Slowing down purge speed at start of the print

Hello and thanks in advance for any assistance!

Im printing with ninjaflex and if I can get past the nozzle purge at the beginning I have great results. My issue is the extruder/print speed for the first strip laid down at the front edge of the bed causes the filament to squirm out between the drive gears. If I loosen the drive tension so it cant extrude during this strip then tighten it while the print head is moving to start the actual part I have no problem.

Can the speed of this purge strip be slowed down? If so how? I have looked at every setting I can find in slicer and in the mk3 with no luck.

Thanks!

Re: Slowing down purge speed at start of the print

I think the easiest is to tune/print speed. it should work.

I have a Prusa,therefore I research.

Re: Slowing down purge speed at start of the print

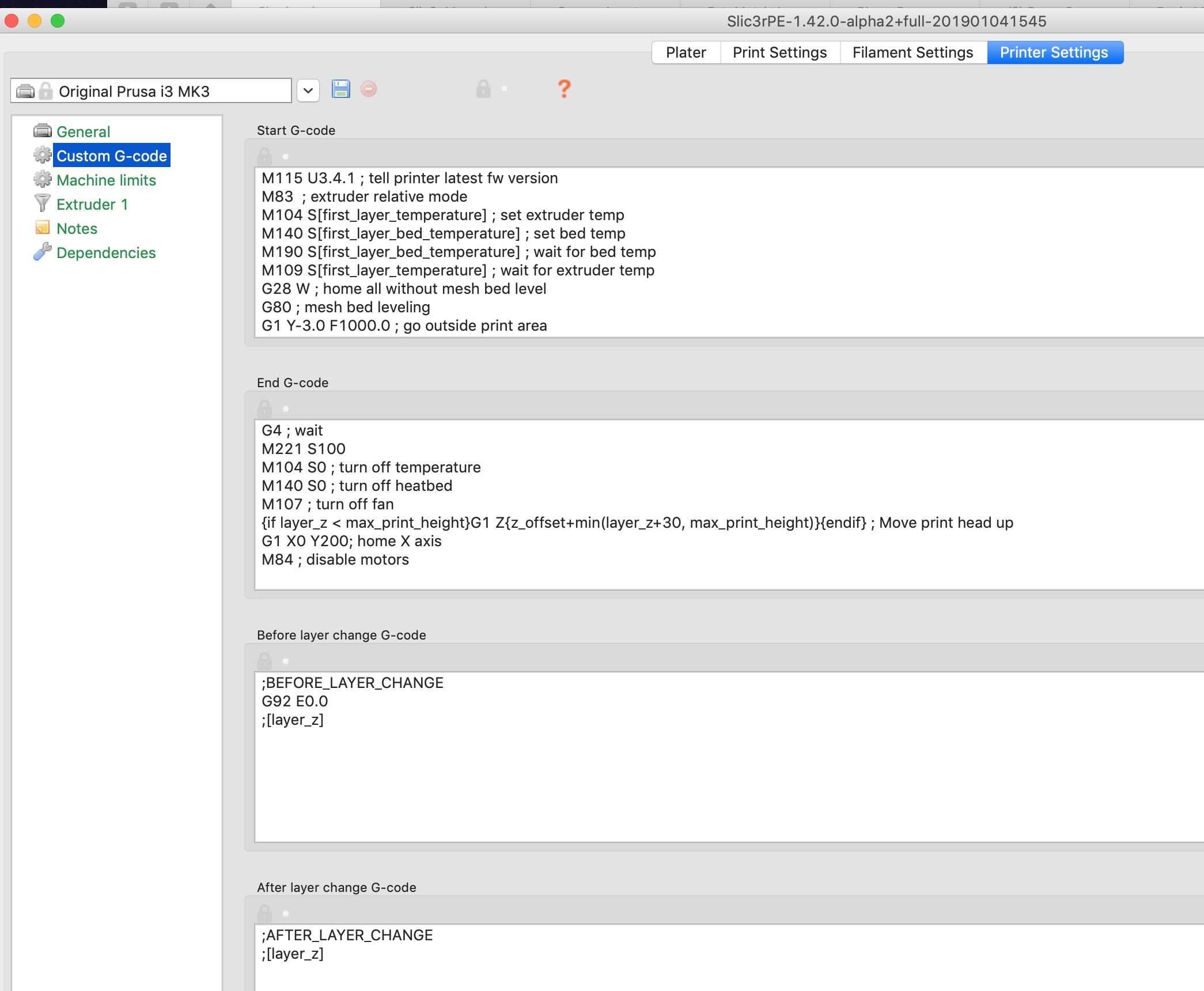

Why not just skip it altogether? Most slicers will let you customize the startup gcode. Just edit out the line(s) that print the purge strip. If you're using a skirt, it's a bit redundant anyhow (although still useful). If using Slic3r with the Prusa profile, one way would be to remove or comment these lines out:

[...] Can the speed of this purge strip be slowed down? If so how? I have looked at every setting I can find in slicer and in the mk3 with no luck.

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

There are a few other lines that are redundant that you could take out, or you could do something like set the E parameter to 0 to just move without extruding, etc. etc.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Slowing down purge speed at start of the print

Why not just skip it altogether? Most slicers will let you customize the startup gcode. Just edit out the line(s) that print the purge strip. If you're using a skirt, it's a bit redundant anyhow (although still useful). If using Slic3r with the Prusa profile, one way would be to remove or comment these lines out:

[...] Can the speed of this purge strip be slowed down? If so how? I have looked at every setting I can find in slicer and in the mk3 with no luck.

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

There are a few other lines that are redundant that you could take out, or you could do something like set the E parameter to 0 to just move without extruding, etc. etc.

Thanks for this answer. Im not a strong user of slicer yet. Where in settings will i find this g-code to edit?

Re: Slowing down purge speed at start of the print

Thanks. Ill take a look at that. I appreciate the responses .

Re: Slowing down purge speed at start of the print

Thanks removing the two lines from the G code worked perfectly. Eliminating the beginning purge also eliminated all the issues I was having with the filament squirming out the side of the extruder.

I did add one more loop to the skirt to ensure that the nozzle is purged, and no problems now with Ninjaflex I was able to increase print speed from 10mm/s to 12mm/s as well with a hot end temp of 245, and bed temp of 40. Extruder gears are adjusted so that after touching the filament I give both screws 1/2 turn.

Its working great now.

Thanks again!