Prints Failing (i3 mk3+)

I am a complete newbie to 3d printing. I have a Prusa i3 mk3 that is only a couple months old. I have barely used it so far.

Everything has been reliable until today. I don't know what is wrong, if there is a malfunction or if I am doing something wrong.

It started like this: Prints would begin okay, first layer adheres to the sheet fine. Then after 10-45min of printing the upper layer(s) will fall off a lower layer, sometimes close to the build plate but not always.

Once this happens the area around my printer looks like someone threw spaghetti at it with printed filament haphazardly everywhere.

I have tried:

1. Cleaning the build sheet with the hotest water my plumbing gives me + dawn dish soap, scrubbed with a sponge. Several minutes of letting hot water rinse it, I dry it with paper towels. The entire time I am handling the sheet (start to finish) I am wearing fresh latex gloves so I know for a fact this is not from my greasy hands touching this.

2. Applying glue stick (the one supplied with the printer from Prusa) to the build sheet. I run the glue stick over it front to back and then side to side. No improvement, which I figured would happen since the base layer was adhering fine.

3. Redoing the various calibration settings inside the printer's menu options.

4. Increasing the temperature settings for the print by 10 degrees (for both the nozzle and the hot bed).

5. Scrubbing the outside of the nozzle with a brass wire brush in case there was any filament stuck to it.

As my troubleshooting went on the problem worsened. Print failures were occurring sooner and then the prints stopped adhering to the bed.

I am confident that the build sheet is clean. I have taken precautions to not even handle it with my bare hands/skin, and honestly I dont think it would get any cleaner if I put it in my darn ultrasonic cleaner.

I don't know whats wrong.

RE: Prints Failing (i3 mk3+)

Then after 10-45min of printing the upper layer(s) will fall off a lower layer, sometimes close to the build plate but not always.

I'm trying to understand this… So the newly put down layer is not properly connected to the layer below? But what has been printed is still attached to the sheet?

In that case all the things you mentioned won't help as they only affect the first layer and adhesion to the sheet.

Without pictures, my wild guess is that you may have underextrusion issues due to a (partially) clogged nozzle. If you could post some pictures, it may help to better diagnose what's going on.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

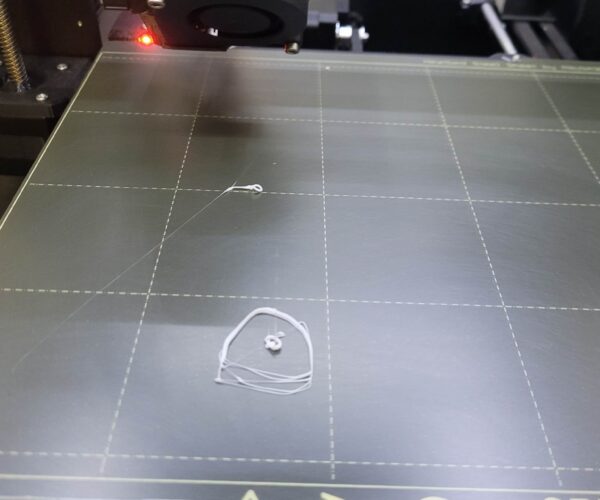

The problem started off with the first ~10-20% of my print working successfully, and then anything it tries to print beyond that doesn't adhere to the existing print and it starts shooting filament strings/debris all over the workbench.

But in trying to troubleshoot the problem, it has gotten worse until now even the first initial layer does not work.

I think you're correct, I have a clog. Somewhere. But I don't know where, what caused it, or how to fix it.

I tried (in order attempted):

1. The "cold" unclogging process where you turn off filament autoload, turn up the nozzle temperature setting, and then push filament through continuously while it cools down to 85 degrees. Then pull the filament out after it cooled. I have spent over an hour doing this with no success.

2. I opened the "door" on the right side of the head assembly and no debris, jam, clog etc is visible. The clog, which must be partial in nature, is below this point somewhere.

3. I read a comment somewhere where someone suggested pushing (with autoload off) a max 1-mm diameter single conductor wire into the head assembly and push it down/through. I cannot push it all the way through but this did dislodge some burnt looking material.

4. Set the temperature on max and pushed filament through continuously until the machine tripped the max temperature alert and shut itself down.

The machine will successfully feed filament through when trying to print, but its not working correctly.

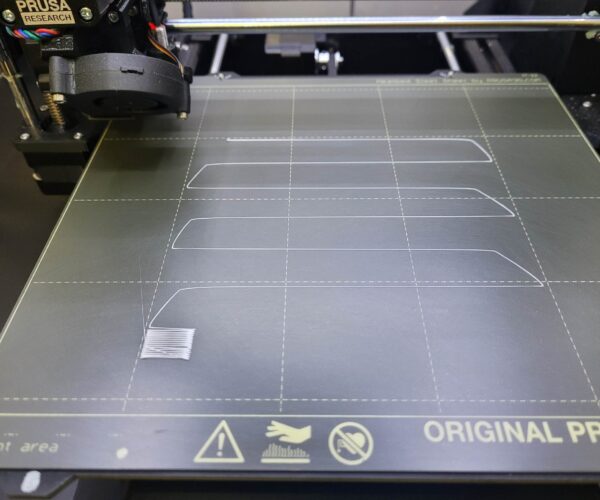

Pictures (first was from the built in calibration procedures and you can see how its not laying the first layer correctly), other pictures show print attempts failing at first layer. Problem must be getting worse.

What causes clogs? Is this something I did incorrectly or is this something that just happens occasionally?

RE: Prints Failing (i3 mk3+)

Also the 3mf file

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

Its an stl, but I can't share it because its proprietary & not mine.

However, the problem is the same regardless what stl I attempt to print, i.e. the prusa test print that came on the original SD card.

Also the 3mf file

RE:

@sgath92 when you import it into prusa slicer go file save project as then that will save it as a 3mf file wich contains all your print settings

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

Oh, I see. Okay, how does one upload a 3mf file to this forum? I tried to attach it and the forum software said it can't use it due to security settings.

Anything I send to the printer fails in the same way, including if I try to just use the OEM default gcodes on the factory original SD card.

@sgath92 when you import it into prusa slicer go file save project as then that will save it as a 3mf file wich contains all your print settings

RE: Prints Failing (i3 mk3+)

Zip it

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

Put it into a zip file also images of printer and all angles of extruder and hotend many thanks

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

Put it into a zip file also images of printer and all angles of extruder and hotend many thanks

Here it is.

RE: Prints Failing (i3 mk3+)

Your problem is first layer you either need to go way lower or way higher try both untill you get a nice result then post the better result try go up first

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE:

actully looking at it again you probally need to go way lower refer to https://help.prusa3d.com/article/first-layer-calibration-i3_112364

also acording to your file you are using a 0.10 mm nozzle i would recomed printing in .4 mm nozzle like the one that came with printer your choice though

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

I haven't changed the nozzle from what it shipped with from Prusa, so it should be a .4mm.

I will try the link's instructions tomorrow when I wake up (its nearly 3am my time).

actully looking at it again you probally need to go way lower refer to https://help.prusa3d.com/article/first-layer-calibration-i3_112364

also acording to your file you are using a 0.10 mm nozzle i would recomed printing in .4 mm nozzle like the one that came with printer your choice though

RE: Prints Failing (i3 mk3+)

also acording to your file you are using a 0.10 mm nozzle i would recomed printing in .4 mm nozzle like the one that came with printer your choice though

I don't see that. When I open the 3mf it shows me a 0.4mm nozzle config. It it set to 0.1mm layer height though. That's not a problem but feels excessive for this model with no vertical details. I'd use 0.2 mm (and 15% infill, 3 perimeters) and cut the time to print it down in half. Otherwise settings look fine to me.

From the first layer photo I don't see a clogging issue but your live z is way too high. You need to go lower. I use this calibrations strip to get it perfect: https://www.prusaprinters.org/prints/105404

As far as the spaghetti is concerned, a couple of thoughts. The first one may be farfetched, but it has happened to me (alas, more than once). I tried to print PETG but accidentally sliced it with PLA settings. It usually prints the first layers fine then chaos ensues…

The second thought: Try printing a temp tower to make sure your temperature is okay. E.g., https://www.prusaprinters.org/prints/39810

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Prints Failing (i3 mk3+)

I'm sure when I opened file I slice it said make modified and the it said 10 mm nozzle I may be wrong and looking at wrong thing I will check tonight anyway yes like I said first layer is way to high

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Prints Failing (i3 mk3+)

Okay everyone an update.

I did the first layer configuration and it seems as through somehow the unit had lost its first layer configuration setting completely and was set to "zero". I do not know how this happened because I know for a fact I have not adjusted this setting (either by going into it or by adjusting live Z during a print).

This is a Prusa assembled unit not a kit, so per the instruction manual there was no reason for me to make any adjustments for this (as the book says that's just for kit builders).

I admit I do not fully know what I am doing, but I adjusted it down to -.1100 and now it is printing, but resolution is off so it is probably not set right. I basically kept redoing the first layer configuration until the zig-zag it was laying down adhered to the board in such a way that the "turns" in the pattern were sticking at the proper 90 degrees and the solid rectangle at the end of the pattern came off as one part instead of pulling off like hair-strands/untangling (if that makes sense).

The print looks like it still has some areas which are not fully solid (i.e. strand 1 adjacent to strand 2, on the same Z axis, may have gaps- but intermittently so). I also had ironing on and with two identical parts it ironed one successfully but not the other.

I am printing PLA bought directly from Prusa, though I have run two rolls of Amazon (various brands) PLA and one Amazon (generic brand) PETG (to make the enclosure parts). As you can see in the zip file, I made the MMU2 compatible lack table v2 enclosure because I figure if I can learn enough to know what I am doing with the printer -in the future- I want to do & learn the MMU2 kit, I just don't think I am ready to make that jump yet (which I guess this thread shows).

Anyhow, I have not made any prints sliced for PLA with PETG, but I did do a few of my first prints the other way around (sliced for PETG but ran with PLA). But that actually worked fine (no problems with the prints) and the printer ran find doing other stuff for a few weeks with no incidents.

So either this is a computer bug, causing it to loose its first layer calibration (setting it at a value of zero), or, if I am understanding the manual correctly, the PINDA has physically changed position to make the calibration bad. But I do not think this last one is plausible here, as from what I am reading the first layer calibrations are almost never set (by Prusa OR kit builders) to a value of "0.000"