Shifting layer on moon lamp

Hello everyone,

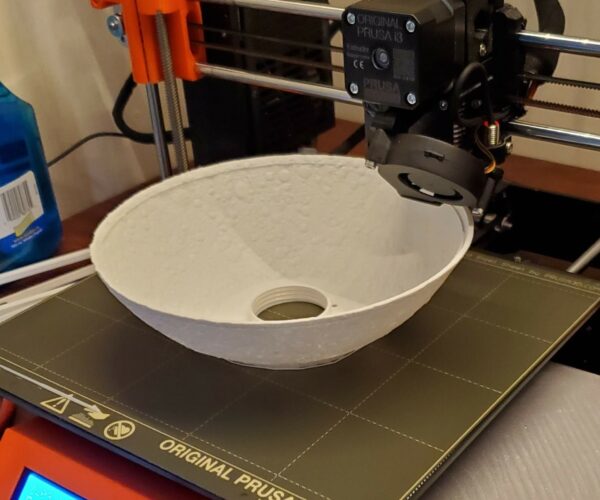

I'm having an issue printing this moon lamp. I've tried twice now and both times had the same error where it shifts and then continues printing.

Printer: MK3S

Filament: Amaz3d White PLA,

Temp: 201c / 60c

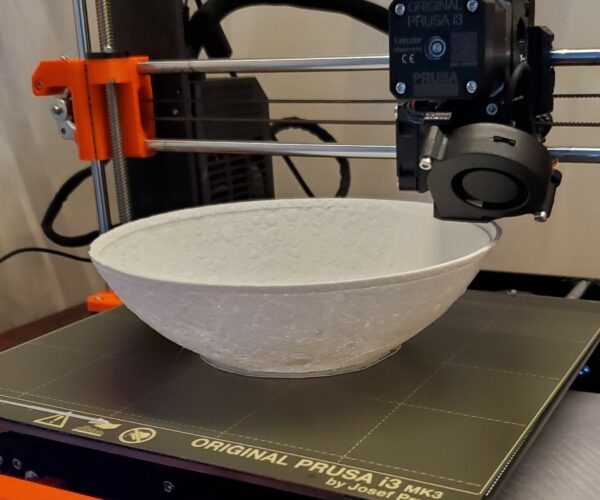

First attempt

Second attempt

I'm brand new to 3D printing. I've been printing smaller objects successfully for a few weeks now but this is by far the largest and longest print I've attempted and I feel like I've bitten off more than I can chew. Any advice on what to do to remedy this would be appreciated, thanks in advance.

RE: Shifting layer on moon lamp

Welcome in the Forum!

Check the smooth running of all axes from one stop to the other. The bearings may not tilt. Belt tension is also important, not too light, not too tight (between 250 and 290). What are the belt values in the self-test? Feed speed maybe too high?

Use the normal mode for larger objects (not stealth). Deactivate crash detection. Check the gear screw on the motorshaft. Use oil or lithium grease (Mogul LV 2-EP) for linear shaft lubrication (not for polymer/delrin bearings).

Try to increase Z-Hop or Fanspeed.

A happy new year!

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Shifting layer on moon lamp

Thank you for the advice.

I've lubricated all the smooth rods using the Prusa lubricant. They all seem to be running smoothly. My X was 292 and Y is 274. I've tightened the X belt and rerun the self-test. The new values are X 276 Y 274.

I've been running in normal mode for all prints but crash detection is on (or whatever default is, I have not modified it). I'll try disabling it? By gear screw on motor shaft do you mean what the orange arrows point to in this image?

RE: Shifting layer on moon lamp

[... snip ...]

By gear screw on motor shaft do you mean what the orange arrows point to in this image?

This is probably what he meant. Remember for this type of dual grub (set) screw the tightening order is very important. With both loose, tighten the grub screw against the flat of the shaft first. This will ensure that the grub screw is fully engaged against the shaft's flat face. Then tighten the other grub screw. Careful not to over tighten that you don't strip the allen socket of the grub screws...

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs