RE: Printing problem

I am starting to wonder if it could be a bad electrical connector, and when the print head hits a certain position it shorts out, I've had this happen after many hundreds of hours of printing on my MK3 machine with both fans and thermistors, as well as had power cables to my ensiy board come loose.

The Filament Whisperer

RE: Printing problem

@swiss_cheese

But it have happened now with 5 different print design so I think its not possible. I will check the connectors next.

RE: Printing problem

it is possible, that its the heat break, I knew of this before I built my MK3s and I bought the genuine E3D heat break as my MK3 has.

But i would exhaust all other possibilities first, before taking the printer apart.

The Filament Whisperer

RE: Printing problem

@teemu-anttila

I hate to break it to you, but there are literally tenth of thousands of Prusa printers printing all sorts of filaments all over the world. It's pretty safe to say it's not the heat break that is causing problems it's your heat break. Or something else with your printer.

You should consider taking the extruder and hot end apart and check if there is something wrong. Perhaps the PTFE ist worn out on the lower end or something else. There is something wrong, it's just not that easy to find and fix it...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Printing problem

@teemu-anttila

I would agree with Robin, I think at this point if you have eliminated the basics as queried above and are sure the extruder is ok then I would strip down the hotend and look for the cause.

Guide to replace the PTFE tube is below if it helps (careful with the black collet, breaks easily) while on the subject of this, was the ptfe tube locked so doesnt move during build, I almost missed this step, it is in the PTFE Guide step 8)

https://help.prusa3d.com/en/guide/how-to-replace-a-ptfe-tube-mk3s-mk2-5s-mmu2s_21664/

Also E3D assembly guide if it helps, (slightly different as PTFE tube is different and no clip under black collet)

https://e3d-online.dozuki.com/Guide/V6+Assembly/6

Tank you very much!

RE: Printing problem

@teemu-anttila

Was the PTFE tube locked into place with the black collet? Or was it able to move a little?

Tank you very much!

RE: Printing problem

@clarmrrsn

It was locked with black collet didn't move at all.

RE: Printing problem

That seems to rule the PTFE tube out then, I would fit a new one anyway if you have one in the kit, maybe worth delving a little deeper if you still have the hotend out.

Maybe put fresh heatpaste the heatbreak and inspect it for any visible damage.

There is also a troubleshooting document from E3D, maybe worth a browse

V6 Troubleshooting - E3D-Online (dozuki.com)

Tank you very much!

RE: Printing problem

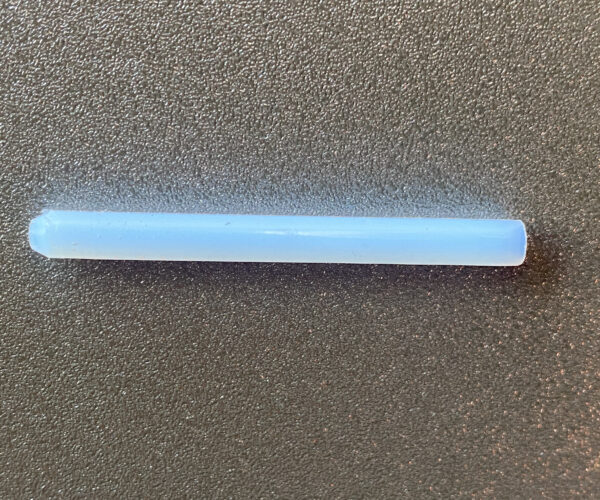

[...] Here is the picture of melted filament diameter 2,2mm so it has melted in the area that it should not happen.

I know that the heatbreak has been pointed to as the smoking gun ever since the 3D Printing Nerd video came out, and it's great that people are getting everything working by replacing their Prusa-fied 2.2-2.0mm modified heatbreak, but I really think this misses the underlying issue. How the hell is filament getting soft enough that high in the heatbreak to deform from 1.75 to 2.2mm in the first place? Something has to be wrong, particularly if you are sticking to the E3D recommendation to keep retractions below 2mm for the V6 all-metal hotend with direct drive. I think it's a mistake to not address the underlying heat issue that is allowing filament above the heatbreak to get so soft.

Particularly for a kit build, I'd verify that thermal paste was properly applied to the hotend, that hotened cooling is working (incl. verifying fan direction) and that ambient temps are 40C or below before tearing anything major apart.

I replaced my heatbreak after 18 months, but only because I was doing a teardown and went ahead and replaced it with a Titanium version.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printing problem

Have you checked the heatsink cooling fan is working correctly and that there are no obstructions to the airflow?

RE: Printing problem

@3delight

Yes its running ok and all clean.

RE: Printing problem

@bobstro

I have tried retruction 0,4-0,8 temp 240-260, extrusion multiplier to 1.0-0.92, thermal paste is ok, fan is working and is installed in coorect direction, nozzle is installed correctly... all should be ok.

when I go for a long printing where priterhead moves small distances the problems start. I can print easily 10 hours if the printing model is simple. All problems starts with small details. First starts a bit srtinging and some minutes after that it jams. So in my opinion overheating is the problem that jams the filament on heatbreak.

RE: Printing problem

[...] when I go for a long printing where priterhead moves small distances the problems start. I can print easily 10 hours if the printing model is simple. All problems starts with small details. First starts a bit srtinging and some minutes after that it jams. So in my opinion overheating is the problem that jams the filament on heatbreak.

Oh, I don't disagree that heating is the issue at all. Over the years, we tend to see a LOT of these issues pop up. I have to run right now, but I've captured notes here that might be helpful. There are 2 distinct "heat" topics: Upper and lower hotend. Both can cause problems. I'll reply in more detail soon.

Quick question: I didn't see this noted above. Does this only happen with PLA? Are you able to do long prints with PETG?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Printing problem

@bobstro

Im printing only PETG... so thats pretty weird this happening...

RE: Printing problem

This certainly seems to be a weird one! So let's get this straight:

- As far as you can tell all parts of the printer are working OK.

- You can print something 10cm tall but narrow like a thin cylinder.

- A large object will fail at around the 5cm mark?

- You print just in PETG.

- The printer thinks it's printing but no filament is extruded.

- Pushing the filament deeper into the extruder housing starts it extruding again.

A couple of basic questions o get out of the way:

- Have you tried reslicing the model?

- When it goes wrong are you able to gently pull the filament up out of the extruder while it's still trying to print?

- Have you tried lowering the temperature?

- Was the PTFE tube the right way up?

- What model do you own (MK3, MK3S, MK3S+)?

RE: Printing problem

@3delight

Yes all things are just you said.

and then:

1. Yes I have resliced and tied different setups.

2. I have not tried this

3. Yes I have tried lower.

4. PTFE tube was deep in and all the way up near gears.

5. MK3S+

RE: Printing problem

I've re-read through this thread, but want to verify a few things:

General

- What layer heights are you printing at? I find < 0.15mm tricky and jam-prone with PETG.

- When it jams, is there filament stuck below the Bondtech gear in the extruder? Can you pull everything out including the part with the extruder gear marks and hotend impression? If it all comes out, that points to a lower hotend issue. If it snaps off at the top of the PTFE, that points to a higher extruder temperature issue.

- Just to eliminate the obvious: Are you printing in an enclosure or at temps above 40C ambient? Air flow is very important in an air-cooled system, particularly if ambient temps are increasing.

- Are you printing parts with lots of little extrusions? (Looks like yes.) What settings are you using under Printer Settings->Extruder 1->Retraction (if not default)?

Extruder heat

- Do you have good airflow around the upper extruder area?

- Does your extruder motor get very hot? Is it cooler in areas of the print early on with fewer retractions?

- Have you tried increasing Printer Settings->Extruder 1->Retraction->Minimum travel after retraction? This will avoid retractions if there is very little movement. I set it to 2 but it looks like the Prusa default is 1. Increasing this value will reduce the number of closely spaced retractions, reducing heat.

- Have you tried reducing Printer Settings->Extruder 1->Retraction->Deretraction speed? I've set mine to 25mm/s. This feed filament back after retraction with less of a "hammer" speed, reducing heat.

- Some folks report good luck reducing extruder motor heat -- and associated "heat creep" from the motor heating up the top extruder area -- by cooling the motor with heatsinks and/or cooling.

Hotend heat

- It sounds like you verified the thermal paste & hotend fan orientation. That should reduce "heat creep" from the hotend up into the cold zone.

- Have you done a cold pull? Can you get a good impression of the inside of the hotend and nozzle? This helps check for obvious crud and misalignment. (I had a crappy bimetal heatbreak cause all kinds of issues due to inside machining.)

- Are you using cooling? PETG is very finicky with temperatures.

The heatbreak replacement works for many people, but it can get things working while not resolving other issues that might come back to haunt you on warmer days.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…