PMMA cracks after clear coating

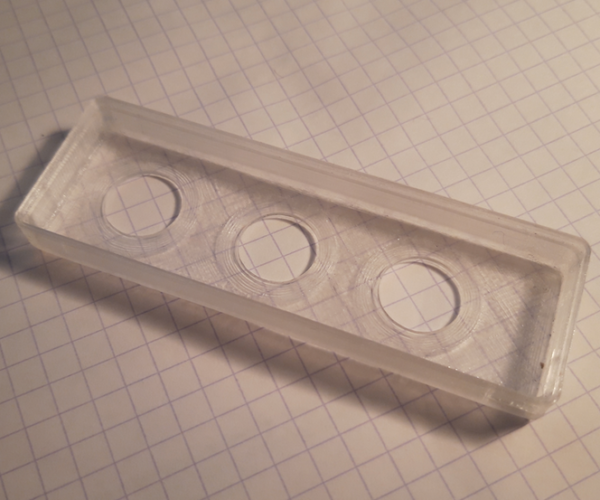

Hi, i'm printing following part with PMMA filament (i'm looking for a translucent surface, as clear as possible). After some tweaking i was able to achieve sufficient translucency, but i have another problem - when i paint this part with clear coat, it cracks in all four corners without any intervention. I examine it before painting (about 12 hours from printing) and it's intact. Then i check it after few hours from painting, and cracks are there (example is visible on second attached image). These cracks are not even aligned to print layers, they go along few layers of material.

Does anyone have similar experiences with PMMA? Can this be somehow related to solvent present in spray paint?

Never heard of PMAA - how did you get it so clear (settings please)

It sounds like your spray paint is a solvent (which it is, that's how the acrylic gets dissolved in the can) and your part is too thin to withstand a soak in solvent.

Re: PMMA Settings

Yes, it's probably solvent. I have ordered water based clear coat and i'll see if this solves the problem.

As to PMMA and translucency - it is pretty translucent without any tweaking, but it tends to produce microscopic bubbles on a first layer, which spoils translucency by adding whiteish areas/spots to first layer. This effect is reduced when i lower the temperature of the first layer to 240C (PMMA recommended print temperatures are around 255C). Then i quickly ramp up temperature to 260C - lower temperatures produced objects lacking strength, very easy to break/crack/delaminate. At this temperature there will be some stringing, but not too much - it needs some post processing anyway.

So roughly:

- Lower Z to get flat/smooth first layer surface. i don't have problems with it sticking too much - using normal PEI steel sheet without any glue.

- 0.1 mm layer height (i needed fine detail for this project)

- Temperatures: bed: 100C, nozzle: 240C/260C - first layer/next layers. I'm using Nozzle X E3D V6, temperatures should be probably slightly lowered for brass nozzles.

- Print slowly

- Post processing - remove strings, artifacts, treat upper layer with fine sand paper, then clear coat.

fumes

Yet another thing - it produces nasty fumes. Use enclosure, or do not stay in the same room while it's printing, and ventilate well after.

Cracks

I would agree with has to be solvent related. I would choose a paint that you can confirm is Acrylic or PMMA compatible. Maybe Acrylic based paint.

--------------------

Chuck H

3D Printer Review Blog