Print "block"

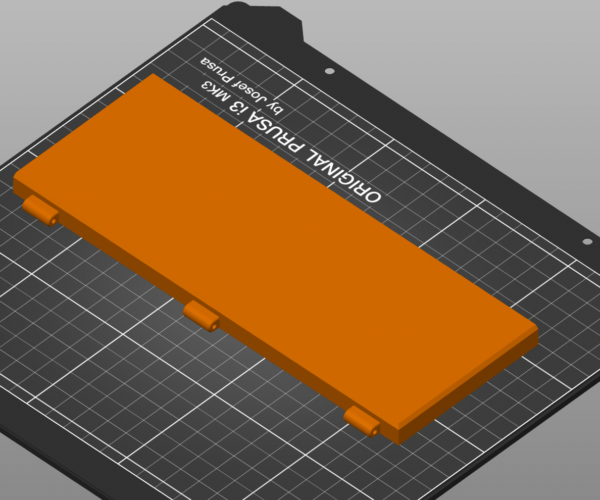

Have some files I want to print, it takes about 4 hours to print 1. I have 12 in total, the only critical thing is the small holes on the side. What I want is for the sides to be straight so I can glue them together. i am using PETG

Haven't messed around much with settings in slicer, so don't know what can be done. run with 0.6 nozzle

RE: Print "block"

The most critical Thing i see is that your part consists of 40 % internal infill. What is your %-setting for infill?

Usually 15 - 20 % infill is sufficient. For stronger parts add more perimeters and top / bottom layers.

RE: Print "block"

Not sure what the specific question is. The critical part is the hinges. From the photo it's not clear to me whether their base sits on the sheet or there's an offset like from the top surface. In which case you'd be printing in thin air. The holes will probably be slightly deformed and may require being drilled out. The hinge quality would be improved with a smaller nozzle and lower layer height but that will add time to the rest of the model. Conflicting priorities.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Print "block"

Yes its take some time. i have it om 20% infill at the monet, but want to get a print faster, and using 0.15 setting, i just using it to get the hinges good, and even using support for it.

RE: Print "block"

they hinges are on the side, so i will need to use support on them.

yes that holes are getting deformed and use drill is hard, in the middel on, wonge angel

RE: Print "block"

yes that holes are getting deformed and use drill is hard, in the middel

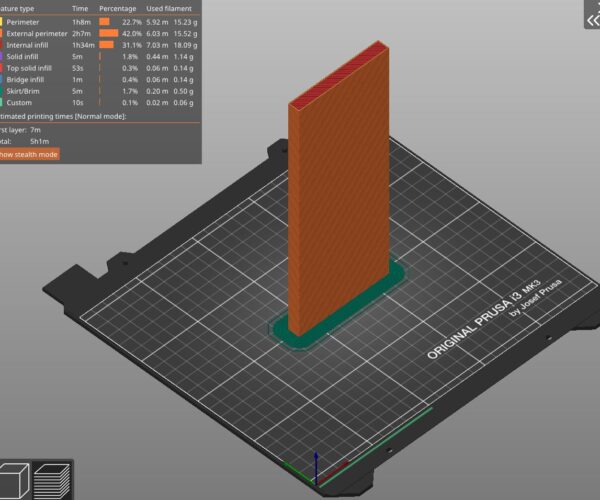

if Z-height is sufficient, one idea would be to orient it like this:

requires support for the hinges (not displayed in my picture), but hinges will be strong and holes are circular and you can get it right without drilling.

However, the risk is that the print loosens, so print slowly, use brim.

RE: Print "block"

The most critical Thing i see is that your part consists of 40 % internal infill. What is your %-setting for infill?

Usually 15 - 20 % infill is sufficient. For stronger parts add more perimeters and top / bottom layers.

how can i change that, dont fells like i dont need that, and its taking alot of time to get 40% internal infill.

I think i will prit it laying down, using support, for the hinges and trying to get down on thte internal infill some how. and just start to print. Dont know what settting to use

0.15mm, 0.20mm, 0.25mm and so on, using a 0.6 nozzle

RE: Print "block"

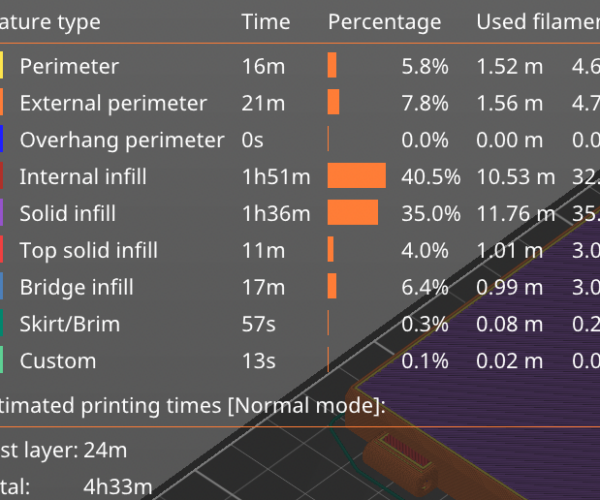

40% internal infill

here i meant the "used filament percentage" that is shown in the legend top left.

It was a spontaneous impression to me, but might be not so far from a somewhat usual value (it always depends on the part geometry)

You can only influence it in Print settings> Infill >Fill density and Fill pattern. When printing it laying flat, you cannot go much less than Fill density 15 %, because the top layer would sag.

If you are not "shy" of the layer lines and want to save time, 0.3 layer hight is fine for 0.6 nozzle.

RE: Print "block"

40% internal infill

here i meant the "used filament percentage" that is shown in the legend top left.

It was a spontaneous impression to me, but might be not so far from a somewhat usual value (it always depends on the part geometry)You can only influence it in Print settings> Infill >Fill density and Fill pattern. When printing it laying flat, you cannot go much less than Fill density 15 %, because the top layer would sag.

If you are not "shy" of the layer lines and want to save time, 0.3 layer hight is fine for 0.6 nozzle.

What pattern do you think i should use? now i am using gyroid, i did change the Fill density to 20%, and going to use support. I haven't tried the new update (beta) maybe is a good ide to update and then print?

I am using revo 6 on my machine