Very interesting -compliments! Thank you for sharing 😀

[Mini+] [MK3S+BEAR]

RE: Topic

I would start a new thread. This topic is a little different than the question you have. Either way - filament from PET Bottle is tough to get to print because it often contains impurities.

Hi,

I know that this post is quite old, but I am trying to print with pure PET from recycled plastic bottles.

I did get quite good result with the following settings :

1) print temp 270°C

2) nozzle diam 0.6mm

I read somewhere that nozzle diameter must be bigger than regular petg due to a greater viscosity of PET.

I precise that I made my own filament from plastic bottles. I have a lot of pleasure to do this !

More here :

Look at the description and go to thingiverse link to see proper printing at 270°C

JP

--------------------

Chuck H

3D Printer Review Blog

Very interesting video, Freedom, thanks for posting this. I found your entry on Thingiverse as well.

I'm not sure if such a thing would be practical for me, but I'm always in favor of recycle/reuse and sometimes I'm appalled at the amount of plastic that we regularly throw out, including the boxes of 3d print scraps that I accumulate. Our SID's trash hauler told me when I phoned them that they do NOT want 3d print scraps put in their recycle containers, as they would just have to pull them out and put them in the regular trash, as whoever they send their plastic to does not want the 3d remnants.

I've seen the videos of the RecycleBot, but it looks very clumsy, time-consuming, and Rube-Goldberg-ish. (Looks like a lot of effort for a few meters of filament.) Plus I've heard horror stories from 3d print fans who have had bad luck using recycled (home brew or professional) filament. Your design looks more practical for a casual 3d print fan.

If you can get six meters or so of usable filament out of one water/soda bottle, that's a meaningful amount, and I commend your efforts and results! It looks like it prints cleanly using a more or less stock Prusa machine, although with a wider nozzle. That filament in your video looks almost like a spool of 'transparent blue' that I've used.

Now if there would only be a way to incorporate both concepts (RecycleBot, PullStruder) into a unit that could take both PET(g) 3d print scraps and soda/water bottles and make something like a PET/g-Blend that would work with the standard nozzle. In my mind I envision some kind of a heater that would melt scraps and such into a 'worm' (for lack of a better term) that could then be pulled through a PullStruder type of thing. Of course I have more than enough to keep me busy. 😉

printing with pure PET

I would start a new thread. This topic is a little different than the question you have. Either way - filament from PET Bottle is tough to get to print because it often contains impurities.

Well in fact it is not totally "off topic" !

I have got the same issues while printing my recycled PET filament. I don't think that it is due to impurities but rather that PET is not "obvious" to print.

I did have problem of clogging after the first layer. A bigger nozzle and a higher extrusion temp did the trick. (270°C and 0.6mm)

Have a look to this page : https://re-pet3d.com/product/re-pet3d-recycled-pet-filament-green/#tab-recommendations-for-printing-the-rpet-material

and select the tab 'recommendations for printing the rpet material" and also the "tip" tab.

Here is the content of this last one :

Here are a few tips and recommendations from a successful printer who is using our rPET material:

In my experience, “the best recipe” is to use an all-metal titanium heatbreak and print at 260°C without using a cooling fan or with just a small amount of blow. I recommend using a 0.6 mm nozzle, but with correct setting it is possible to use a 0.4 mm nozzle as well. I have not noticed any problems with slow printing, and I found that it was not even necessary to maintain a constant flow as otherwise recommended. But when printing large, complex, or complicated objects, I recommend putting a sponge with a few drops of oil on the string just to be sure. It does not affect the strength of the object and when using the sponge, it never happened to me, that the hot end would clog.

Most importantly, with rPET material it is practically impossible to print unless it is completely dry (even right out of the original packaging). For example, even a dried spool starts to foam during printing after only 2 hours of an air access. As a result, the retractions stop working because the evaporated moisture constantly pushes the material out of the nozzle. For this reason, it is crucial to always dry the material properly (usually I let it dry for about half a day in a fruit dryer set at 70°C) and then print directly after removing the material from the dryer, otherwise the quality will start to deteriorate again during printing.

and this :

We recommend printing our material at 250-260°C with a heated bed set to at least 80°C. For printing we advise to use a 0.6 mm nozzle, but with the correct setting and after drying the filament, it is possible to use a 0.4 mm nozzle without any problems. For successful printing, we also recommend the use of either a heatbreak with a teflon tube, which must be shortened to the same length as the end of the heatbreak, or an all-metal titanium heatbreak (ordinary all-metal iron heatbreak has a high tendency to stick and clog).

rPET material works better at higher speed. The same applies to the first layer, for which we recommend setting the speed to at least 70% of the speed compared to the other layers.

It is not advisable to leave the material even for a short time without extrusion and it is therefore necessary to ensure a constant flow, otherwise the extruder and nozzle will become clogged.

The back pressure of the bed and the nozzle at the first layer simultaneously limits the flow and the collection of material in the heating part of the extruder. This can be partially changed by moving the nozzle away from the bed, but this is not always sufficient. Therefore, it is advisable to manually replace the material after completing the first layer using the following script:...

RE: pullstruding

Now if there would only be a way to incorporate both concepts (RecycleBot, PullStruder) into a unit that could take both PET(g) 3d print scraps and soda/water bottles and make something like a PET/g-Blend that would work with the standard nozzle. In my mind I envision some kind of a heater that would melt scraps and such into a 'worm' (for lack of a better term) that could then be pulled through a PullStruder type of thing. Of course I have more than enough to keep me busy. 😉

I had the same idea, but it will not work.

The basic principle of the "pullstruder" is that you do not extrude the filament, you "pull" it. It is not melted but "shrinked" or "thermoformed". So it is crutial to have a consistent ribbon when you "pullstrude". If not you will never get a consistent filament when pulling on it.

It is also needed that the temperature for "pullstrusion" remains under the melteing temperature of the PET. 200°C is a good starting point.

I have tried to increase to 210°C it is easier to pull but sometimes the filament is not strong enough and breaks into the hotend. So finally 200°C is better although it needs a much stronger pull to get the filament !

RE: Answer

You appear to be talking about making your own where the original topic was on switching to PET after PLA. I was only pointing out that it does not entirely fit with the OP.

Either way, my answer still applies. I have found this type of filament to very difficult to print from roll to roll. I suspect it contains imputies. Every once and a while I get a roll that prints easily, but most of the the time, I get jams or poor adhesion. I just have not found it worth my time to make filament. I have a Filastruder that I monkeyed around with. It is neat to make your own color of PLA. I tried making some our of old PET bottles. That was more trouble than it was worth.

I would start a new thread. This topic is a little different than the question you have. Either way - filament from PET Bottle is tough to get to print because it often contains impurities.

Well in fact it is not totally "off topic" !

I have got the same issues while printing my recycled PET filament. I don't think that it is due to impurities but rather that PET is not "obvious" to print.

I did have problem of clogging after the first layer. A bigger nozzle and a higher extrusion temp did the trick. (270°C and 0.6mm)

Have a look to this page : https://re-pet3d.com/product/re-pet3d-recycled-pet-filament-green/#tab-recommendations-for-printing-the-rpet-material

and select the tab 'recommendations for printing the rpet material" and also the "tip" tab.

Here is the content of this last one :

Here are a few tips and recommendations from a successful printer who is using our rPET material:

In my experience, “the best recipe” is to use an all-metal titanium heatbreak and print at 260°C without using a cooling fan or with just a small amount of blow. I recommend using a 0.6 mm nozzle, but with correct setting it is possible to use a 0.4 mm nozzle as well. I have not noticed any problems with slow printing, and I found that it was not even necessary to maintain a constant flow as otherwise recommended. But when printing large, complex, or complicated objects, I recommend putting a sponge with a few drops of oil on the string just to be sure. It does not affect the strength of the object and when using the sponge, it never happened to me, that the hot end would clog.

Most importantly, with rPET material it is practically impossible to print unless it is completely dry (even right out of the original packaging). For example, even a dried spool starts to foam during printing after only 2 hours of an air access. As a result, the retractions stop working because the evaporated moisture constantly pushes the material out of the nozzle. For this reason, it is crucial to always dry the material properly (usually I let it dry for about half a day in a fruit dryer set at 70°C) and then print directly after removing the material from the dryer, otherwise the quality will start to deteriorate again during printing.

and this :

We recommend printing our material at 250-260°C with a heated bed set to at least 80°C. For printing we advise to use a 0.6 mm nozzle, but with the correct setting and after drying the filament, it is possible to use a 0.4 mm nozzle without any problems. For successful printing, we also recommend the use of either a heatbreak with a teflon tube, which must be shortened to the same length as the end of the heatbreak, or an all-metal titanium heatbreak (ordinary all-metal iron heatbreak has a high tendency to stick and clog).

rPET material works better at higher speed. The same applies to the first layer, for which we recommend setting the speed to at least 70% of the speed compared to the other layers.

It is not advisable to leave the material even for a short time without extrusion and it is therefore necessary to ensure a constant flow, otherwise the extruder and nozzle will become clogged.

The back pressure of the bed and the nozzle at the first layer simultaneously limits the flow and the collection of material in the heating part of the extruder. This can be partially changed by moving the nozzle away from the bed, but this is not always sufficient. Therefore, it is advisable to manually replace the material after completing the first layer using the following script:...

--------------------

Chuck H

3D Printer Review Blog

RE: pure PET printing

Either way, my answer still applies. I have found this type of filament to very difficult to print from roll to roll

yes, it's interesting to see that you have the same issues with commercial PET filament compared to my "homemade" one.

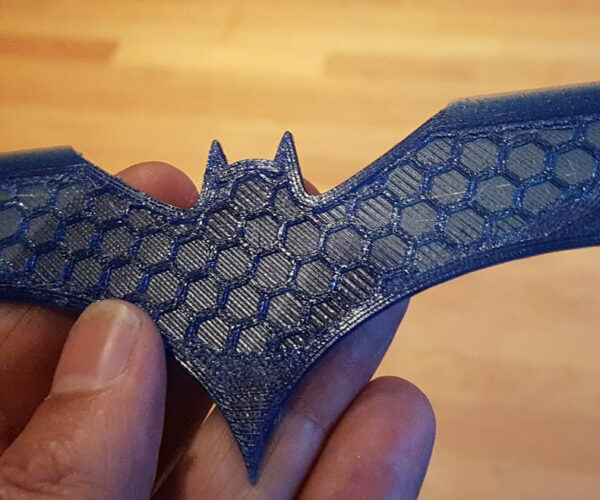

Here is how it prints now at 270° with .6mm nozzle.

Unfortunately not enough filament left to finish printing 🙁

I need to find a way to weld filaments to make a longer roll with more than one bottle !

rPET

Either way, my answer still applies. I have found this type of filament to very difficult to print from roll to roll

yes, it's interesting to see that you have the same issues with commercial PET filament compared to my "homemade" one.

Here is how it prints now at 270° with .6mm nozzle.

Unfortunately not enough filament left to finish printing 🙁

I need to find a way to weld filaments to make a longer roll with more than one bottle !

Clarification - it is a commercial rPET that I am having issues with.

--------------------

Chuck H

3D Printer Review Blog

RE: Problems printing pure PET after switching from PLA

Have You Been Having Problems Printing PET After Switching from PLA?

Have you recently switched from printing with PLA to PET and have been experiencing more problems than ever before? Well, this might not be a coincidence! Many 3D printer owners have found that when they switch from printing with PLA to PET, the filament tends to get stuck inside their nozzle and causes clogs. It may also cause the extruder motor to get overworked and burn out before its time.

What is PET?PET, or polyethylene terephthalate, is a type of plastic that's commonly used in food and beverage packaging. It's also frequently used in 3D printing filaments. PET is strong and durable, making it a good choice for printing functional parts. However, it can be difficult to print with because it has a tendency to warp. If you've been having problems printing PET since switching from PLA, here are some tips that might help.

Why Does it Seem Impossible to Print PET at Home?PLA and PET are both thermoplastic polymers, but they have different properties that make them difficult to print with on a home 3D printer. PLA is easier to print with because it has a lower melting point and is less likely to warp. PET, on the other hand, has a higher melting point and is more likely to warp. This means that you need a printer that can reach high temperatures in order to print with PET.

What are the Possible Reasons for this Issue?If you've been having problems printing PET after switching from PLA, it could be due to a number of reasons. The first is that the temperature of your extruder may be too low. PET requires a higher temperature to melt properly, so if your extruder is set too low, you'll likely have issues. Another possibility is that your bed temperature is too low. Again, because PET requires a higher temperature to melt properly, a lower bed temperature can cause problems.

How Did I Finally Overcome this Problem with My Printer?If you've been having problems printing PET after switching from PLA, there are a few things you can try to overcome this issue. First, make sure that your printer is properly calibrated. If it's not, you may need to adjust your settings. Second, check the quality of your filament. If it's not up to par, it could be causing your prints to fail. Finally, make sure that you're using the correct settings for your printer and material.

Summary - Overcoming Hard-to-Print Filaments IssuesOne of the great things about 3D printing is that there are so many different types of filaments available. However, this can also be a problem when you try to switch from one type to another. For example, many people have found that they have problems printing pure PET after switching from PLA. In this blog post, we'll explore some of the reasons why this might be happening and offer some solutions for overcoming hard-to-print filament issues.

RE: Problems printing pure PET after switching from PLA

@cwbullet would you mind telling me which 3d printer you use for the PET? I'm brand new to 3d printing and i'm in the research phase of finding the right printer for me: one that has high enough temperatures for PET, but isnt too expensive and works as a good beginner printer