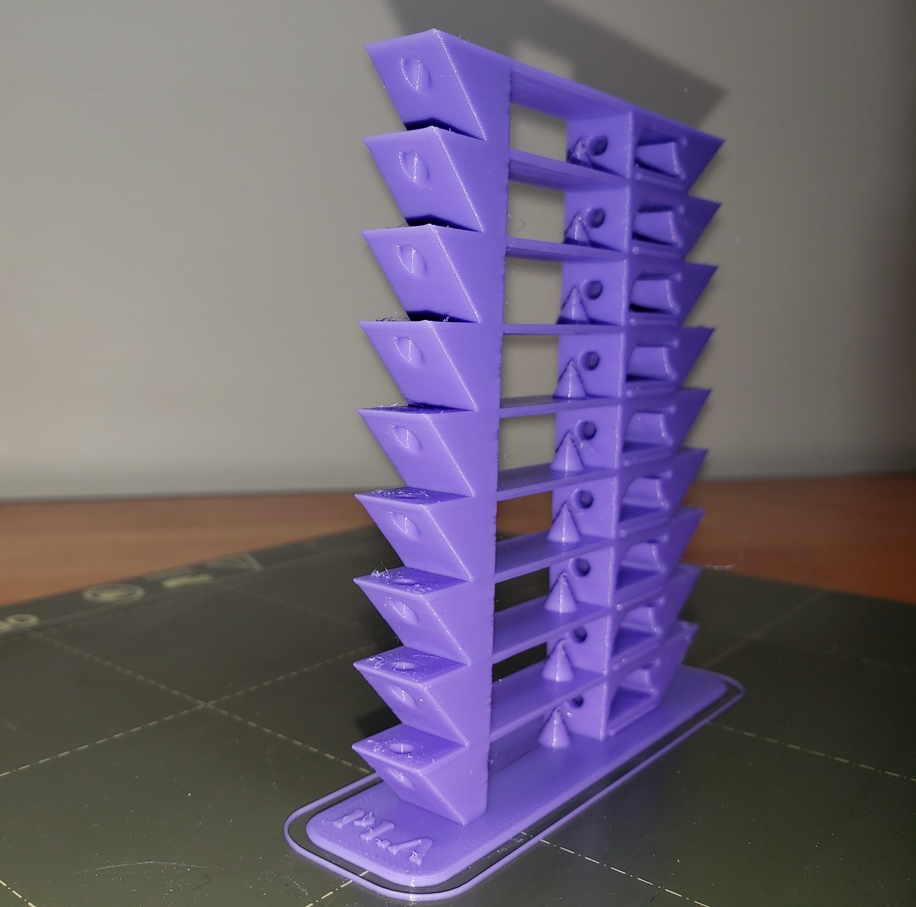

As plan, I got a food dehydrator and I dried my PLA roll for a solid 12 hours at 45 Celsius. Next, after some looking around, I printed a remix temp tower from fuchser (😉 ). Here the result:

Not much stringing here. There is two complete strings at 220 in the middle, nothing else at any other temp. Beside this, I don't know what to really look for, since everything seem to have print the same at any temp. One thing I notice is how solid the bridging is. I don't recall my printer doing so well with bridges.

And this was printed whit my worn out nozzle ( I got a new one but still have to swap them).

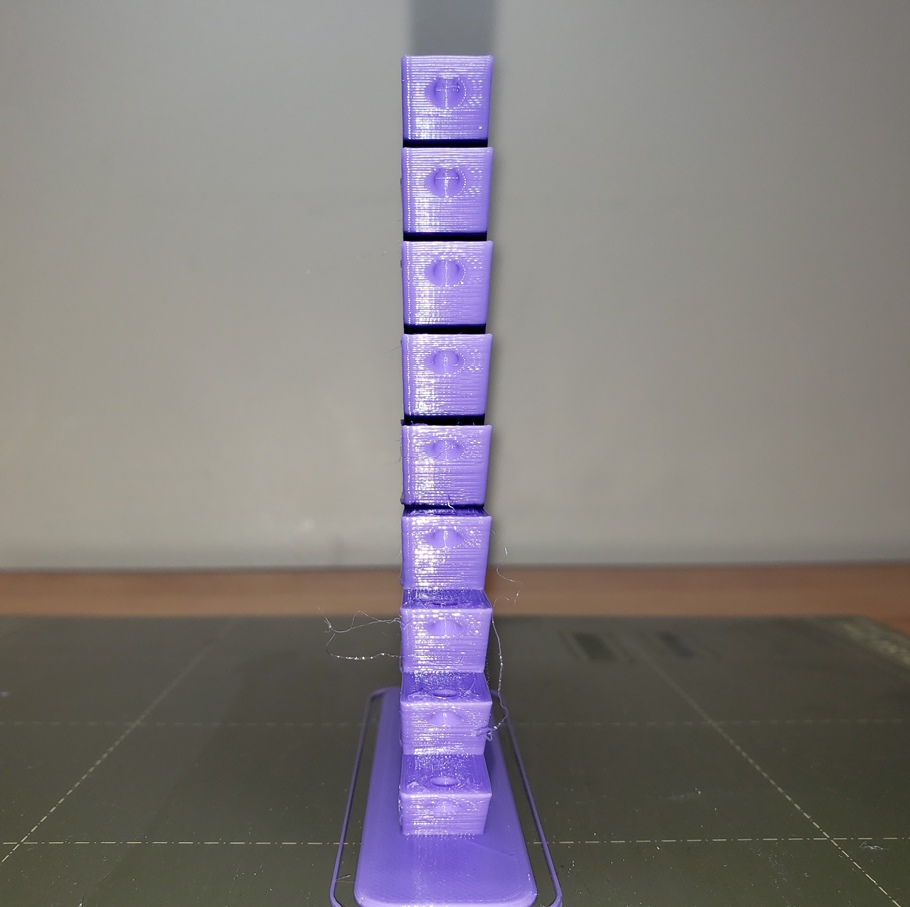

Seeing how the dried filament was performing, I reprinted the figurine, at 0,10mm this time, and the difference is spectacular! Those pics were taken after I've already remove about 50% of the stringing on the model. The stings were very easy to removed.

So, what should I learn from the temp tower, beside that dry filament is a solid key to less stringing?

RE: Stringing horror

Not alot. Those really fine almost spider web strings are easy to remove with a blue flame lighter. A really quick pass and they shrivel right up. I wouldn't be worried about them at all.

Classic textbook illustration of how much difference drying filament can make.

Personally I always print as hot as I can go without excessive stringing/overhang issues/bridging etc. Layer adhesion is better and the increased flow through the nozzle means less chance of a skip on trickier parts of models. From that tower then I'd happily print at 210-215.

RE: Stringing horror

A heat gun is also a nice bday or xmas present! A swipe or two, and all cobwebs are gone. Most quality filament appears to work pretty well across the whole temperature spectrum these days, good thing.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Stringing horror

...actually that's a darn good print... how tall's the figurine?

RE: Stringing horror

Not that small. Nearly 70mm tall, the base is 4,5mm thick.

Got this model here: https://www.thingiverse.com/thing:4598897 . I chose it because it's support free and it don't have to much intricate details. And also, because I think it look cool. 😉 I've modified the axe (longer shaft and bigger blade) and I've printed it at 150% from the original size. For comparison, I took this pic, side by side, with a regular Space Marine figurine from GW (with unfinished paint job).

As for the print itself, I did nothing special, I just used the stock settings. Took 4h16 to print at 15% infill.