strange line wont go away

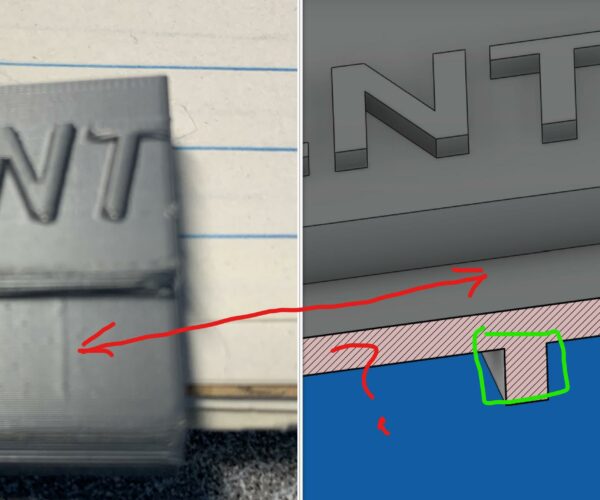

Two 3d Prints in a row my MK3S decided to print this line that oddly is in line with a lower extrusion that ends inside the green box. What can I check? The fusion 360 group is telling me there's nothing wrong with my design.

Here's a cutaway:

And if you want here's a small 3mf of the problem area from my google drive:

By the way I know i have an overhang issue. This print was just to see what' going on with the line. I print with .15 Quality.

thanks for any advice.

RE: strange line wont go away

Post the file on the forum(zip it first). Google and dropbox usually break and the links disappear making the post useless.

Without looking at the file you are probably experiencing print through. Minor over or under extrusion will show through several layers. Increasing the top layer thickness helps, maybe ironing.

RE: strange line wont go away

Here's a zip of the 3mf file. The layer this is printing on is an outside layer. Ironing would probably significantly slow the print down. The file attached is only a small sliver of it for testing.

Any guidance would be appreciated. My printer is less than a month old and I'm still getting my bearings with the settings and anomalies.

RE: strange line wont go away

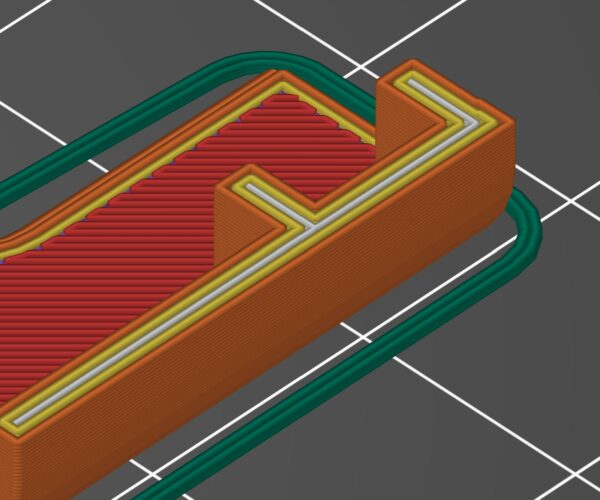

Looking at the part I think this is just an extension of the known bulge issues in slicing. Slicer has always had this nasty habit of adding too much plastic at certain transitions that leave an artifact in the outer wall. Setting Detect Thin Wall sometimes helps, changing the wall depth to the values Slicer recommends (under the vertical shell entry), and slowing the print speed down. But this feature looks a bit different than what is normally seen. Here's an example of the common bulge issue and many attempts to tame it:

You might try tuning the extrusion multiplier to match your filament; and there's a slight chance K factor is off for your extruder.

https://help.prusa3d.com/en/article/extrusion-multiplier-calibration_2257/

https://help.prusa3d.com/en/article/linear-advance_2252/

https://www.prusaprinters.org/prints/39968-la15-k-factor-calibration

It may come back to the slicer - you might try using Cura - others who use it say it seems to handle these bulge cases a little bit better.

ps: in all the attempts, and there have been many who have tried, there's never been a one-size-fits-all solution. Each case requires it's own method of reducing the issue.

RE: strange line wont go away

@jimerb

Your problem was one of extrusion width and can be solved in this case with a height range modifier, with adjusted perimeters. attached is an example .3mf of the settings I used to correct this blemish.

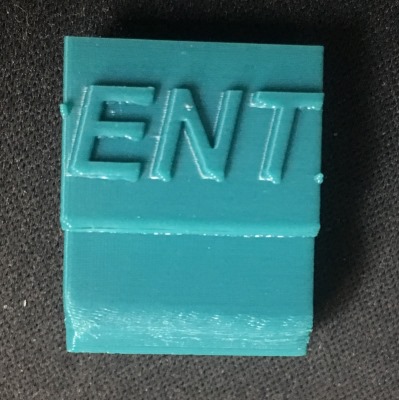

I printed an example, all be it out of ABS because that's what was loaded at the time so mine looks a bit droopy on the overhangs because the part is small and had lots of heat build up I made no attempt to correct this because the area that your blemish exists would print fine, the part that was impotent is clear to see.

using these settings on the full model should alleviate the problem, but of course I don't really know because I only have this small sample to go by.

Best of Luck

Swiss_Cheese

The Filament Whisperer

RE: strange line wont go away

@swiss_cheese

Hey Swiss - I'm curious - did you simply measure the wall thickness there and do the long division to pick the 0.52? Or did you use some other way for choosing that specific value?

RE: strange line wont go away

@swiss_cheese

Great! Thanks for doing this. I'll check it out.

RE: strange line wont go away

@swiss_cheese

Very interesting. You should do a tutorial thread and post it to the prints section.

--------------------

Chuck H

3D Printer Review Blog

RE: strange line wont go away

@swiss_cheese

Hey Swiss - I'm curious - did you simply measure the wall thickness there and do the long division to pick the 0.52? Or did you use some other way for choosing that specific value?

More important then how I came up with the width I used, is why I changed it in the first place. the answer to that question will also help answer your question.

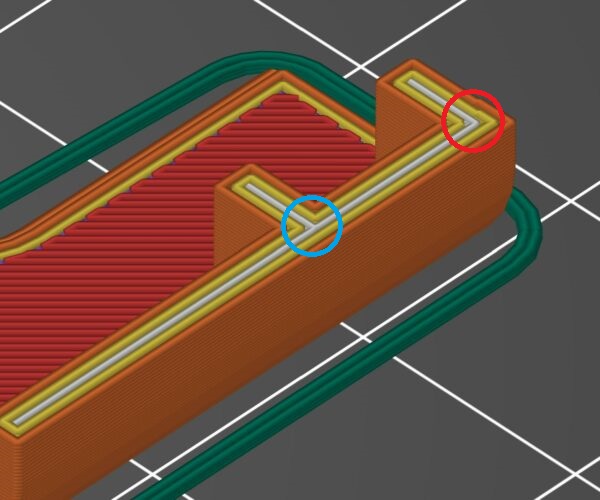

I changed the width in this instance to eliminate the "Gap Fill". Now lets be very very clear here, Gap fill is in no way (inherently) evil or even a trouble maker, it preforms a function and has legitimate uses. with that said any over abundance of material in an area is going to cause these kind of problems. I've mentioned this numerous times in other posts that no one pays attention too, in slicer the Gap fill area marked in Blue is showing a nice smooth line all on one layer (it looks so clean and predestine) But it's not. It's filling that area with almost twice the amount of plastic needed, slicers don't just butt lines up nice and neatly and stop extruding, even if they did your extruder won't, unless you make it 😉.

That extra plastic isn't going to cool the same as the surrounding perimeters as it and they shrink, you end up with a non uniform shrinking.

This isn't a problem with slicers or printers as a whole, it's a problem with users not understanding the material they are working with and the potential for control they have over it with that understanding and good slicing software. <--This comment was not intended for Tim, but rather new users of the point and click generation.

The area marked in Red does not exhibit this problem it's a simple corner, in this instance the extruder lays down the filament to the end of the path, retracts with a tiny bit of room to spare, and moves on to start the next movement. had the OP not cut the model there, there is a high likelihood that the same problem would have occurred in that area also.

In this case the blemish is removed by outright removing the cause in the area its occurring, I can off the top of my head think of three different ways I could have fixed this, and I chose the one I thought would most benefit the OP's model, as I understood it, form the tiny little sample provided.

I hope this Information helps someone,

Swiss_Cheese

The Filament Whisperer

RE: strange line wont go away

@swiss_cheese

Thanks for the detail - and I'm not as sensitive as you think; I take criticism fairly well. Don't like it, but I accept it and try to learn. lol.

So your thinking is the gap fill is doubling up on the T intersection. It makes sense and explains the hump in the perimeter. Sort of. I am still a bit perplexed anything a couple perimeters away would have that effect - but can't argue with the logic and outcome in this case.

It strikes me that any solution is going to be spot specific; almost like playing whack-a-mole.

Then there's the nagging fact that I have cut open test pieces and proven these bulges are not always bulges, but are offsets in the entire wall. An artifact that is a lot harder to explain but coincides with nearby changes in interior structures.

More research needed ... sigh.