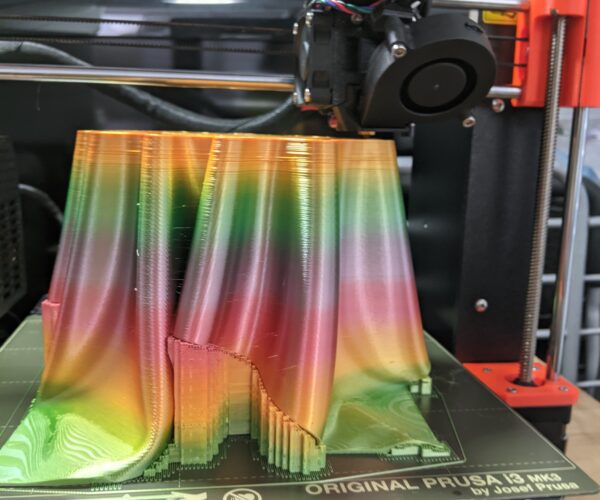

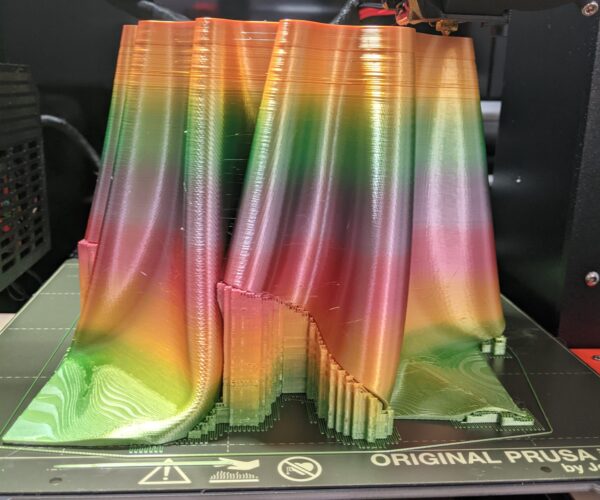

Print quality problem at higher layers

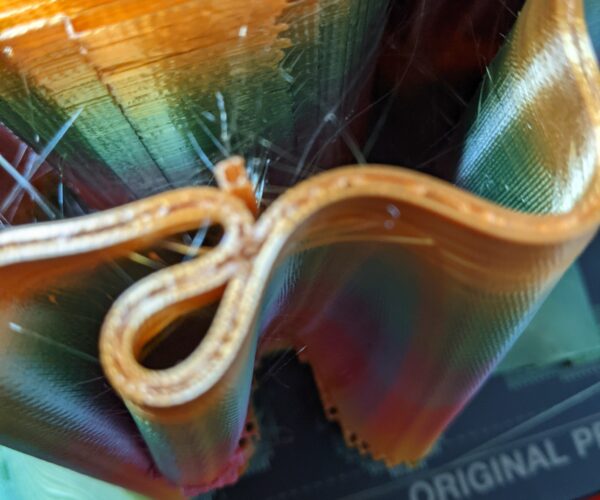

This is a brand new printer that passed calibration with flying colors. It's my first "big" print on it. Hopefully, it's clear from the pictures that it's been printing well (stringing aside) for over 2 days now. Then I noticed the quality took a dive when it hit the yellow portion. Also, not sure if it's clear from the pictures, but there appears to be a little additional printing on the inside. I'm not sure what happened. Any assistance would be appreciated.

Printing at 205/ 60 with some random rainbow silk PLA that I probably got off AliExpress.

Check to see if changes correspond to internal structural changes, check bed adhesion, slow down

Does the change in appearance correspond to internal changes (e.g., changes from gap fill to sparse infill, additional perimeters) by any chance? If so, search on the term "buldge" (yes, it's dumb) for several lengthy discussions. Adjusting perimeter widths and count can help minimize side effects from internal structural shifts.

A tall part can start to wobble a bit as you get to higher layers. This print looks tricky with all the supports. Be sure your bed adhesion is solid (inspect the underside of the support) and look for any slight lifting that can be amplified at higher layers.

Slowing down can often help. Dial speed back 50% and see if flow evens out and mechanical-induced defects are reduced. This looks like it might be a heavy print, and that weight has to be slung around on the bed, particularly for Y moves. Tuning acceleration and jerk may help if this is the case.

Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

I'm honestly not sure for a lot of this

It's a pretty thin model, and it does seem to be getting thinner around there. I'm not smart enough to have saved the project file, the gcode is only on the card in the printer, and I'm sure I've been playing with the slicer settings.

All that said, I guess I wasn't expecting vibration to be an issue, as I printed a model where bits would always fall off the supports (even sliced with PrusaSlicer) when printed on my Creality CR6 and didn't have any problems. I don't like the way the spool is jumping around on the spool holder and def need to print a guide so I can move it to my drybox.

I just changed the speed to talk to me next week (pleased to see the time remaining display updated), so I'll see how that goes.

The other stuff I'll have to research. I did see the mention of bulging and sparse infill scattered about the forum, but I'm not as smart as I think I am, so I thought it was work an ask.

Thanks so much for your help.

Speed and other settings

[...] All that said, I guess I wasn't expecting vibration to be an issue, as I printed a model where bits would always fall off the supports (even sliced with PrusaSlicer) when printed on my Creality CR6 and didn't have any problems.

Are you using the same speeds with both printers? You can try mirroring the CR6 speeds on the Mk3 and see if that helps. It's not only vibration, but (sometimes) also rate of acceleration and jerk that make a difference.

I don't like the way the spool is jumping around on the spool holder and def need to print a guide so I can move it to my drybox.

Uff. Definitely yes. I cringe when I see someone bragging about putting a 3Kg spool on top of the printer frame.

Good luck with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Speed about the same, I haven't really messed with acceleration/ jerk

The speeds for both printers are in the 40-50 range. After about an hour on the slower speed, it's hard to tell if there's an improvement, though I don't see a discontinuation in the mystery artifact. I haven't messed with the acceleration and jerk settings. What I'm finding interesting, though, is that, as I hover my mouse over many settings in PrusaSlicer, it tells me that the default is different from what is set, even if I haven't made any changes.

CR6 def printed the same model at about the same size, though with tree supports, so much lighter, and it looks perfect. I feel like some of these cheaper filaments don't do great at smaller layer heights and that might be part of the problem. Or I might be imagining things.

Bed adhesion doesn't seem to be a problem. I always print on PEI and rarely have problems. During the first layer calibration, I couldn't figure out how to lower the nozzle (left handed, so lefty loosey/ righty tighty is beyond my comprehension sometimes) and the lines printed from 1/4 inch up stuck pretty well.

Anyway, thanks again. Warning, I've been sitting alone on my couch for almost a year and a half now, so if you reply, you WILL get a reply back!

Silk PLAs can be a pain

The speeds for both printers are in the 40-50 range. After about an hour on the slower speed, it's hard to tell if there's an improvement, though I don't see a discontinuation in the mystery artifact. I haven't messed with the acceleration and jerk settings.

If slowing it down doesn't fix things, don't worry about the acceleration & jerk settings. 40-50mm/s is reasonable, but I do use 25mm/s for external perimeters when I care about final finish. Many filaments have a range of speeds at which they print well that is well below what the printer can handle. I find silk PLAs a real pain to print with myself.

[...] What I'm finding interesting, though, is that, as I hover my mouse over many settings in PrusaSlicer, it tells me that the default is different from what is set, even if I haven't made any changes.

A lot of those defaults go back to versions of Slic3r from nearly 10 years ago, I think. I wouldn't worry too much about those. Prusa has tuned their presets pretty well.

CR6 def printed the same model at about the same size, though with tree supports, so much lighter, and it looks perfect. I feel like some of these cheaper filaments don't do great at smaller layer heights and that might be part of the problem. Or I might be imagining things.

If you want to save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

Bed adhesion doesn't seem to be a problem. I always print on PEI and rarely have problems. During the first layer calibration, I couldn't figure out how to lower the nozzle (left handed, so lefty loosey/ righty tighty is beyond my comprehension sometimes) and the lines printed from 1/4 inch up stuck pretty well.

Just remember more negative is down (nozzle closer to bed)!

Anyway, thanks again. Warning, I've been sitting alone on my couch for almost a year and a half now, so if you reply, you WILL get a reply back!

LOL. I do this while idling on conference calls.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

3mf attached

OK, I have been messing with the settings. Mostly retraction, to try to deal with that stringing, and maybe some Z offset on the supports. But really who knows what I've gotten into my head to fiddle with. I can be impulsive (see, 3 day print before printing filament guide). But the time and filament weight are pretty close to what I got on the slice, so if you're bored/ curious, have at it. Lots of people find this stuff fun, and who am I to argue.

And I knew that negative was the right way, I just couldn't get it to go that way. My extruder is defective in some weird way that means the IR sensor only works if the top screw behind it is loosened about 1.5 turns, because my life is drama, though.

Thanks, again!