Prusament PCCF extrusion multiplier

Hi,

I printed Prusament PCCF with a 0.8mm nozzle for the first time and noticed some serious overextrusen. Printsettings were the PrusaSlicer defaults for this filament. The filament was brand new out of the bag, but I didn't dryed it before printing.

No other filament (not with 0.8 nozzle nor with any other) had such problems.

I adjusted the extrusion multiplier from the default 1.04 down to 0.8 and got pretty good results at 0.85.

The thing is, I never had to adjust the extrudion multiplier so much when using Prusament and the PrusaSlicer profiles. Could there be another problem, that caused this effect?

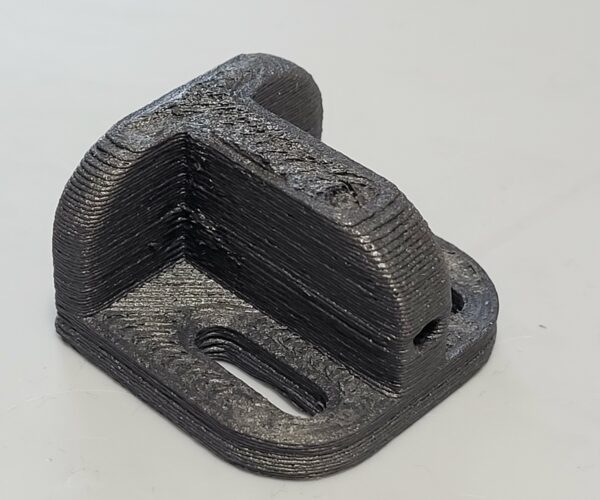

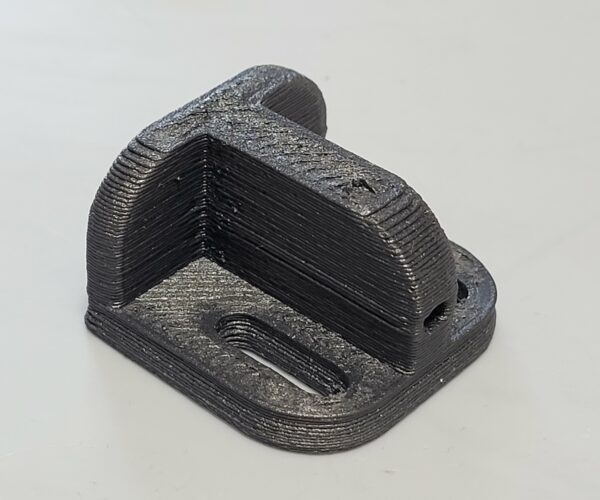

I've made some pictures, so you can see my printresults with different extrusion multiplier settings:

1.0:

0.95

0.9

0.85

0.8

RE: Prusament PCCF extrusion multiplier

I've not used PCCF myself, but looking at the spec sheet it prints at 285c, that's a really, really high temperature. I'm wondering what effect gravity is having on such a hot filament with such a wide nozzle.

Prusa recommends a hardened steel nozzle, is that what you're using? If not your temperature may be a little too high for brass.

Regards

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Prusament PCCF extrusion multiplier

Yes, I've used a hardened steel nozzle from E3D.

I think, gravity couldn't pull extra filament through the nozzle. Also, the print temperature of PC might be pretty high, but the molten PC shouldn't be thinner (less viscose) then other materials.

RE: Prusament PCCF extrusion multiplier

Like I said I haven't used such a large nozzle nor such a high temp. However, if you've ever noticed how your nozzle will drool while it's heating up that's the effect of gravity on molten plastic, the whole purpose of the purge line is to fill the gap left by the drool. I would expect that a larger nozzle would cause even more drool.

It could also be that you didn't get your settings correct for such a large nozzle and the solution you're employing is one way to adjust for the different flow rate required by such a nozzle. I'm assuming that since you're playing with the extrusion multiplier you first you made the necessary changes in the Extruder section of your printer profile.

Like I said, I've stuck with the standard 0.4 nozzle and haven't used PCCF so I'm just offering suggestions.

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Prusament PCCF extrusion multiplier

I’ve been using pccf with 0.6 nozzle and haven’t noticed this. That said with PLA I am able to make a Boolean cut of one shape from another and after printing the fit the two back together perfectly. This is not the case with Pccf and I have had to print the male and female parts with about 7% different to fit.

I wonder if your extrusion width is correct

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE:

Hello.

I recently printed my first PCCF parts with the 0.6mm profile (mk3s + revo) and i can confirm everything is way oversized. No doubt.

About 1mm to wide in general. Extrusion multipler must be turned down, the question is how much.

On a .6, things are considerably oversized but nowhere near to that extreme show above for a .8.

I'm starting a calibration cube endeavor.

RE: Prusament PCCF extrusion multiplier

And the results are here, for printing the Calibration cube on the MK3s @0.6 nozzle genuine profile - with a mounted revo, on firmware 3.11.0 (because revo).

Extrusion multiplier :

- 1.04 (original) => 10.53mm

- 1.0 => 10.49mm

- 0.85 => 10.25mm

- 0.78 => 10.14mm

I'm now running at 0.75 ! 😶and it's been much closer to expected dimensions. Top surfaces still closes nicely. Making a 28% saving too.

That is it for me, sufficient proof that either the default pccf profile by prusa is wacky and should be immensely turned down, or that revo makes a huge difference.

With that said, i want to blame the filament itself which measures inconsistently a lot. From 1.70mm to 1.80mm.

RE: Prusament PCCF extrusion multiplier

Did you measure the filament yourself? Or did you look at the curve provided by prusa?