Printing the Prusa Enclosure V2, issues, "bulging and delamination"

Dear Prusa community,

I'm currently working on the prints for the Prusa enclosure (version 2) and I'm encountering some issues during print.

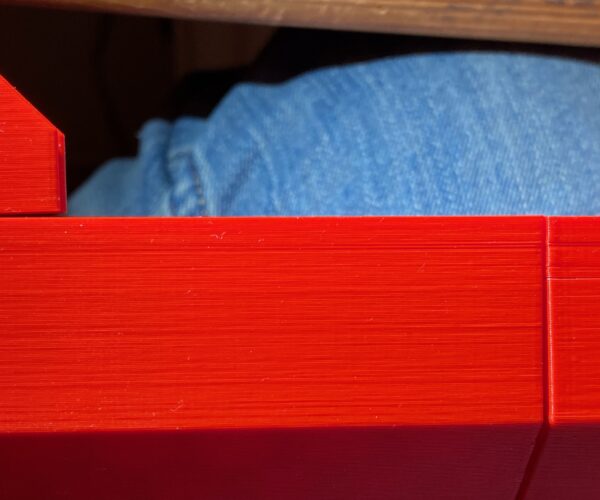

While printing the parts for the top-frame (5.3mf and 6.3mf files). I see some artefacts. When there is a (big) transition in geometry, or when you have solid layers you get the so called "bulging" issue. I used the Prusa profiles as provided in the 3mf files, which seem ok to me.

Secondly, I also observe layer delamination, especially when going from a large surface to smaller surface. e.g where the ridge for the acrylic glass becomes smaller). As you can see on my photo's. The profile has already 250 degrees celsius for nozzle temp which is also the highest temp recommended for my PETG.

Does anyone have some insight as how to tackle these issues? (Currently trying 5C higher nozzle temp (255) and increased flow from 95 to 100). I measured the filament diameter, which seems to be a consistent ~1,75mm.

Already a big thanks,

Kind regards

Bas

RE: Printing the Prusa Enclosure V2, issues, "bulging and delamination"

I think I am seeing slight layer shifting and I can see the delamination - looks like typical warping coupled with under-extruding? Try adjusting your extruder multiplier (upward). The thing you are calling bulging I call layer shifting. Check the grub screws on your X and Y pulleys, then check your belt tension.

RE: Printing the Prusa Enclosure V2, issues, "bulging and delamination"

@dan-rogers

Hi Dan, thanks for the fast reply.

Just a comment on layer shifting. If is was a shift it would probably be only in X or Y, but it is really a bulge in X and Y and on all sides. More over, it is protruding all around. Normally in a shift you would get a 'overhang' on one side and an indent on the other side. Which is not the case here. (screws are tight, and belts are according to the test spot on [250 for x and 253 for y]).

I did see more examples on other Prusa forum topics on this, for example the notorious benchy hul line).

About under extruding, that could be the case indeed for the delamination. I'm upping the flow as we speak, good suggestion.

kind regards