Printing With NylonX

Hi , I´m printing with NylonX (Nylon + Carbon fiber), and i cannot get the piece well glued to the heatbed. I tried everything. I slowed the speed values, and it got better, just a bit. I print with brim, the brim does not warp, the piece just slides a bit .

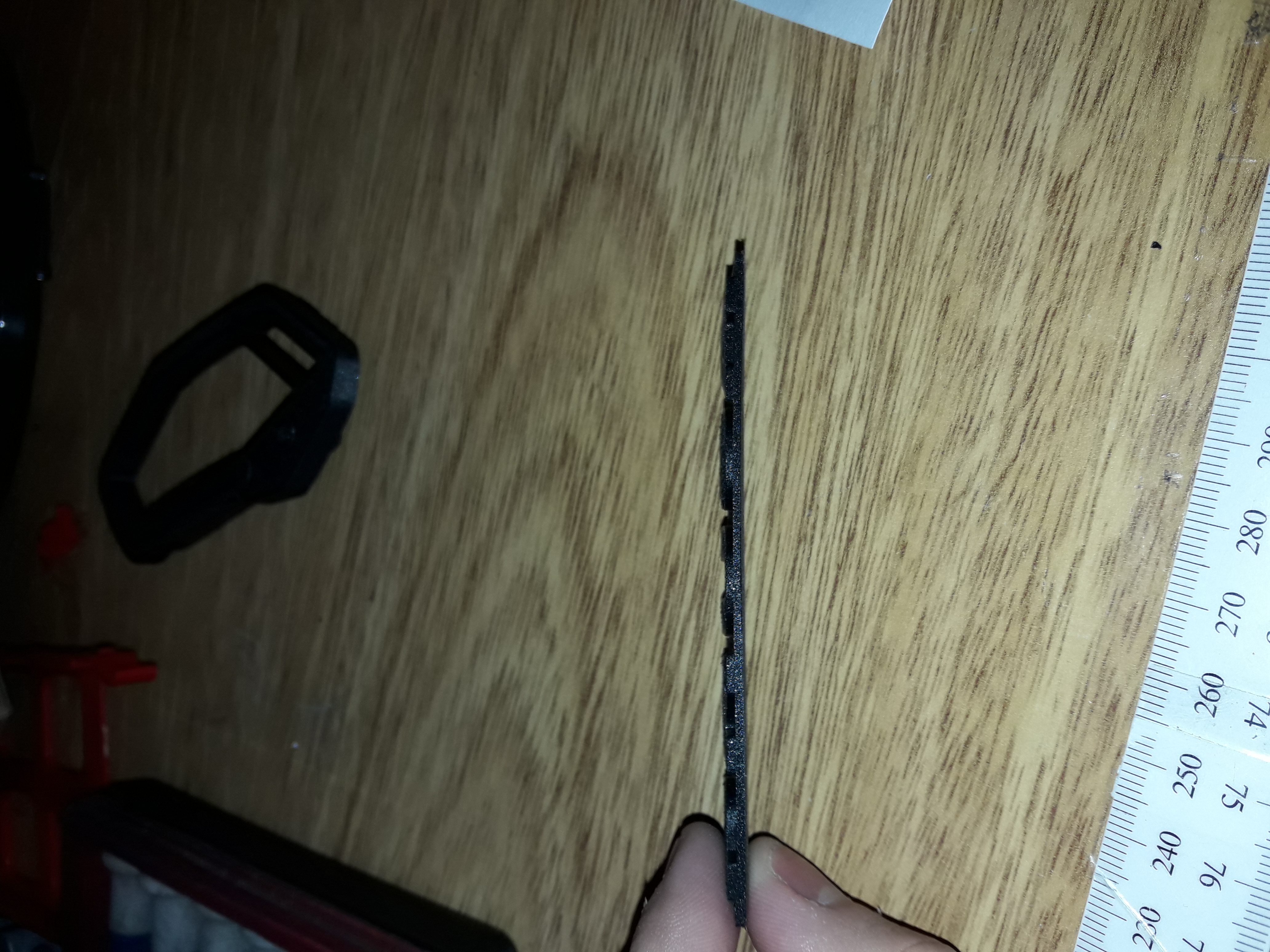

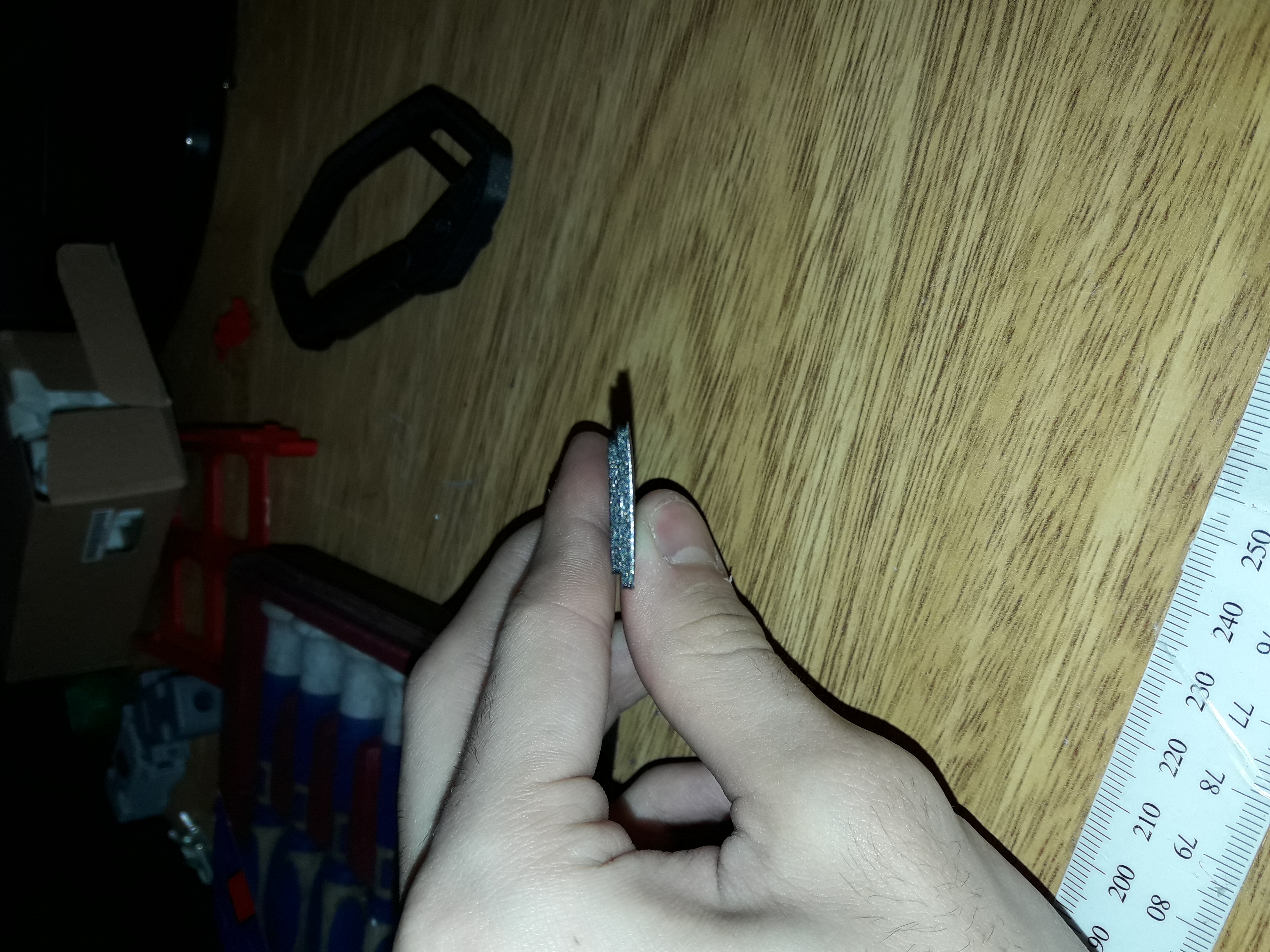

The print looks well, but if i look closer, the first layer it´s bent a little.

Print settings:

Nozzle temp: 260°C

Heatbed temp: 80°C

Fan: 0% (at all layers)

Speed:

Perimeters: 25mm/s

small perimeters: 15mm/s

external perimeters: 25mm/s

infill: 100mm/s

solid infill: 30mm/s

first layer speed: 20mm/s

I use Slic3r Prusa Edition.

Thanks for the help.

Re: Printing With NylonX

Are you using a glue stick on the print bed? I have not used that filament, but with Taulman 910 nylon I have to use a glue stick to get the first layer to stay down.

Re: Printing With NylonX

Yes, I used many diferents adhesives. Glue stick helped a little. But still warping, I´m using painters tape now.

Re: Printing With NylonX

When did you apply the glue? I have heard some people obtain different (better) results depending on if the glue is applied to a heated bed versus a cold bed.

Also, have you tried upping the bed temp a bit too? Say to around 90?

Also, what retraction settings (length, lift z, speed) are you using to achieve your (otherwise) good prints? 🙂

Re: Printing With NylonX

I apply the glue when the bed is hot. And used 100°C for heatbed too.

My retraction parameters:

Retraction length: 0.8mm

Retraction speed: 35mm/s

I used more adhesives. It got better, it´s nearly flat. Maybe the filament just cannot get that results. Against the logic, parts with bigger surface shows more bending than parts with less surface. I´m going to look if the nozzle is a little tigth to the bed.

Re: Printing With NylonX

Yeah, maybe that's as good as it will get 🙂

Re: Printing With NylonX

I have only printed a few things with NylonX but have been printing on glass with glue stick and it has been working really well.

-David

Re: Printing With NylonX

Hi , I´m printing with NylonX (Nylon + Carbon fiber), and i cannot get the piece well glued to the heatbed.

haven't tried nylonX, but I have used colorfabb cf nylon, and 3dxtech cf-petg and gf-petg with no adhesion issues and no brims whatsoever. The colorfabb honestly prints fine with no bed heat at all, the petg needs maybe 60c max.

it sounds like your part isn't adhering to the brim well enough if the brim doesn't lift at all.

Re: Printing With NylonX

I have only printed 3 times with NylonX, i use a glue stick (PRUSA) and i have kapton tape on top of my build sheet. i have had issues with some PLA not sticking well to the PRUSA build sheet so I put kapton tape on top. works well. glue stick applied when cold. 65-70 degree bed, 270 degree extruder temp.

Re: Printing With NylonX

Hey man, Send me an email, [email protected]

I have mastered nylonX on all my prusa machines and along with other machines. I can give you all of my profiles and recommend you an option for a new build surface. This was years and years of trial and error, so trust me when I say I highly doubt anyone is printing this stuff cleaner than me haha! but in all seriousness I have printed nearly 15 kilos of nylon X and bed adhesion is completely nailed at this point. Would love to help you or anyone out who is struggling with this stuff.

Thanks

Re: Printing With NylonX

Hey man, Send me an email, [email protected]

I have mastered nylonX on all my prusa machines and along with other machines. I can give you all of my profiles and recommend you an option for a new build surface. This was years and years of trial and error, so trust me when I say I highly doubt anyone is printing this stuff cleaner than me haha! but in all seriousness I have printed nearly 15 kilos of nylon X and bed adhesion is completely nailed at this point. Would love to help you or anyone out who is struggling with this stuff.

Thanks

What was the surface and what were your settings?

--------------------

Chuck H

3D Printer Review Blog

Re: Printing With NylonX

Hey man, Send me an email, [email protected]

I have mastered nylonX on all my prusa machines and along with other machines. I can give you all of my profiles and recommend you an option for a new build surface. This was years and years of trial and error, so trust me when I say I highly doubt anyone is printing this stuff cleaner than me haha! but in all seriousness I have printed nearly 15 kilos of nylon X and bed adhesion is completely nailed at this point. Would love to help you or anyone out who is struggling with this stuff.

Thanks

Your valued experience would be useful in the forum if you could post some of your settings and observations.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

Re: Printing With NylonX

What is the expectation for this part? Nylon is pretty flexible material. This parts looks like you could bend/twist it pretty easy with your hands.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Printing With NylonX

What is the expectation for this part? Nylon is pretty flexible material. This parts looks like you could bend/twist it pretty easy with your hands.

NylonX reportedly gets pretty stiff.

https://toms3d.org/2016/11/29/carbon-fiber-matterhackers-nylonx/

--------------------

Chuck H

3D Printer Review Blog

Re: Printing With NylonX

NylonX reportedly gets pretty stiff.

Agree. NylonX is much stiffer then regular Nylon. Anyway, look at the part. To me it looks pretty good printed and it should be still slightly bendable. That's why my question about the expectation. I don't think you could make it as stiff as metal/aluminum part.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Printing With NylonX

I want to use it for amature high power rocket parts.

--------------------

Chuck H

3D Printer Review Blog

RE: Printing With NylonX

@tony-d7

Could you send me the info on print settings for Nylonx. I what to start trying it out but it would help if I didn’t have to go through the trial and error phase. My email is [email protected]

Thanks

Jim

RE: Printing With NylonX

Two things. Buy a Garolite bed (there is a manufacturer on etsy) or make your own with a steel bed and a Garolite finish. I use mine COLD, otherwise Nylon sticks TOO MUCH.

Second thing: build some sort of "chamber" around the printer.

All your NylonX problems will go away. They have for me at least. Obviously print slow-ish.