Printing ASA for the first time - tips?

I am going to try to print a gear today in ASA. I have a MK3S+ in a heated / insulated enclosure.

For a structural gear, what % infill would you advise?

Is there a particular infill pattern that works better for ASA?

What ambient enclosure temp would you advise? (I can get it quite high with my setup, but am worried the printer parts will droop if I go too high)

Thanks!

-Joe

RE: Printing ASA for the first time - tips?

I forgot to mention, this is the filament I will be using:

https://www.amazon.com/dp/B0B1DF9273?psc=1&ref=ppx_yo2ov_dt_b_product_details

Which filament settings would you start from in slicer? Prusament ASA?

RE: Printing ASA for the first time - tips?

I've printed a fair bit of polymaker ASA. Always used the Prusament ASA profile. Never had a problem with it. If you want strength I would go with 20% gyoid or cubic infill and 3 or 4 perimeters, but it really depends on the model.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printing ASA for the first time - tips?

What size gear(s) are you printing?

I have done quite a few gears over the past few years, using both pre-made .stl files and the Involute Gear tool of FreeCad.

The larger gears are trivial, and I've done those in ABS/ASA and PLA with excellent results.

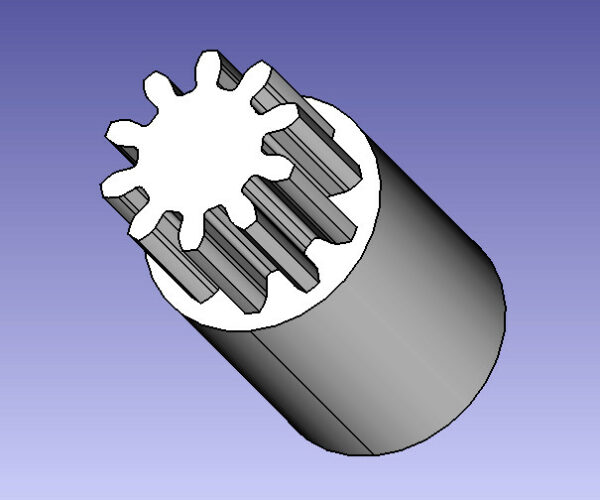

The smaller gears tend to be tricky. The smallest I've successfully printed which was robust and worked as intended over multiple years is shown below. This is about 8mm tooth diameter on a 10mm shaft.

I test-printed this in PLA, PETg, and ABS, with PLA giving a slightly better tooth detail than ABS. The PETg test gear was nasty, unusable. Too soft and too many artifacts preventing a good mesh.

It's for a modified automatic flush valve, and has been in a warm wet environment for a few years now. It's still working.

RE:

It is a 34 tooth 10 Pitch gear that will be used as an antique automobile speedometer drive. Gear was designed using Fusion 360 Gear add in. The gear is 0.315" thick and about 3.5" in diameter. My fiurst PETG print of it was not satisfactory, but I was using 100% infill.

RE: Printing ASA for the first time - tips?

My starting point for this would be 25% gyroid infill, 3 perimeters, 0.3mm layer height. 25% should be enough to avoid pillowing of the top surface. For more strength, I'd add more perimeters, not infill.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Printing ASA for the first time - tips?

It's been printing for a little while.

I went with 30% Gyroid infill and 7 perimeters. 7 perimeters ensured the gear teeth and their root was solid. That felt right to me.

Bed is at 110C

Nozzle at 260C

Chamber is hovering around 38 - 39C.

I think the layer height I used was only 0,15mm because that is what I normally use, but there is no vertical detail on the part at all, so it could have been higher than that and printed faster. Hopefully that doesn't screw anything up.

I did, stupidly, decide to upgrade the firmware from 3.11 to 3,13 just before this print and that was a major mistake. I fought it for 2 hours and ended up having to revert to 3.11 and do all my cals again. I don't think I got my first layer Z perfect, nozzle probably could have been a smidge closer to the bed. It hasn't peeled up yet and the print is 40% done. Hopefully it sticks until the end.