still problems printing PETG/t-glase

I am still struggling with the t-glase. After solving the over extrusion issue thanks to some really helpful suggestions here this new issue has arisen.

The part is a torus segment of which I will need 24 that will eventually form a ring. Constructed with F360 and sliced with Prusa Slicer as well as with cura. The best iteration so far is 2 perimeters and 0% if. The part should be as translucent as possible. Single perimeter made it not stable enough. It is printed upright so the offending section starts at 98mm above the bed. Layer height is 0.3mm to achieve translucency (less created a milky white appearance). Temps are 245/95 at the upper end of the recommended range. Initial attempts at 240 degrees yielded worse results. Reducing either layer height or introducing up to 15% infill for the narrow bit made things worse (the top bit got so twisted it looked like a thread).

It looks like the layers are slipping of the previous layers, which seems odd to me.

Thanks in advance for any thoughts.

RE: still problems printing PETG/t-glase

That looks like it’s getting too hot. I think you have 2 options to try, either change the slow down if print time is below xx time under filament settings, I’m not at my pc at the moment but iirc it’s around 20 seconds, reduce it down to 5-6 seconds so it doesn’t spend as much time in one spot. The other option is to print more than one so that the print layer can cool slightly while it’s printing another.

If you cut to just leave the top of the model you can test out what works better without printing out the full length.

RE: still problems printing PETG/t-glase

Thanks for the quick reply, reducing the speed helped a lot. Still not perfect but good enough I hope.

RE: still problems printing PETG/t-glase

There is a setting that Neophyl mentioned which is minimal layer time - I think it is under the Filament Menu> Then Cooling? Like stated above the default is 20 seconds, but you can lower that to suit your needs.

Rich 3D

https://3dnewb.com

RE: still problems printing PETG/t-glase

@rich3d

I reduced that to 5 seconds and that gave quite acceptable results for the thinner part.

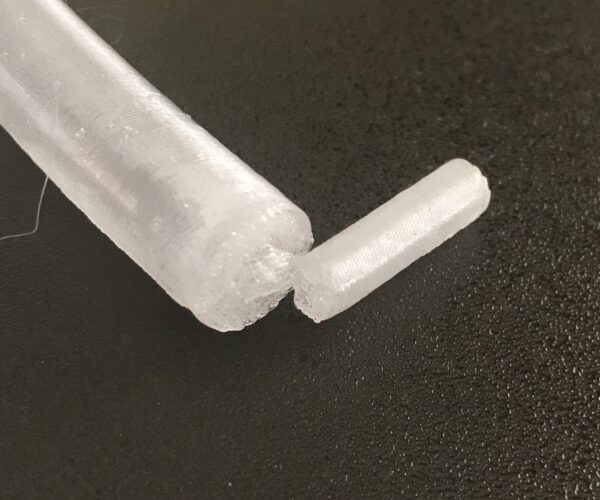

Unfortunately after assembling a few of the pieces a new problem showed itself. The transition from the greater to the smaller radius is wildly inconsistent in regards to stability. In about half the prints the smaller rod snaps off with minimal load. I will go back and try adding some infill, starting 1-2mm downwards from the transition. But this will generate an opaque end to the pieces that I wanted to avoid.

Would using a wider nozzle potentially make a difference? This should place more material there...

RE: still problems printing PETG/t-glase

The transition to the smaller diameter could be a number of things. Primarily layer adhesion, you are essentially joining 2 different peices one on top of another.

Try printing it horizontal instead of vertical, this will help strengthen the print and resist side load, and also increase your top number of layers. Without looking at your sliced profile, I am guessing you are essentially printing the smaller diameter on top of a top layer? Not sure if that makes sense or not.

In addition you may also need to adjust your temperatures, here is a neat test I ran across that I have used in the past. It is basically a scaled up version of your model.

Conclusion:

- First, check your temperatures and make sure they are correct.

- Next print orientation for optimal strength.

- Lastly adjust your perimeters for optimal strength.

Rich 3D

https://3dnewb.com

RE: still problems printing PETG/t-glase

The part in question (attaching the .3mf didn't work, if anybody wants to have a closer look I could email the file) is supposed to be a segment of a torus. The thinner bit sits perpendicular to the top level of the torus. 24 of them will form a circle and the excess part of the thinner rod will be the axis of a radial inset. If I find the time to virtually assemble the parts in F360 I will post a picture.

Printing the part horizontally wont work because that will significantly decrease transparency. I tried a single perimeter but that didn't give enough stability, although the transparency was better. I added thin wall support as a compromise to increase stability. Adding some infill at the top seems to improve things and loss of transparency is not an issue because this part is not visible in the assembled thing.

Temperaturewise I was using 240/95 initially but I will do some tests with higher temps (currently running a print at 250).

Maybe the whole project was a wee bit too ambitious as a first 3d printing exercise...

RE: still problems printing PETG/t-glase

Did you try printing 2 of them at the same time ? What I suspect is happening is that the print head is building layer upon layer at the same spot so the layers dont have time to properly cool before the next one is applied on top. This leads to exactly the type of issue you are seeing (I had the same issue with some very thin 3mm diameter tall spires). I added several to the build plate, that way the layer gets places on instance 1, it goes to instance 2 then 3 etc and by the time it gets back to instance 1 for the next layer its had time to cool.

Thats what altering the 'dont slow down unless layer time' setting is tweaking but I suspect its so quick at doing the layer anyway that no changes made there will be enough which is why I'd try printing 2 of them.

RE: still problems printing PETG/t-glase

Will try that in about 17 minutes when the hotter attempt is finished. Cooling time issues would also explain the little notch on the inside radius of the first 2 layers of the thinner bit. It looks like the top layers of the wider part are sagging inwards a bit.

And I discovered a new issue, see photo. Gets worse with higher temps. But transparency gets better with higher temps. This project starts to drive me mad...

RE: still problems printing PETG/t-glase

[...snip...]

attaching the .3mf didn't work, if anybody wants to have a closer look I could email the file

[...snip...]

This is an issue that has been complained about on this forum. The forum software doesn't accept files without pre-approved extensions. The .3mf file extension (which for this forum one would expect to be commonly uploaded) is not in that list of extensions. The forum software doesn't seem to do any checking of the file beyond looking at the name so you could rename the .3mf file as a .zip (try this on your computer, you will find that a .3mf file is actually a .zip file), but that could be confusing to the recipients. The most suggested method of uploading .3mf files here is to first zip it and upload the zip file. (Yes... I'm suggesting to zip up a zip file. Silly, I know, but that is how this forum software is configured...)

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: still problems printing PETG/t-glase

if the system wants to be zipped, I can oblige...

This is the breakpoint of the current iteration (250 degrees, 60% if). I will try to print 3 at the same time to allow for some more cooling.

RE: still problems printing PETG/t-glase

3 was the charm!

Thanks everybody for chipping in with all those ideas, learned quite a bit...