Printing with PETG

Hi,

I've been printing quite a bit with PLA without problems and have recently switched to PETG. I'm using the SUNLU 1.75 filament, slic3r with pet filament settings on the "detail" profile mk3 profile.

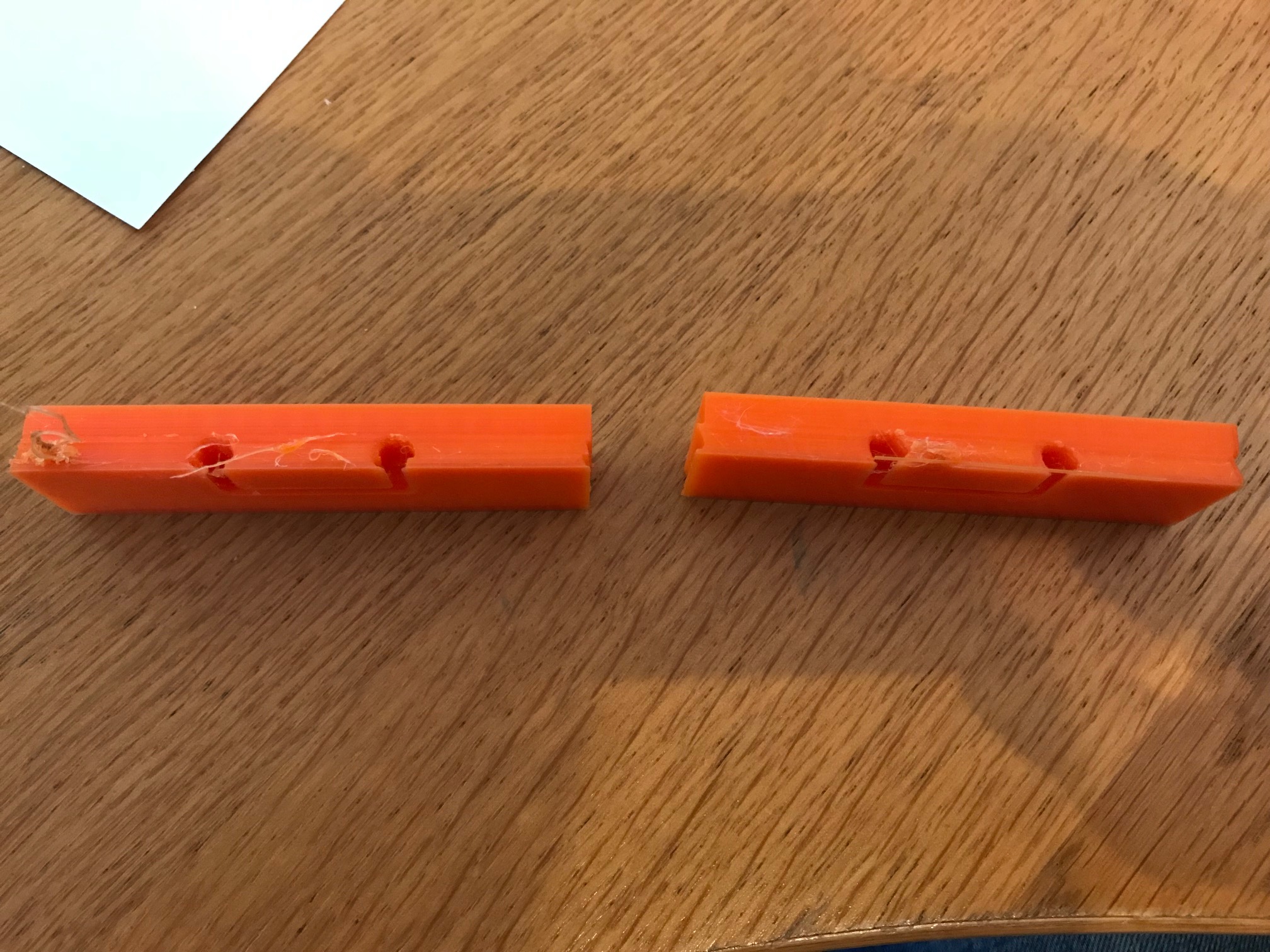

I've got a shape I've tried printing - a rectangular block with two almost complete holes. The print on the left was printed @ 220 degrees and the right 250 degrees. It was printed so that as you look at the object, the face on the bottom was on the bottom of the sheet.

Should I be expecting better results than this? any ideas on how to improve the printing? it's currently 5 degrees in my garage where I'm printing.

Thanks

Andy

Re: Printing with PETG

It probably depends on the temperature in the garage. But does your printer really print at that temperature. It shouldn't.

Bear MK3 with Bondtech extruder

Re: Printing with PETG

I'll post you my SUNLU PETG settings when I finish work this afternoon, But, I could not get perfect prints at 0.15 Detail settings. just Fast 0.2 settings.

I found SUNLU PETG was a little too oozy and stringy at temperatures where bridging was successful with Detail settings (0.15mm layer height).

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

Re: Printing with PETG

Sorry, bit busy so have only managed to get in front of the computer today.

Just copy the following into a text file and rename it to config.ini then import to slicer. This is for SUNLU PETG which I print at 230 Deg C, I fins any higher it is just too stringy and oozy.

Note:, I use modified firmware which carries out a 7x7 mesh bed leveling so in the custon G-code for printer settings there is a line G80 N7.

If this causes you an issue, just remove the N7 part. Also the head moves to just above the bed and preheats the PINDA before carrying out mesh bed levelling.

# generated by Slic3r Prusa Edition 1.41.2+win64 on 2019-02-10 at 07:34:40

avoid_crossing_perimeters = 0

bed_shape = 0x0,250x0,250x210,0x210

bed_temperature = 85

before_layer_gcode = ;BEFORE_LAYER_CHANGE\nG92 E0.0\n;[layer_z]\n\n

between_objects_gcode =

bottom_solid_layers = 5

bridge_acceleration = 1000

bridge_angle = 0

bridge_fan_speed = 100

bridge_flow_ratio = 0.8

bridge_speed = 50

brim_width = 0

clip_multipart_objects = 1

compatible_printers_condition_cummulative = "printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK3.*/ and nozzle_diameter[0]==0.4";"! (printer_notes=~/.*PRINTER_VENDOR_PRUSA3D.*/ and printer_notes=~/.*PRINTER_MODEL_MK3.*/ and single_extruder_multi_material)"

complete_objects = 0

cooling = 1

cooling_tube_length = 5

cooling_tube_retraction = 91.5

default_acceleration = 1000

default_filament_profile = "Prusa PLA"

default_print_profile = 0.15mm OPTIMAL MK3

deretract_speed = 0

disable_fan_first_layers = 2

dont_support_bridges = 1

duplicate_distance = 6

elefant_foot_compensation = 0

end_filament_gcode = "; Filament-specific end gcode"

end_gcode = G1 E-1.2 F2100; bobstro Anti stringing retract and moves to avoid stringing\nG4 ; wait\nM221 S100\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\n{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+30, max_print_height)}{endif} ; Move print head up\nG1 X0 Y200; home X axis\nM84 ; disable motors

ensure_vertical_shell_thickness = 1

external_fill_pattern = rectilinear

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 35

external_perimeters_first = 0

extra_loading_move = -2

extra_perimeters = 0

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_colour = #FFFF00

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0.45

fan_always_on = 1

fan_below_layer_time = 20

filament_colour = #FF8000

filament_cooling_final_speed = 3.4

filament_cooling_initial_speed = 2.2

filament_cooling_moves = 4

filament_cost = 27.82

filament_density = 1.24

filament_diameter = 1.75

filament_load_time = 0

filament_loading_speed = 28

filament_loading_speed_start = 3

filament_max_volumetric_speed = 8

filament_minimal_purge_on_wipe_tower = 15

filament_notes = "List of manufacturers tested with standart PET print settings for MK2:\n\nE3D Edge\nFillamentum CPE GH100\nPlasty Mladeč PETG"

filament_ramming_parameters = "120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6"

filament_settings_id = "SUNLU PETG 230"

filament_soluble = 0

filament_toolchange_delay = 0

filament_type = PET

filament_unload_time = 0

filament_unloading_speed = 90

filament_unloading_speed_start = 100

fill_angle = 45

fill_density = 20%

fill_pattern = gyroid

first_layer_acceleration = 1000

first_layer_bed_temperature = 85

first_layer_extrusion_width = 0.4

first_layer_height = 0.2

first_layer_speed = 20

first_layer_temperature = 230

gap_fill_speed = 35

gcode_comments = 0

gcode_flavor = marlin

host_type = octoprint

infill_acceleration = 1250

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 200

interface_shells = 0

layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]\n;{if layer_z==0.6}M104 S215{endif}\n;{if layer_z==8.2}M104 S220{endif}\n;{if layer_z==16.2}M104 S225{endif}\n;{if layer_z==24.2}M104 S230{endif}\n;{if layer_z==32.2}M104 S235{endif}\n

layer_height = 0.2

machine_max_acceleration_e = 5000,5000

machine_max_acceleration_extruding = 1250,1250

machine_max_acceleration_retracting = 1250,1250

machine_max_acceleration_x = 1000,960

machine_max_acceleration_y = 1000,960

machine_max_acceleration_z = 1000,1000

machine_max_feedrate_e = 120,120

machine_max_feedrate_x = 200,172

machine_max_feedrate_y = 200,172

machine_max_feedrate_z = 12,12

machine_max_jerk_e = 1.5,1.5

machine_max_jerk_x = 8,8

machine_max_jerk_y = 8,8

machine_max_jerk_z = 0.4,0.4

machine_min_extruding_rate = 0,0

machine_min_travel_rate = 0,0

max_fan_speed = 50

max_layer_height = 0.25

max_print_height = 210

max_print_speed = 200

max_volumetric_extrusion_rate_slope_negative = 0

max_volumetric_extrusion_rate_slope_positive = 0

max_volumetric_speed = 0

min_fan_speed = 30

min_layer_height = 0.07

min_print_speed = 15

min_skirt_length = 4

notes =

nozzle_diameter = 0.4

only_retract_when_crossing_perimeters = 0

ooze_prevention = 0

output_filename_format = {input_filename_base}_{layer_height}mm_{filament_type[0]}_{printer_model}.gcode

overhangs = 1

parking_pos_retraction = 92

perimeter_acceleration = 800

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 45

perimeters = 2

post_process =

print_host =

print_settings_id = 0.20mm FAST SUNLU PETG

printer_model = MK3

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK3\n

printer_settings_id = SUNLU 7x7 PETG

printer_variant = 0.4

printer_vendor =

printhost_apikey =

printhost_cafile =

raft_layers = 0

remaining_times = 1

resolution = 0

retract_before_travel = 1

retract_before_wipe = 0%

retract_layer_change = 1

retract_length = 1.4

retract_length_toolchange = 4

retract_lift = 0.6

retract_lift_above = 0

retract_lift_below = 209

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 45

seam_position = nearest

serial_port =

serial_speed = 250000

silent_mode = 1

single_extruder_multi_material = 0

single_extruder_multi_material_priming = 0

skirt_distance = 2

skirt_height = 3

skirts = 1

slowdown_below_layer_time = 20

small_perimeter_speed = 25

solid_infill_below_area = 0

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 200

spiral_vase = 0

standby_temperature_delta = -5

start_filament_gcode = "M900 K{if printer_notes=~/.*PRINTER_HAS_BOWDEN.*/}200{else}45{endif}; Filament gcode"

start_gcode = M115 U3.3.1 ; tell printer latest fw version\nM83 ; extruder relative mode\nG28 W ; MUST FIRST home all without mesh bed level or else risk nozzle crash!\nG0 X70 Y70 Z0.5 F1000; PINDA warms faster near bed \nM140 S[first_layer_bed_temperature] ; set bed temp\nM104 S150 ; preheat extruder to no ooze temp to help warm PINDA\nM109 S150 ; wait for extruder temp\nM190 S[first_layer_bed_temperature] ; wait for bed temp\nM860 S35 ; wait for PINDA temp. For most stable PINDA temp during mesh, set temp here 1-2 deg below your actual PINDA temp at end of mesh cal.\nM104 S100 ; drop extruder to lower temp to minimize PINDA temp rise during mesh\nG80 N7 ; mesh bed leveling with extra points\nG1 Y-3.0 F1000.0 ; go outside print area\nG92 E0.0\nG1 Z3 ; raise head safely clear of bed before heating extruder\nM104 S[first_layer_temperature] ; we heat extruder AFTER mesh to minimize ooze\nM109 S[first_layer_temperature] ; wait for extruder temp\nG1 Z0.5 ; move slightly above bed for easy clean intro line\nG1 X60.0 E9.0 F1000.0 ; intro line\nG1 X100.0 E12.5 F1000.0 ; intro line\nG1 E-0.8 F2100; bobstro Anti stringing retract and moves to avoid stringing\nG1 X99.0 E0 F1000.0 ; -1mm intro line @ 0.00\nG1 X110.0 E0 F1000.0 ; +10mm intro line @ 0.00\nG1 Z0 ;lower head back to normal Z after intro line\nG92 E0.0\nM221 S{if layer_height==0.05}100{else}95{endif}

support_material = 0

support_material_angle = 0

support_material_auto = 1

support_material_buildplate_only = 0

support_material_contact_distance = 0.1

support_material_enforce_layers = 0

support_material_extruder = 0

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 0

support_material_interface_layers = 2

support_material_interface_spacing = 0.2

support_material_interface_speed = 100%

support_material_pattern = rectilinear

support_material_spacing = 2

support_material_speed = 50

support_material_synchronize_layers = 0

support_material_threshold = 55

support_material_with_sheath = 0

support_material_xy_spacing = 50%

temperature = 230

thin_walls = 0

threads = 6

toolchange_gcode =

top_infill_extrusion_width = 0.4

top_solid_infill_speed = 50

top_solid_layers = 5

travel_speed = 200

use_firmware_retraction = 0

use_relative_e_distances = 1

use_volumetric_e = 0

variable_layer_height = 1

wipe = 1

wipe_into_infill = 0

wipe_into_objects = 0

wipe_tower = 1

wipe_tower_bridging = 10

wipe_tower_rotation_angle = 0

wipe_tower_width = 60

wipe_tower_x = 170

wipe_tower_y = 125

wiping_volumes_extruders = 70,70

wiping_volumes_matrix = 0

xy_size_compensation = 0

z_offset = 0.025

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.