Printing L shaped part allways fails

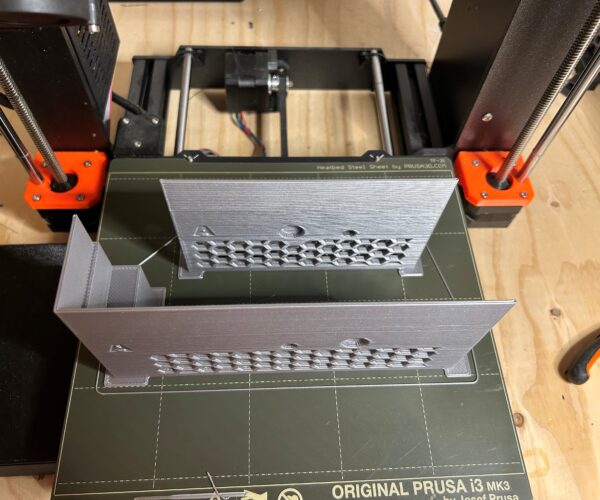

Been trying to max out a part and using as much of the printing area with a 20x23cm L shaped design.

But, no matter how I try the ends lifts and I get a crooked print.

Tried adding extra holder at the end and using 0.8 nozzle but still the same problem:

Is it just PLA that bends so much, should I go to PET?

RE:

You're going to have the same problem with PETG. Large parts like this are just not easy to print. Here's my crip sheet of warping mediation strategies:

Assuming your Live Z is spot on, and the sheet has been thoroughly cleaned with 90+% IPA:

- Slow down print speed.

- Add Mickey Mouse ears to the corners. There's a "helper disk" in PrusaSlicer's Add Part library, or you can simply add a cylindrical, maybe 10mm diameter, change height to single layer height, then place the part at the corner. Repeat for each corner.

- Add a brim around the model, 5 mm or more. Wider or 2 -layer high brims may be needed but may not work with the size of the model or may require being added in your CAD software.

- Use Layerneer Bed Weld ( https://www.amazon.com/Printer-Adhesive-Layerneer-Original-Filament/dp/B079984GV5/ ). You only need a thin layer.

- If you have design control over your part and it's possible considering the intended use, you can try to round the edges and/or add holes to the base of the model.

- Combination of above.

- Usually, brim/ears does the job, or some Layerneer if needed, but large, rectangular objects can be a challenge. Also, drafts can encourage warping, so printing in an enclosure (with doors open for PLA) may help.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printing L shaped part allways fails

Please don't be afraid of using an adhesion booster such as Layerneer. I swear by it, and it works very well with PLA. It also works quite well as a release agent, particularly for PETg/ABS/ASA prints.

For a large print, you can probably get away with just putting it on the parts of the build plate where the edges of the print will hit.

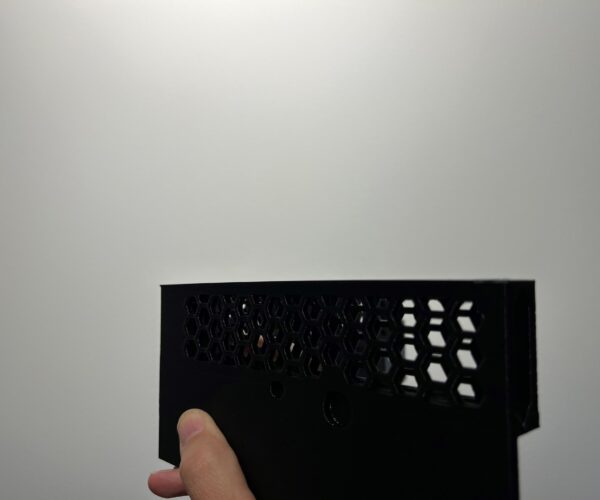

And I've found that, in general, PLA is far more well-behaved with large flat prints than PETg or ABS. ABS is probably the worst, as it naturally shrinks when cooled. I actually had one ABS print crack as it was cooling, before it released from the build plate (below). (This was not on a Prusa.)

RE: Printing L shaped part allways fails

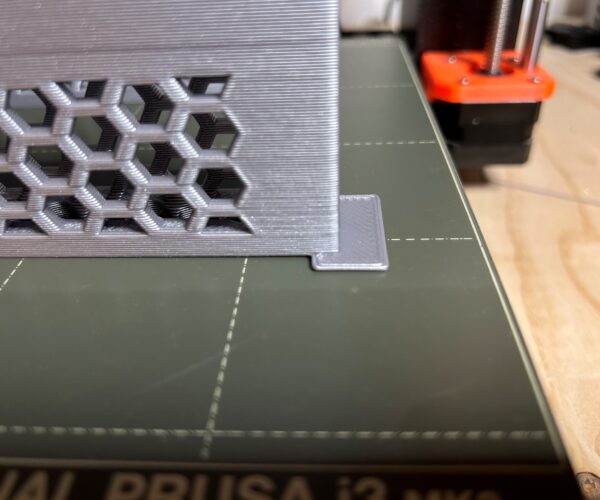

Redid it in two parts and got really good adhesion, till I popped the parts from the bed.

As shown in the lower picture the part bends as its detached from the bed.

Think the design has en uneven horisontal strength, somehow.

Anyway redesigned it, new test will be done soon.

RE: Printing L shaped part allways fails

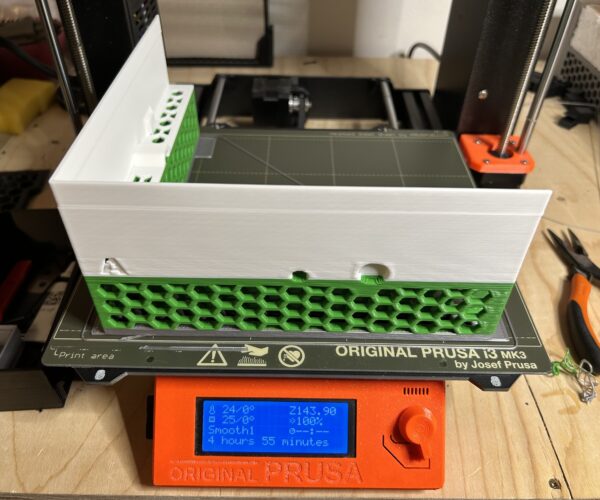

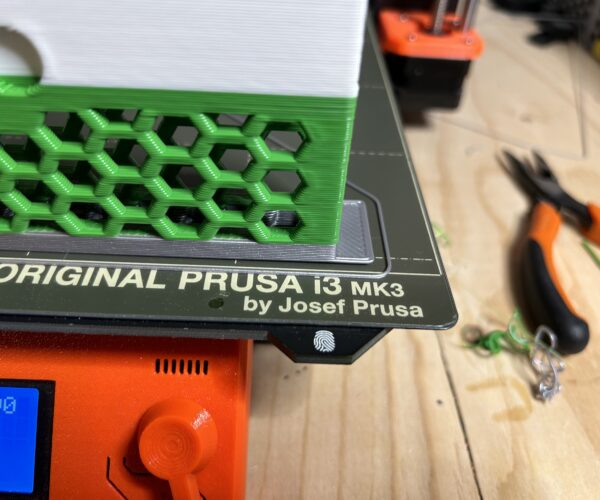

Reprinted with new airier design, still got the lift in the corners, gotta but some Layerneer and test…

RE: Printing L shaped part allways fails

You could, as an alternative, try the Kores (or similar) glue stick.

Some people swear by hair spray, and there is some evidence that Layerneer is actually a repurposed hair spray product.

RE: Printing L shaped part allways fails

Realized I had a Kores stick from when I bought the printer...

Been thinking (looking at Youtube) for how it all works and I suspect its more thermal than just adhesion.

Going to lower temperature and speeds on the first layer and maybe even turn off the bed heating, I´ll be back with the results.