Pushing a polypropylene noodle

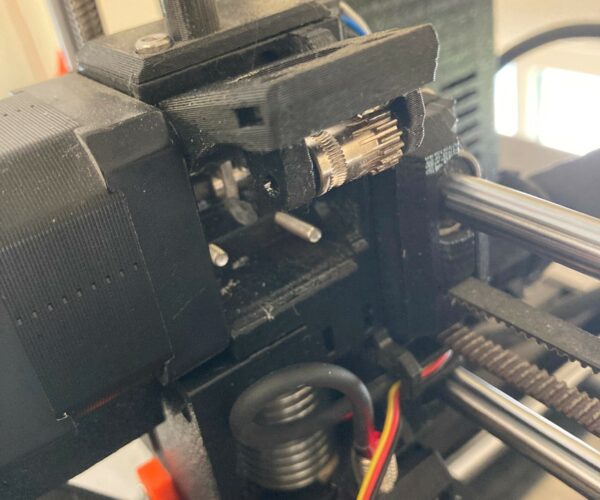

I am trying to print with polypropylene (Form Futura Centaur PP). Soon after my prints begin (5-20minutes) I start hearing a clicking sound and find that the filament has softened and crumpled above the PTFE tube and can no longer be fed into the extruder. Please see the pictures below. What confuses me is that the filament below this point is fine and not melted (also pictured). Does anyone have suggestions for this? I've tried printing in open air (climate controlled to 75degF), without an enclosure, thinking perhaps the already flexible filament was softening in the heat. This has not helped.

Heat Creep

What can happen when the temps are too high or the environment it too hot is the filament above the gears become plastic - and then all kinds of mischief can happen. If this is a flexible filament, it can also happen because the gears are overly tight for the parameters of the filament. For TPU, for instance, you need to back the filament feed tension way back - almost to the point of the screw leaves the nut on the tensioner. You may want to try backing off your bond-tech gear tensioner.