Rounded edges partially not round problem

Hi,

my print should be a sort of cuboid (from one side open box) with rounded edges, the lower part of it looking like this:

STL (Prusa Slicer before slicing):

After slicing (Prusa Slicer):

So still perfectly O.K. but:

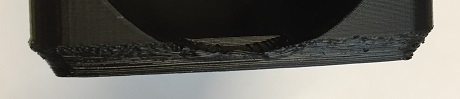

The print was looking like this:

Vertical edges were perfectly round as they should be but the horizontal ones close to the heat bed were simply cut under 45°

Any ideas? Thanks a ton

(Parameters in Prusa Slicer: Layer resolution: 0.10mm DETAIL, filament: Prusament ASA, printer: i3 MK3S, no support, infill: 15

Original STL from FreeCAD)

Best, Andreas

RE: Rounded edges partially not round problem

Your bottom rounded edges are in effect steep overhangs until they get further up the curve. That's why they look so rough when printed. When designing for 3d print using FFF its good practice to use either a single facet bevel at around 45 degrees or a combination of 45 degrees at the very bottom and then the smoother transition further up where the layers wont be producing the overhang to mitigate this limitation in the technology. You could also use support but in my experience it never leaves as nice and clean result as changing to a bevel does.

RE: Rounded edges partially not round problem

@neophyl

Thank you! I will try out immediatelly.

Best

Andreas

RE: Rounded edges partially not round problem

Also - have a closer look at the slice preview of that radiused edge with Detect Bridged Perimeters on. You should be able to see that many of the layers will be unsupported perimeters. So you end up with sloppy extrusions that adhere to layers in a random fashion. Once the perimeters have something below them, they then start stacking in a bit less random way and form something of a radius, but by that point the part is looking pretty ugly. As Neo said, reserve radiused edges for the top of a part, or plan to create custom supports.

RE: Rounded edges partially not round problem

Thank you guys! I used the combination suggested by neophyl (combination of 45 degrees at the very bottom and then the smoother transition further up) and everything is just looking great ! 🙂

RE: Rounded edges partially not round problem

Glad you are getting nice results 🙂

It takes practice getting used to the quirks of designing stuff for 3d printing. I'm slowly getting used to it and its becoming easier to ask myself questions like 'how am I going to orient this part for printing', 'if I do this in X number of parts that will be easier to print' etc. Things like holes that due to layers have a flat spot on the bottom/top you can add a little rooftop like angle so the layers stack better , especially if its not going to be seen.

RE: Rounded edges partially not round problem

I'm having the exact same problem. I really love the rounded edges on my project, but the base edges are unacceptable. I'll try changing the angles and/or change my design all together. Regardless of the outcome, at least I've learned something new and can manage my expectations moving forward. Many thanks for this post!