Problems not known

Hi

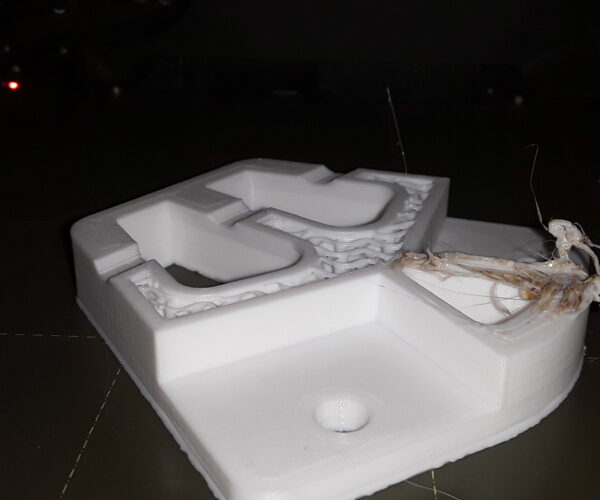

Again I'm here, having some problems I don't know how to address to.

This is my 4th attempt, and obviously somethings wrong...

Before the tries, I had to clean the complete hotend after PA filament made everythings nasty. Now, after reassembly this happens...

Also: when starting a print job now, the printer always starts by telling me I should change the filament... Why??

Thanks a lot, guys.

RE: Problems not known

First layer calibration Z-offset is too high.

Mk3S+,SL1S

RE: Problems not known

My z-Adjust would have been at - 1.475mm before.

I lowered it down to 1.625, until the extruder started jumping... and lifted back to -1.500mm.l (until jumping stopped).

Hope that helps (unless it's reasonably little difference in reach..? )

Thanks for your answer.

Why does my printer stops and prompts for Filament Change after z-Calibration/ before it starts to print the job? It does it since I updated firmware (V. 3.10.0)

Thanks again

RE: Problems not known

Could be something in your startup gcode or the filament sensor is out of whack.

Would help if you saved the project from PrusaSlicer as a 3mf file, zipped it, and uploaded it here. This way we could see all your settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Problems not known

(after taken the Photo I raised the nozzle temp to plus 2 degrees)

The filament I use here is

FIBERLOGY PCTG

RE: Problems not known

For one, in the 3mf project you have a color change at 0 mm ☹️ That's why you're prompted to switch filament. Just right click at the very bottom of the vertical slide in the preview and delete it.

Layer shift...

Can be many things. For one, the temperatures you've chosen seem ultrahigh for PETG but then again I've never used this particular brand.

I would also add a skirt to make sure anything stuck on the nozzle gets removed before the actual model is printed. And for PETG make sure the nozzle and heater block are as clean as possible.

And my check list for common reasons for layer shifts:

Pulley screws on X motor not properly tightened. One has to be tightened against the flat side of the motor shaft!

Belt not correctly tightened. Use this tension meter to get it right: https://www.prusaprinters.org/prints/46639 X carriage over-squeezed. Loosen the back plate on the X carriage axis.

Nozzle hit an obstacle. Some patterns such as grid have lines that cross within one layer. This can lead to little pile-ups at the intersection points, in particular if you have slight overextrusion, which in turn can lead to the nozzle catching at those pile-ups. See https://help.prusa3d.com/en/article/infill-patterns_177130/

Zip ties on the wire bundle on the back of the extruder not properly positioned, so they or the cables hit the model.

And lastly, make sure the steel sheet is super clean. Lots of hot water and dish washing soap.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Thank alot for your complete answer.

Will recheck!

Last glob/ooze built up at Z=41.9 (before Z=14.9, even before at Z=2.5,... first at Z=0.7)

Hope to get there eventually by retuning and checking list, thanks.

And thanks for that filament change entry...

Ps: Heatsink and all around it was super clean, even serviced it incl. servicing PTFE-Hose. No straps or anything else hanging down... What causes the ooze-buildup no idea. Thought maybe a faulty heatsink.

RE: Problems not known

in my experience with petg you get blobbing/boogers when the extrusion multiplier is too much. I find that with petg, I usually have to do less than one, say .94-.95. you can test this out at the printer by just tuning the flow during print. the default if you go and tune during print is .95. This is a good starting value if you're seeing blobbing.

RE: Problems not known

Thanks.

I went from .95 at the beginning down to .94...

Think of getting even lower...

RE:

OK, thanks all.

I now will put this thread to :solved: soon

...

All seem working now - the reasons of the hickups were:

1) the multipler was put to high

2) the Z-displacement happened obviously through the built up of oozes/globs from time to time... And the printer head displaced after skating over that ones.

At the end I want to address that I took a default filament for Fiberlogy PETG... and tried to adopt it to my needs, as I use a slightly different material called Fiberlogy PCTG.

Not aware if there're settings out there my Prusaslicer runs WITHOUT Internet connection (as my whole pc isn't connected) -

and I really wanna emphasise Prusa again, to put Filament Default Settings online again as collections to download.

I'd appreciate very much

RE: Problems not known

Hi again - found the problem!

I have leakage on my nozzle. So, I reassembled the nozzle improperly after cleaning!!!

OK, thanks all.

I now will put this thread to :solved: soon

...

All seem working now - the reasons of the hickups were:

1) the multipler was put to high

2) the Z-displacement happened obviously through the built up of oozes/globs from time to time... And the printer head displaced after skating over that ones.

At the end I want to address that I took a default filament for Fiberlogy PETG... and tried to adopt it to my needs, as I use a slightly different material called Fiberlogy PCTG.

Not aware if there're settings out there my Prusaslicer runs WITHOUT Internet connection (as my whole pc isn't connected) -

and I really wanna emphasise Prusa again, to put Filament Default Settings online again as collections to download.

I'd appreciate very much

RE: Problems not known

Have you found the Prusa Knowledge base article on nozzle replacemet?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Problems not known

Yes I made this mistake before after changing from a brass to a steel nozzle.

Hi again - found the problem!

I have leakage on my nozzle. So, I reassembled the nozzle improperly after cleaning!!!

OK, thanks all.

I now will put this thread to :solved: soon

...

All seem working now - the reasons of the hickups were:

1) the multipler was put to high

2) the Z-displacement happened obviously through the built up of oozes/globs from time to time... And the printer head displaced after skating over that ones.

At the end I want to address that I took a default filament for Fiberlogy PETG... and tried to adopt it to my needs, as I use a slightly different material called Fiberlogy PCTG.

Not aware if there're settings out there my Prusaslicer runs WITHOUT Internet connection (as my whole pc isn't connected) -

and I really wanna emphasise Prusa again, to put Filament Default Settings online again as collections to download.

I'd appreciate very much