Print a reproduction mesolithic pendant

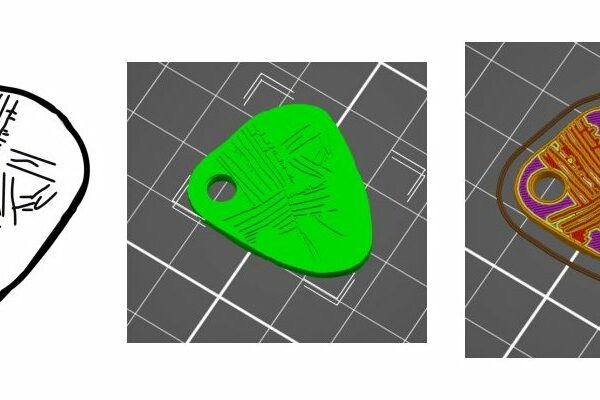

I am a relative novice both in CAD and 3D printing. I am looking for advice in printing a reproduction of a Mesolithic pendant (this is from the Star Carr site in Yorkshire). I am primarily interested in reproducing the lines on the surface. I’ve traced the image as a PNG file and converted this to an STL file and then used Prusa slicer to generate the gcode. I used .05mm layer thickness.

I decided that 3D printing, certainly at my level of competence, was not appropriate (though I am happy to accept advice to the contrary).

I then decided to try to produce a die which I could use to “print” the pattern into modelling clay or something suitable. I then created two STL files, a shape cutter to cut out the pendant outline, and a die with the pattern, to stamp the shape onto the cutout. The outline cutter is straightforward, but the die is trickier. These are the STL, the sliced die on Prusaslicer, one of the 3D printed dies, and some of the stamped parts. I used .05mm layer thickness, and checked detect thin walls and bridging parameters.

The die is not great, so the printed parts are not brilliant either. I am wondering if there is anything I can do to improve the quality of the die, or am I pushing the technology too far.

All suggestions welcome

A soft answer turns away wrath.

RE: Print a reproduction mesolithic pendant

With that model you could slightly thicken the lines using the xy compensation in Prusa Slicer but for the detail going to a smaller nozzle size like 0.25 might be your best bet.

RE: Print a reproduction mesolithic pendant

@neophyl

I don't have a smaller nozzle. But that certainly makes sense. At this stage, i don't to start changing printer hardware I'm doing tbis for fun!

I can have a look at xy compensation.

Thanks

A soft answer turns away wrath.

RE: Print a reproduction mesolithic pendant

I should have given a size indication. Its about 30mm fro x and y - a couple of mm thick

A soft answer turns away wrath.

RE: Print a reproduction mesolithic pendant

Hi just try to slice il with 0.25 nozzle profile to see the difference on screen, maybe it will convince you to change your nozzle which is a quick and simple operation.

MK3S & Fusion 360

RE: Print a reproduction mesolithic pendant

I've only printed less than a dozen things so far so no expert here.

I tried printing something which was very small at 0.05 with PLA but it didn't turn out very well, think it was getting too hot and the previous layer was slightly deforming which became exaggerated as the print progressed.

I got much better results at 0.1mm layer height, I used standard Pursaslicer settings and only added a 5mm brim. I tried detect thin walls but the preview showed it lost details so switched that off again.

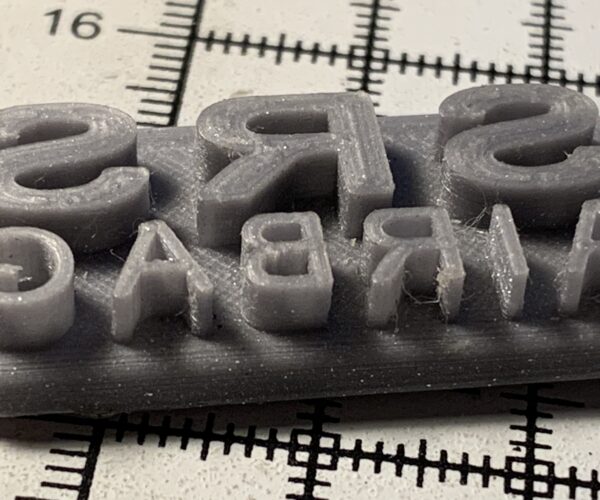

I've printed a stamp for use on leather, similar to your die idea. I did a bit of adjustment in CAD to ensure the thickness of the letters were printed without infill which made the top surface look a bit shaggy. I guessed at this before reading this article about walls and perimeters which you might find useful:

https://help.prusa3d.com/en/article/layers-and-perimeters_1748#recommended-thin-wall-thickness

The letters of airbag on the photo measured with a micrometer are 1mm thick. I probably could have got it to print a bit better but it worked fine on the leather so didn't worry further. If you have a look at the shells as per the article I think you could get them thinner than mine.

If you can it might be better to have a thicker base with a brim so it doesn't lift and give the potential of filament sticking to the nozzle where its lifted which then gets carried to the rest of the print. I've found making sure the nozzle is absolutely spotless with a magnifying glass after something goes wrong really helps next attempt.

I intend to do other very small things so have a 0.25mm nozzle on order to see what I can do with that, should be easy to change and around the £6 mark I think worth the investment.

Good luck!

RE: Print a reproduction mesolithic pendant

A fascinating project. I can only imagine what those marks may have meant to someone to warrant carrying closely.

I can understand your hesitancy to muck with hardware for a bit, but don't put off trying new nozzles too long. They really open up creative opportunities.

Experiment in the slicer with different nozzle sizes and view the results in preview mode. While you might need something smaller than a 0.4mm, you'll want to stay as large as possible to avoid unnecessarily slow prints. I've found a 0.25mm sufficient for the finest details I need in 1:100 scale miniatures.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Print a reproduction mesolithic pendant

I should explain my reluctance to mess about with hardware. I bought an MK3 kit last summer (2019), assembled it and it worked fine for several months. It then developed an intermittent fault where it would stop extruding at arbitrary points in the printing process. I spent hours in online chats with Prusa advisers, taking apart things, replacing things, adjusting things to no avail. I also had long conversations in the forum. You may remember me @bobstro! Eventually, Prusa recommended that I send it back for repair and service. I paid for this and got it back, supposedly in full working order. It now had a new permanent fault where the extrusion went through a 30 second cycle where the printing output came and went. After yet more chats with advisers, Prusa agreed to replace the printer with a new assembled one. I got this in April of this year, and it has worked perfectly since that. So I really don't want to meddle with anything while it is still working! Maybe when I have exhausted all the things I can do with the current nozzle, I will think about changing. Or of course, when it stops working......

But will read through all the suggestions and see where I can get to with what I've got.

Thanks all.

A soft answer turns away wrath.

RE: Print a reproduction mesolithic pendant

I should explain my reluctance to mess about with hardware. [...]

I remember your plight well. You were incredibly patient and good natured about it. I'm glad Prusa got your sorted out. Go at your own pace, but don't hesitate to ask any questions as you get more adventurous.

I really like this project. It's something that educators might find very useful. I was always fascinated by anthropology as a kid and wish I'd had access to "hands on" resources. I like your idea of creating molds that can be used to easily and reliably create replicas out of clay.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Print a reproduction mesolithic pendant

@bobstro

You will find information here about Star Carr

There is also a FutureLearn (one of the MOOC service) aboutiit which I have been doing.

They don't know what the lines are for either!

A soft answer turns away wrath.

RE: Print a reproduction mesolithic pendant

Update: I realised that I did not need to make the lines in the pattern as deep as as I doing - the lines on the original pendant were very shallow. So I made a die with smaller cutting lines, and the results are much better. But now I need to work on my pottery skills!

A soft answer turns away wrath.